Metal surface rust removal device

一种金属表面、除锈轮的技术,应用在磨削驱动装置、金属加工设备、磨床等方向,能够解决人工劳动强度降低、无法自动跟踪除锈等问题,达到人工劳动强度降低、消除累积偏差、准确度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

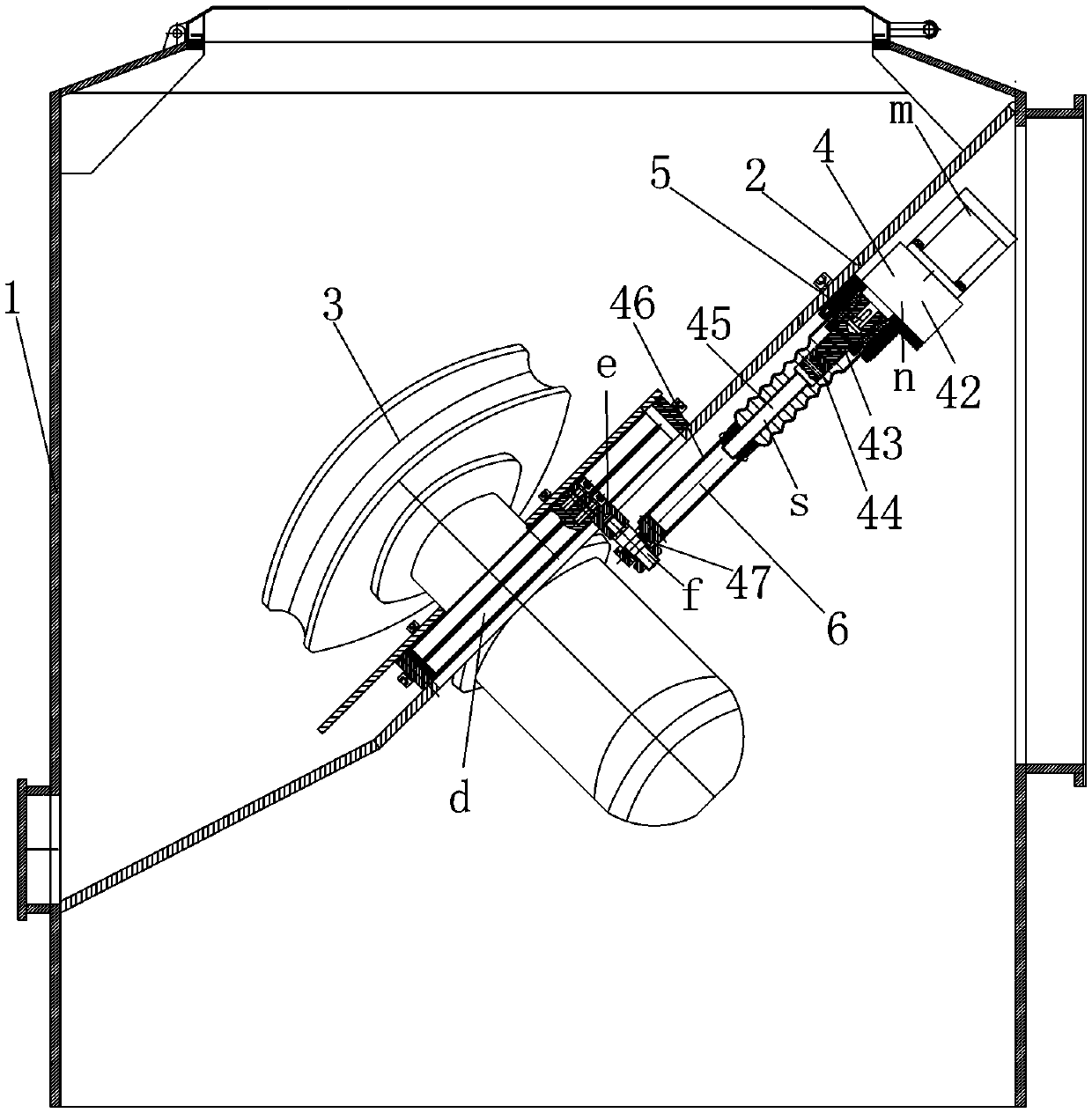

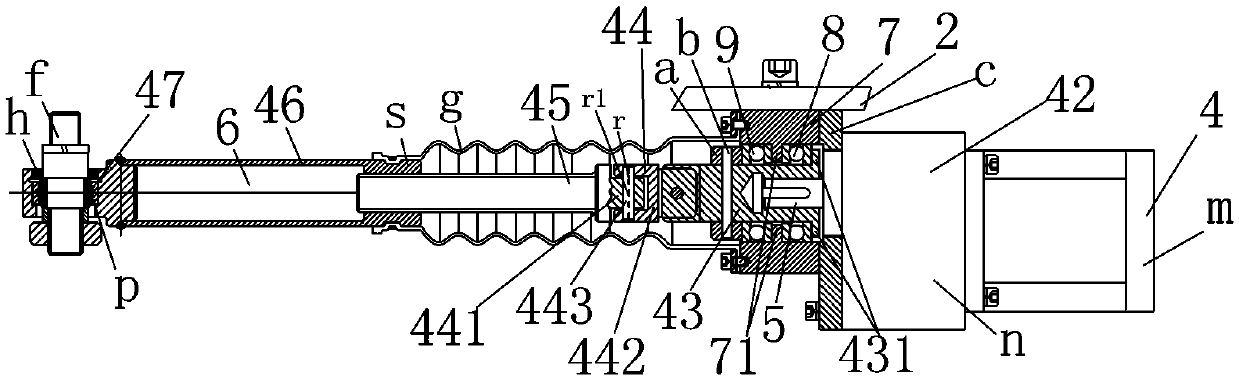

[0013] Such as figure 1 , figure 2 As shown, the first embodiment of the metal surface derusting device provided by the present invention includes a box body 1, an inner sloping plate 2 and a derusting wheel 3 are arranged in the box body 1, and the derusting wheel 3 can be linearly and movably installed Inner inclined plate 2, described inner inclined plate 2 is provided with descaling wheel feeding device 4, and described descaling wheel feeding device 4 comprises motor part m, deceleration part n and feeding part s, here motor part m According to actual needs, AC and DC asynchronous motors, synchronous permanent magnet motors, speed-adjusting motors, stepper motors, and servo motors can be used, and the motor part m, deceleration part n, feed part s and derusting wheel 3 are sequentially driven, that is, That is to say, the motor part m drives the deceleration part n to move, the deceleration part n drives the feed part s to move, the feed part s drives the derusting whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com