An oil-type steamed bun machine and steamed bun method

A steamed bun machine, oil-type technology, applied in oil/fat roasting, roasting, roasting workshops, etc., can solve the problems of low moisture content and inability to make buns, and achieve the effect of saving processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

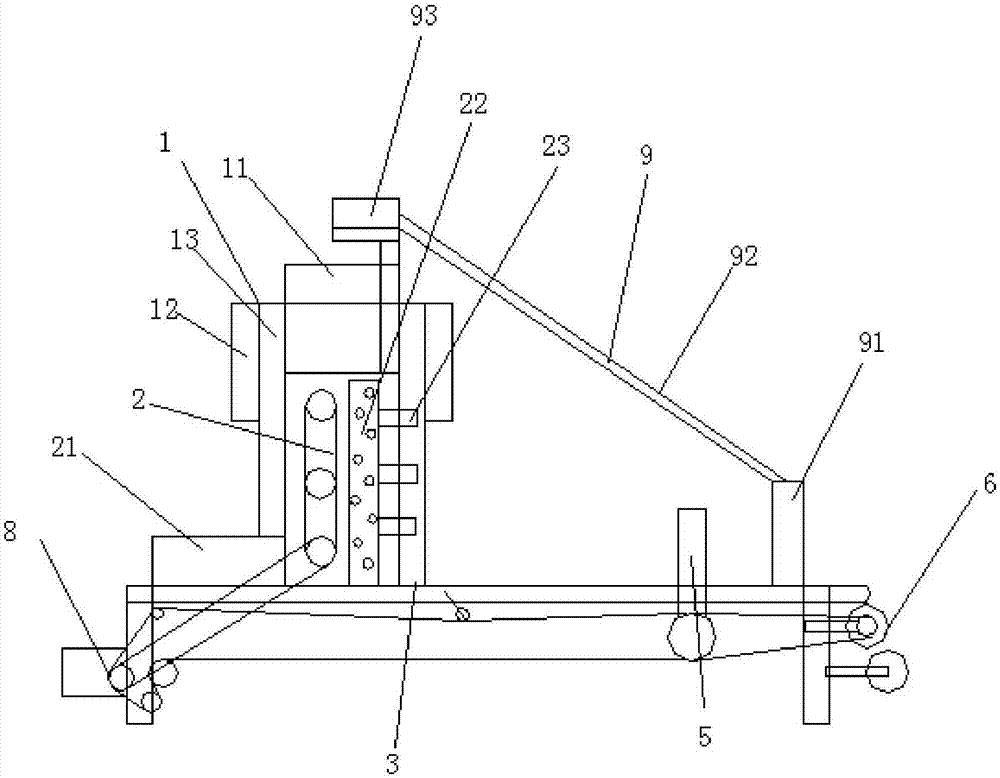

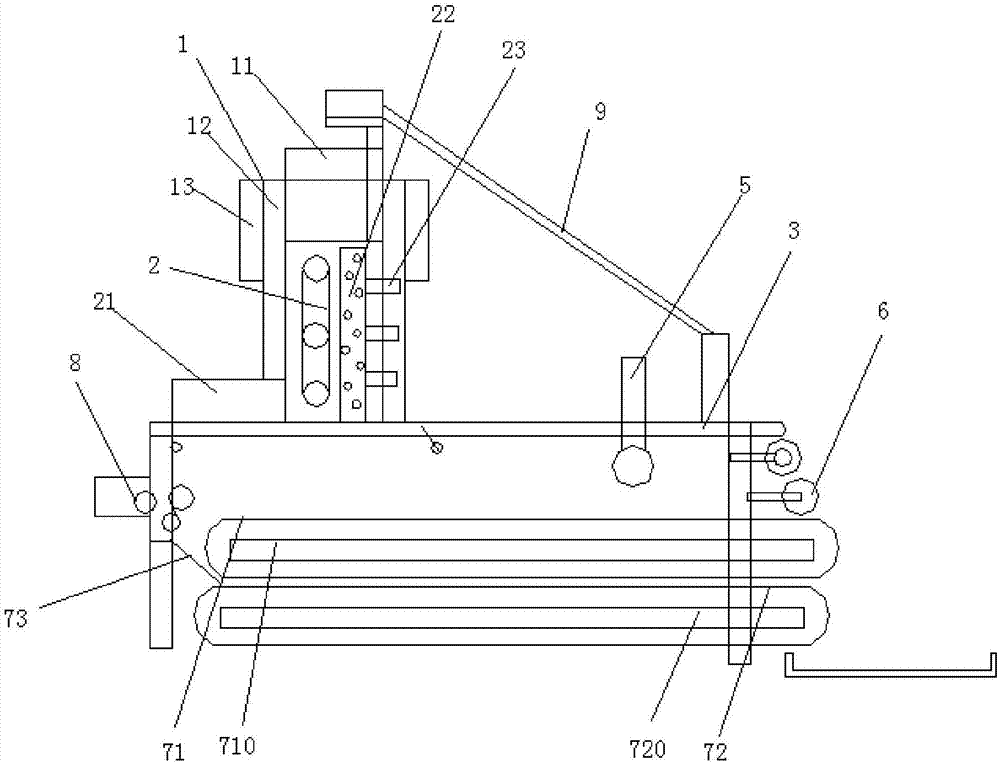

[0032] A kind of oil-type steamed bun machine of present embodiment, as Figure 1-2 As shown, a kind of oil-type steamed bun machine comprises a workbench, a feed port 11, a pair of more than a pair of dough rolls 2, an oiler 1, the dough rolls 2, and the workbench is provided with dough pieces The forming frame 22, the first conveyor belt 3, the metal heating roller group 6, the first metal conveyor belt 71, and the second metal conveyor belt 72; The bearing assembly is installed on the dough sheet forming frame 22, so that the dough sheet roller 2 is rotationally connected with the dough sheet forming frame 22, and the dough sheet roller 2 is positioned below the feed port 11 simultaneously; the bearing assembly and the dough sheet The forming frame 22 is slidingly connected, and the dough sheet forming frame 22 is provided with an adjusting bolt 23, and one end of the adjusting bolt 23 is rotationally connected with the bearing assembly, and the bearing assembly is adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com