Insert structure for injection moulding

A technology of injection molding and inserts, applied in the direction of coating, etc., can solve the problems of affecting product appearance, injection molding defects, cracks, etc., and achieve the effect of improving injection molding defects, increasing production competitiveness, and expanding filling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

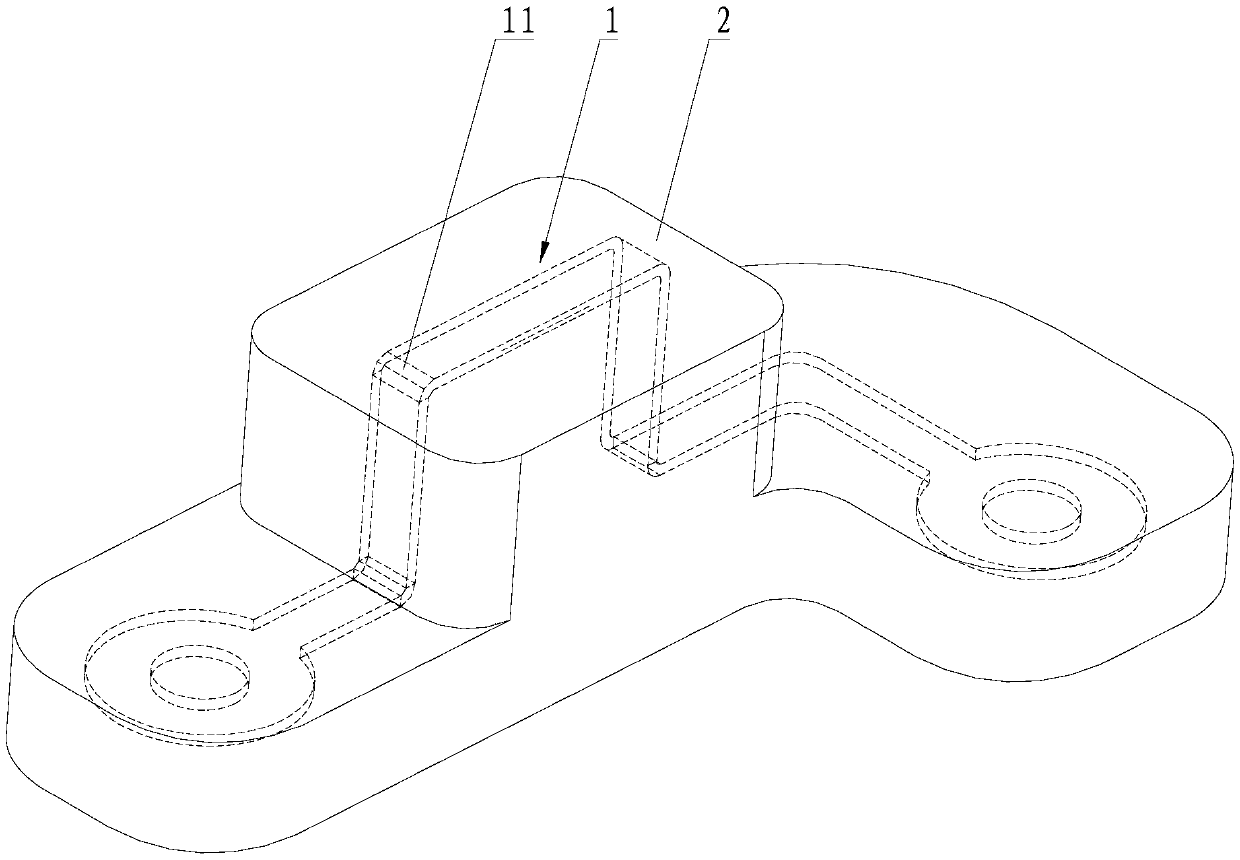

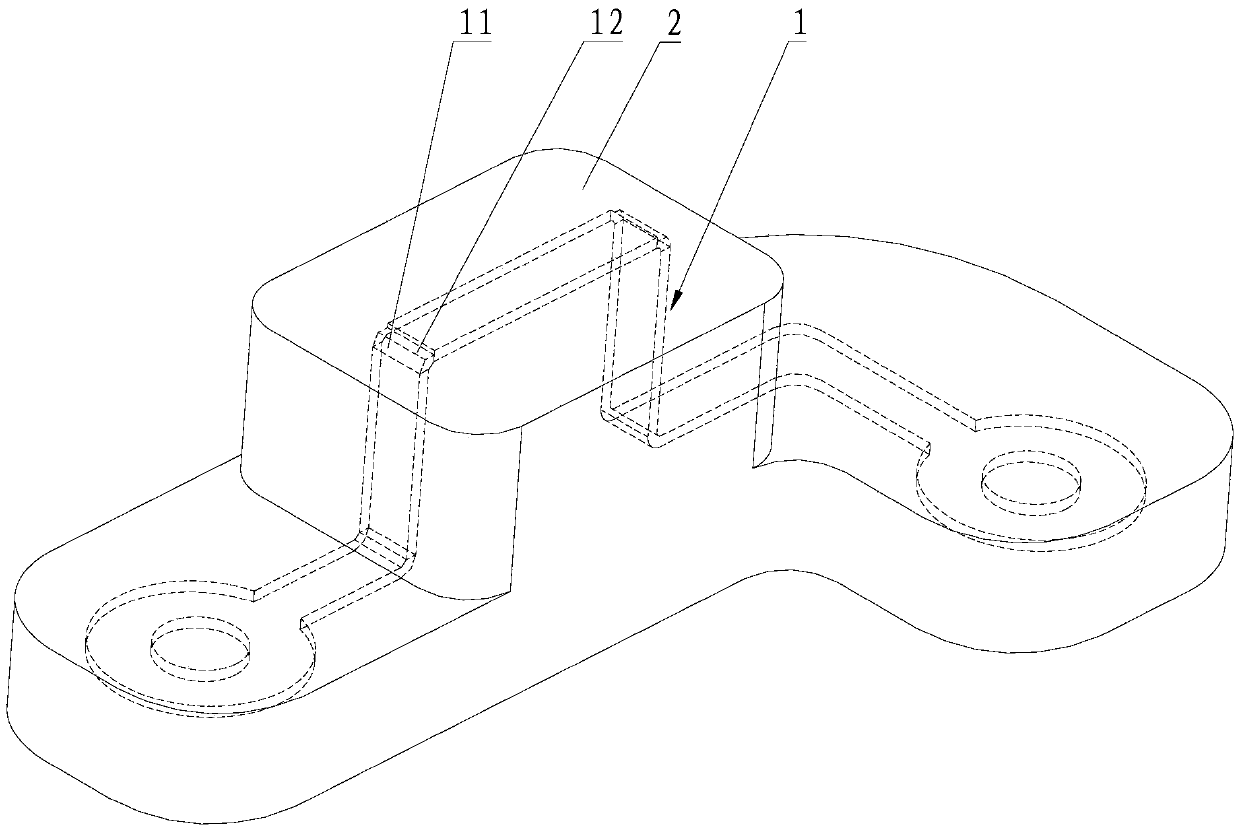

[0035] Please refer to image 3 with Figure 4 , The first embodiment of the present invention is:

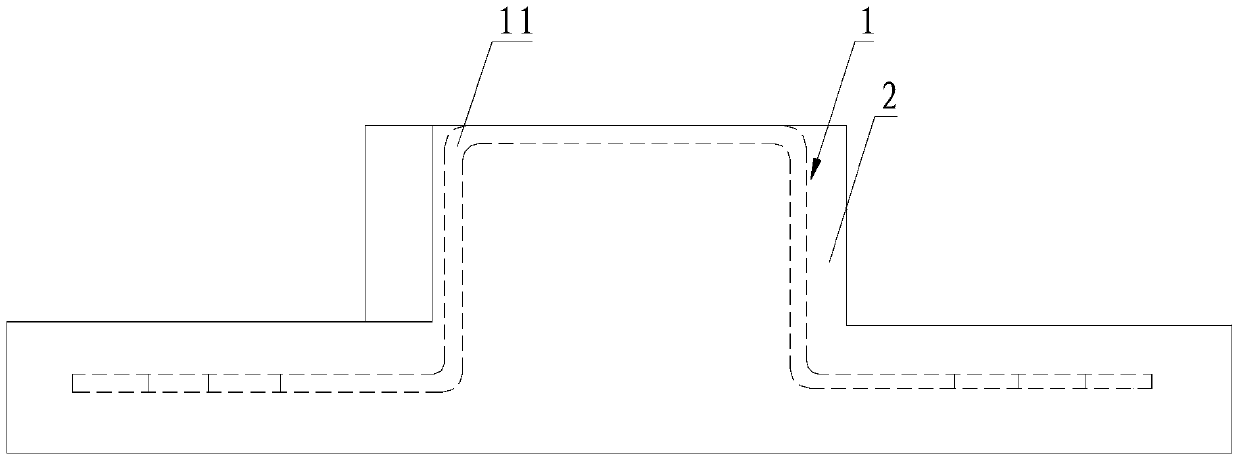

[0036] An insert structure for injection molding includes an insert body 1, a bending portion 11 is provided on the insert body 1, and a step portion 12 is provided on the bending portion 11.

[0037] The bent portion 11 includes a first straight portion and a second straight portion, the first straight portion is connected to the second straight portion, the angle formed by the connection between the first straight portion and the second straight portion is not equal to 180°, and the stepped portion 12 It is arranged at the joint, the number of the stepped portion 12 is two, and the two stepped portions 12 are respectively located at the edge position of the first straight portion and arranged along the width direction of the first straight portion. The provision of two stepped portions 12 can not only increase the filling area of the plastic 2, but also ensure the thickness h2 ...

Embodiment 2

[0042] For an insert structure for injection molding, see Embodiment 1. The difference between the insert structure for injection molding in this embodiment and Embodiment 1 is:

[0043] The depth h1 of the step portion is 0.47-0.49 of the thickness h2 of the bent portion on the insert body 1. When the depth h1 of the step portion is 0.47-0.49 of the thickness h2 of the bending portion, there is still enough space between the insert and the mold to completely fill the plastic 2 to avoid injection defects, and to further increase the insert The strength of the product increases the service life of the product.

[0044] In summary, an insert structure for injection molding provided by the present invention can not only avoid injection molding defects, but also eliminates the need to modify the injection molding mold, which can improve such injection molding defects at a lower cost and increase Improve the production competitiveness of enterprises.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com