Corn threshing mechanism

A corn threshing and threshing drum technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of scratches, low efficiency, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

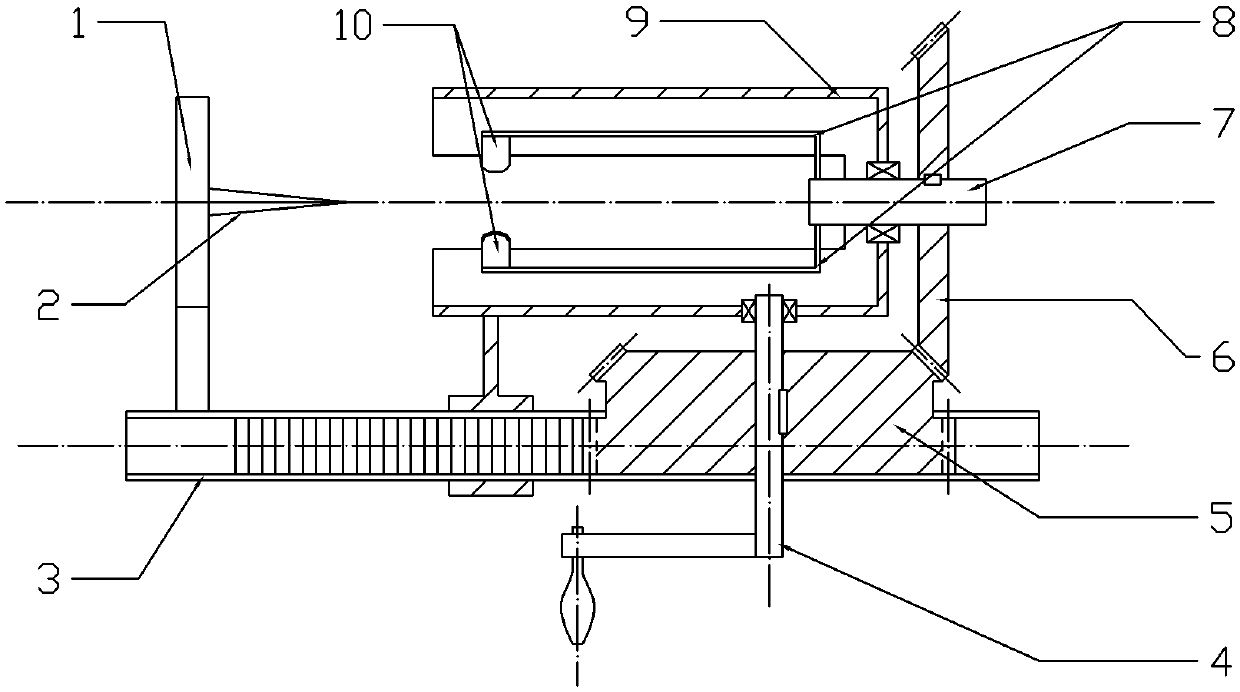

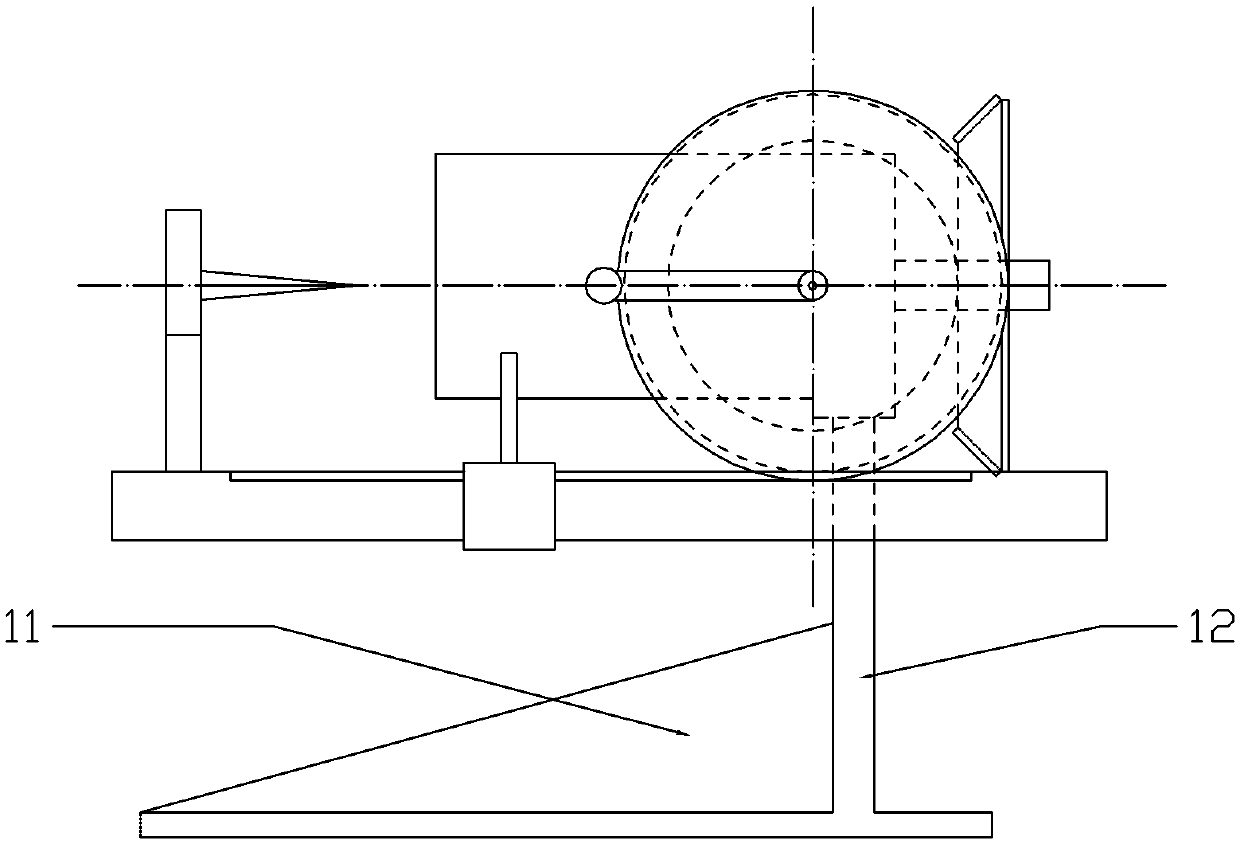

[0018] A kind of corn threshing mechanism of embodiment is basically as attached figure 1 , figure 2 shown.

[0019] A corn threshing mechanism in this embodiment includes a bracket 12, a threshing cylinder 9, a rack 3, a push plate 1, a fixed cone 2, a double gear 5, a hand lever 4, a bevel gear 6 and an L-shaped bracket 8. The threshing cylinder 9 is a hollow cylinder, and its peripheral wall is welded on the top of the bracket 12 and arranged horizontally. The left side of the threshing cylinder 9 is an opening; Go through the sleeve and slide it into it; the left end of the rack 3 is welded with a push plate 1, and the side of the push plate 1 facing the threshing cylinder 9 is welded with a fixed cone 2 pointing to the threshing cylinder 9 and coaxial with it , the cross-section of the fixed cone 2 is cross-shaped; the left end of the rack 3 is meshed with the straight tooth part of the double gear 5, and the shaft 7 on the hand lever 4 is keyed to the gear of the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com