Skew stacked rotor press-fitting fixture

A technology of rotor and fixture, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of complex structure, complicated operation, troublesome mold removal, etc., and achieve the effects of convenient mold removal, good assembly accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

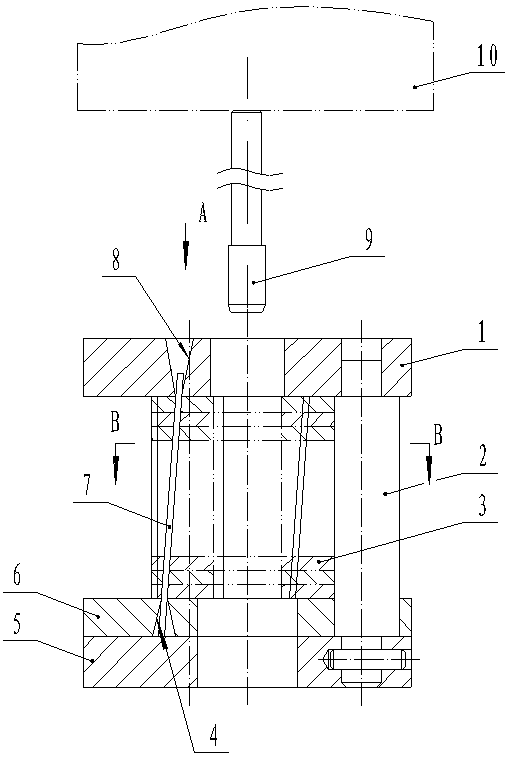

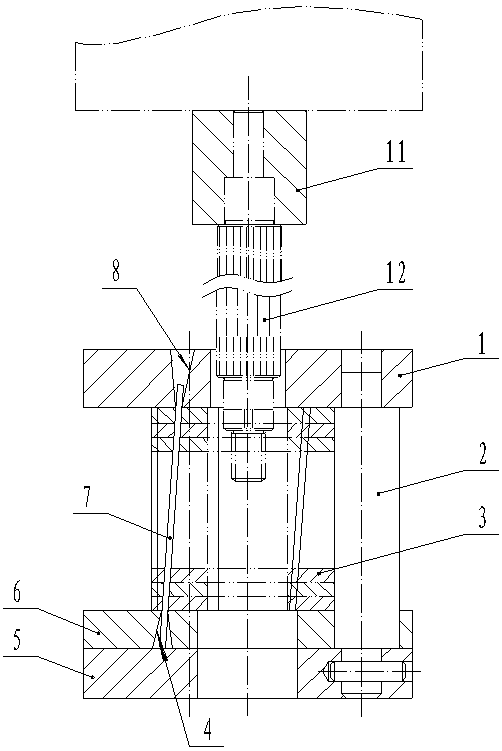

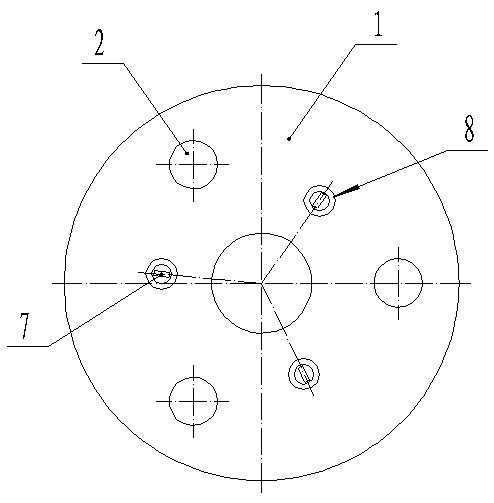

[0015] as attached Figure 1~6 As shown, the backing plate 6 is fixed on the base 5, and there are through holes on the backing plate 6 and the base 5; three positioning columns 2 evenly distributed with the center of the backing plate 6 as the center of the circle are fixed on the base 5, and the pressing plate 1 is positioned on the positioning column 2 superior. The pressure plate 1 has three first speaker holes 8 with upper and lower dimensions uniformly distributed around the center, and the backing plate 6 has three upper and lower second speakers with the center as the center of the circle. Hole 4, the first horn hole 8 and the corresponding second horn hole 4 are staggered clockwise or counterclockwise by 15º8´ with the center as the center; the pin 7 is inserted in the corresponding first horn hole 8 and the second horn hole 4 Between, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com