Discharge port size detecting system of jaw crusher

A jaw crusher and detection system technology, applied in measurement devices, grain processing, instruments, etc., can solve problems such as inaccuracy and lag, and achieve the effect of reducing uncertainty, ensuring production technology, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

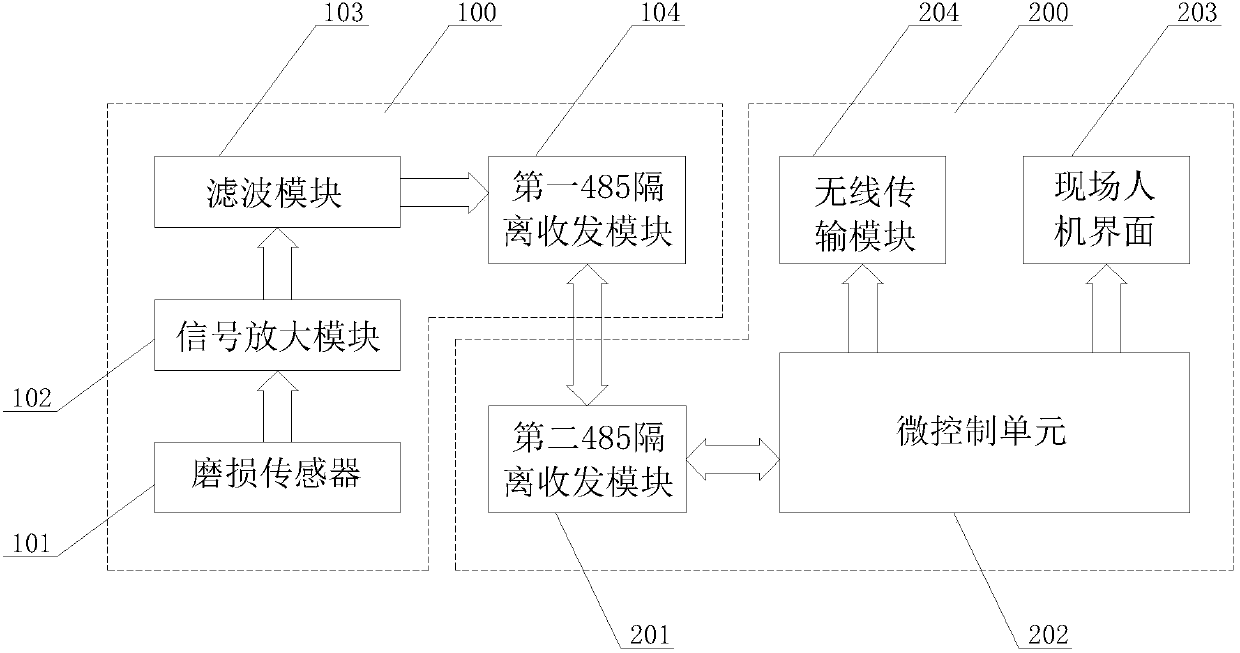

[0025] Such as figure 2 As shown, a jaw crusher discharge opening size detection system includes a front sensor subsystem 100 and a control and transmission subsystem 200 .

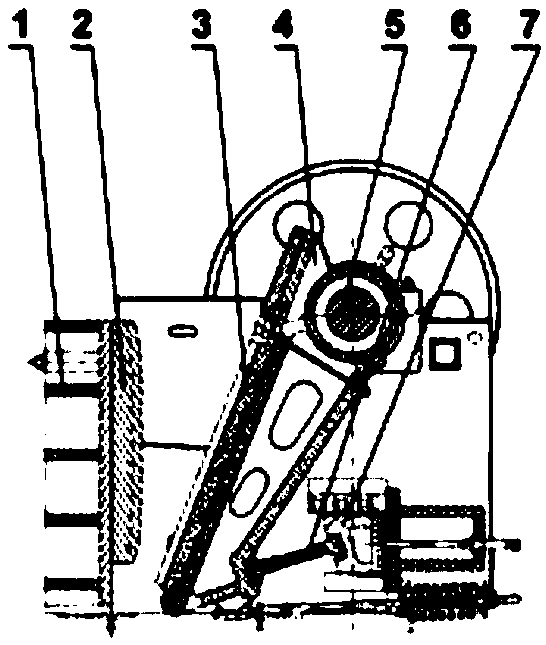

[0026] The front-end sensor subsystem 100 specifically includes a wear sensor 101 , a signal amplification module 102 , a filter module 103 and a first 485 isolation transceiver module 104 . In the present invention, there are two wear sensors 101, the shape of which is a cylinder, and a pair of wiring grooves are symmetrically opened on the side wall of the cylinder, and a number of through holes at equal intervals are opened in the wiring grooves, and the through holes are pierced with control valves. The wear detection circuit connected to the detection circuit. Two wear sensors 101 are respectively built in the lower edge positions of the fixed jaw plate 2 and the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com