Laminar Cooling U-Shape Control System for Hot Rolled Strip

A control system and laminar cooling technology, which is applied in the field of strip steel cooling, can solve problems such as the performance difference between the head and the tail of the strip steel, and achieve the effects of offsetting performance differences, avoiding performance differences, and preventing severe temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

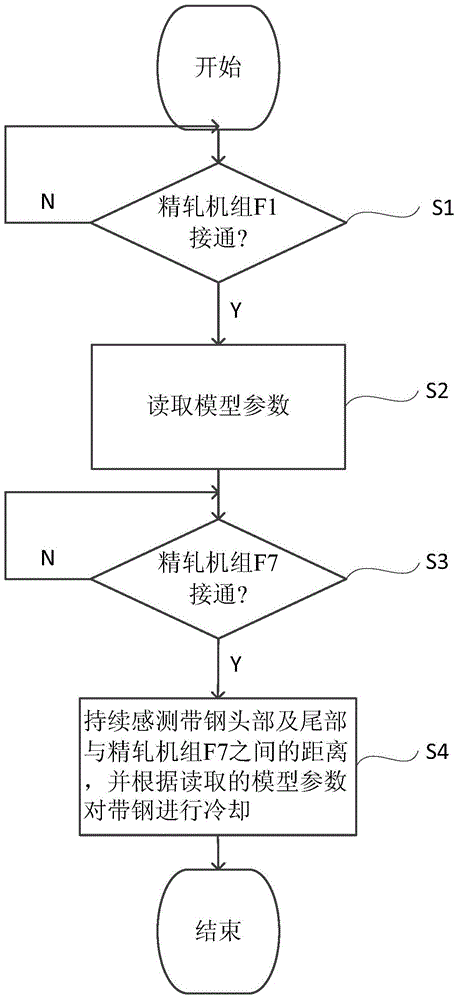

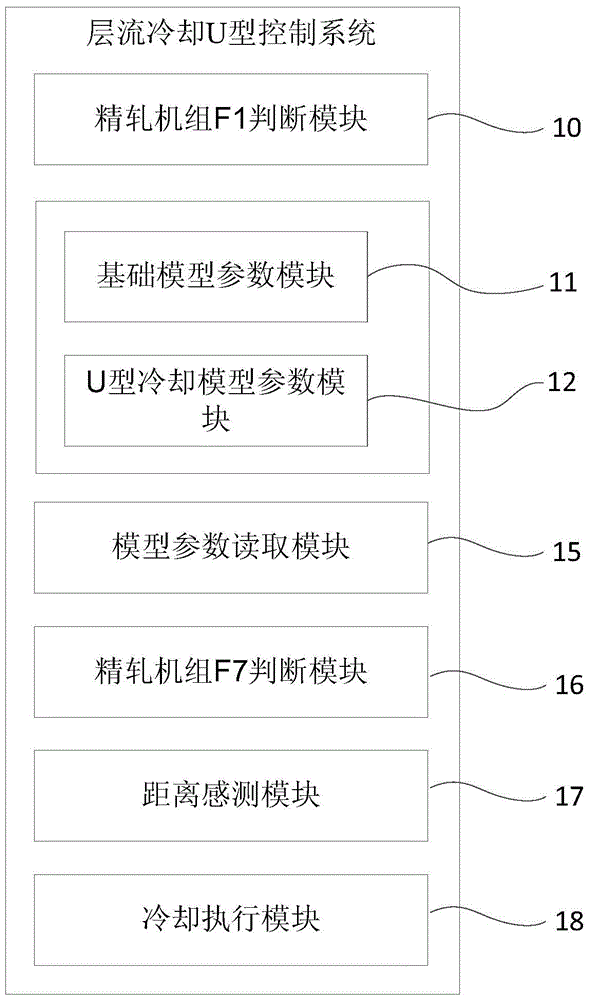

[0041] Specifically, please continue to refer to figure 2 As shown, the present invention is used for the preferred embodiment of the laminar flow cooling U-type control method of hot-rolled strip steel and comprises the following steps:

[0042] Step S1: Judging whether the finishing rolling group F1 is connected. If the finish rolling unit F1 is switched on, it means that the strip is about to enter the finish rolling process, and step S2 is executed. If the finish rolling unit F1 has not been connected, it means that the strip steel has not entered the finish rolling process, and step S1 is continued.

[0043] Step S2: Read model parameters. In order to facilitate equipment transformation and upgrading, in this embodiment, the basic model and the U-shaped cooling model are designed separately. When needing to adopt laminar flow cooling U-type control method of the present invention, read basic model parameter and U-type cooling model parameter simultaneously; When not n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com