water pipe for centrifuge

A centrifuge and water pipe technology, applied in the direction of the centrifuge, etc., can solve the problems of uneven water collection and excessive water discharge from the centrifuge, and achieve the effects of remarkable honey washing effect, small amount of formaldehyde, and reduced process pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

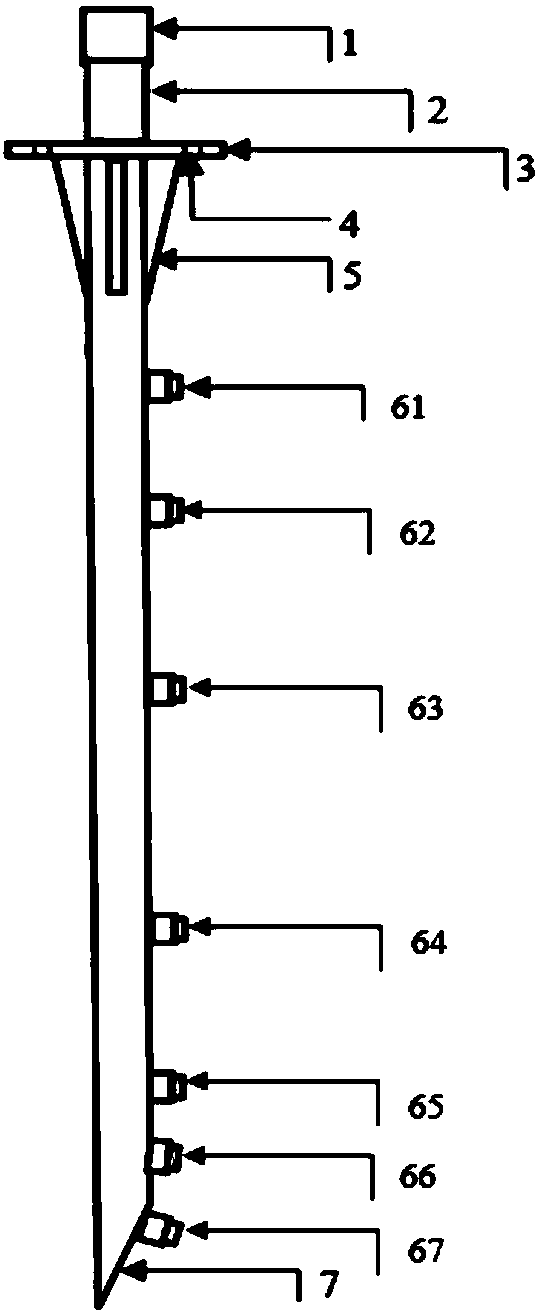

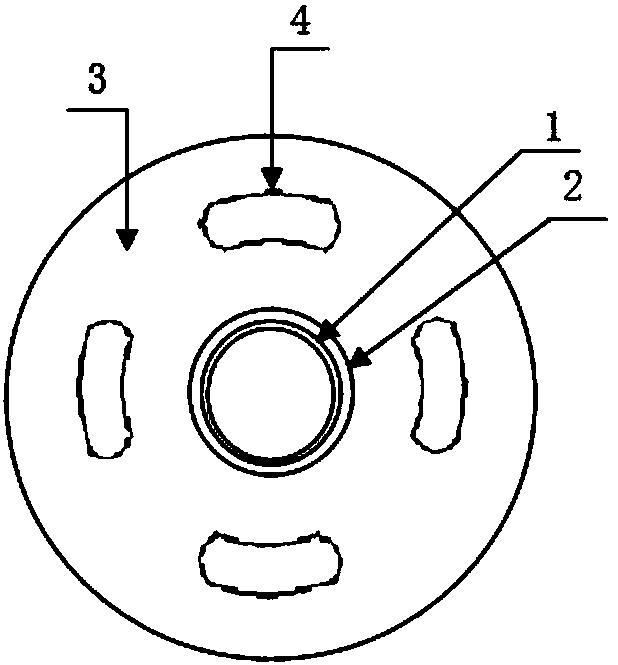

[0018] In the sugar washing process in the sugar factory, the traditional water pipe of the centrifuge is changed to the water pipe designed by the present invention. figure 1 and figure 2 Processed and assembled, the device is fixed on the casing of the centrifuge through the flange. The diameter of its two internal tooth joints is 42 mm, and the other end is a water inlet, which is an interface reserved for connecting the water inlet hose; the length of the water main pipe is 1000 mm. The diameter of the flange is 150 mm, the thickness is 10 mm; the length of the bottom part is 120 mm, and the angle with the horizontal plane is 30 degrees; the four screw holes are arc holes, the hole width is 12 mm, and the length is 60 mm, which is used to adjust the direction of the water pipe And specially made; the length of the triangular steel plate depends on the needs, it is fixed and strengthened to prevent the deformation of the water pipe; there are 7 nozzle joints in total, the...

Embodiment 2

[0020] The water pipe of the centrifuge has a diameter of 42 millimeters in the two internal tooth joints, and the other end is the water inlet, which is the interface reserved for connecting the water inlet hose; the length of the water main pipe is 1000 millimeters. The diameter of the flange is 140 mm, the thickness is 10 mm; the length of the bottom part is 100 mm, and the angle with the horizontal plane is 30 degrees; the four screw holes are arc holes, the hole width is 12 mm, and the length is 60 mm, which is used to adjust the direction of the water pipe And specially made; the length of the triangular steel plate depends on the needs, it is fixed and strengthened to prevent the deformation of the water pipe; there are 7 nozzle joints in total, the diameter of the nozzle joint is 23mm, the length is 13mm, and the distance from top to bottom is 200mm, 70mm, 110mm, 110mm, 110mm, 25mm, 50mm, the nozzle interface set at the bottom is arranged on the bottom of the water pipe...

Embodiment 3

[0022] The water pipe of the centrifuge has a diameter of 42 millimeters in the two internal tooth joints, and the other end is the water inlet, which is the interface reserved for connecting the water inlet hose; the length of the water main pipe is 1000 millimeters. The diameter of the flange is 140 mm, and the thickness is 10 mm; the length of the bottom part is 80 mm, and the angle with the horizontal plane is 30 degrees; the four screw holes are arc holes with a width of 12 mm and a length of 60 mm, which are used to adjust the direction of the water pipe And specially made; the length of the triangular steel plate depends on the needs, it is fixed and strengthened to prevent the deformation of the water pipe; there are 7 nozzle joints in total, the diameter of the nozzle joint is 23mm, the length is 13mm, and the distance from top to bottom is 200mm, 80 mm, 120 mm, 120 mm, 120 mm, 25 mm, 60 mm, the nozzle interface set at the bottom is arranged on the bottom of the water ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap