Rapid mold changing mechanism of tire

A fast, tire technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of potential safety hazards, low mold replacement efficiency, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

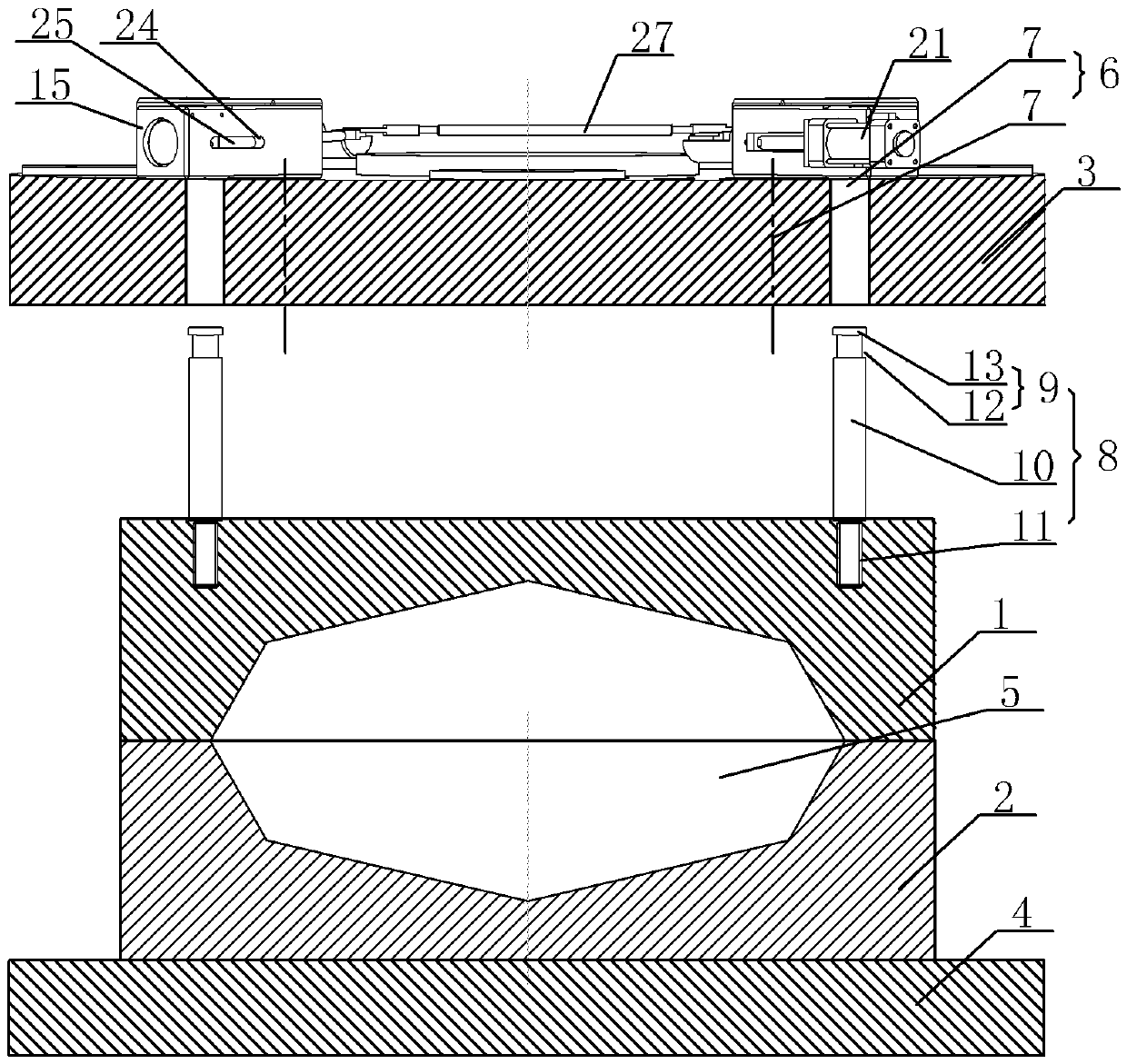

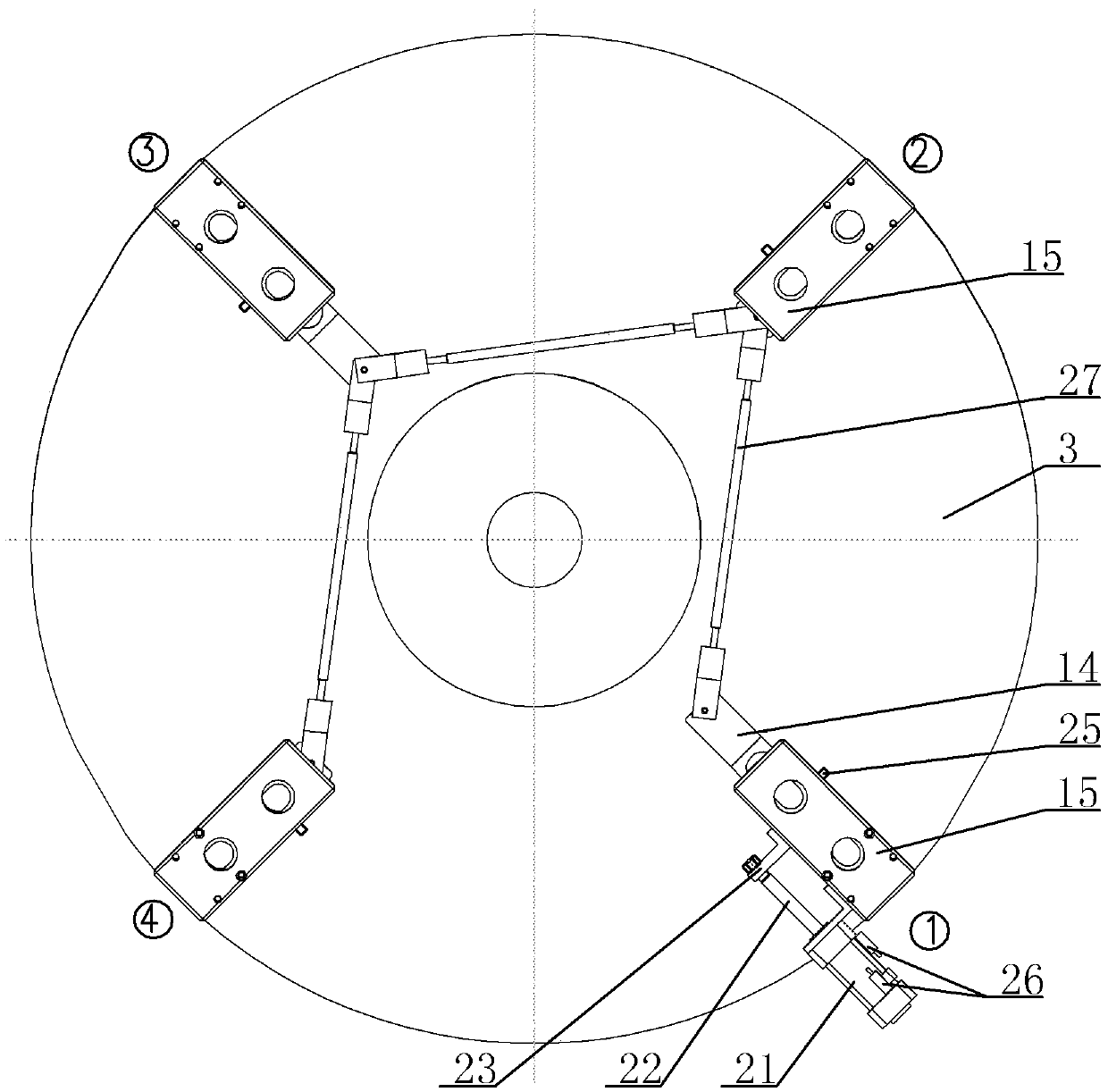

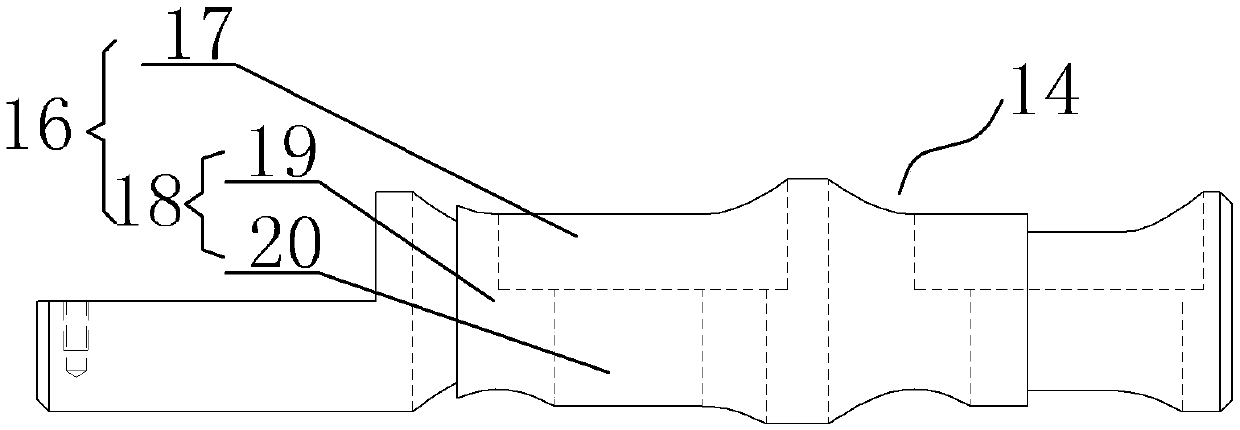

[0020] A kind of quick mold change mechanism of tire, see Figure 1 to Figure 5 : It includes an upper mold 1, a lower mold 2, an upper pallet 3, a lower pallet 4, the upper mold 1 and the lower mold 2 are combined to form a cavity 5, and the upper mold 1 and the lower mold 2 in the working state are located on the upper pallet 3 , between the lower supporting plates 4, the upper supporting plate 3 can move vertically up and down, and the upper supporting plate 3 is provided with N groups of vertically penetrating guide hole groups 6, and each group of guide hole groups 6 includes at least one guide hole 7, wherein N is a natural number ≥ 2. The upper end surface of the upper mold 1 is fixed with N clamping bolts 8. The clamping bolts 8 are exposed on the upper end surface of the upper mold 1. The clamping bolts 8 specifically include the top clamping part 9, the middle The connecting part 10, the bottom fastening thread part 11, the bottom fastening thread part 11 of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com