Multi-purpose assembly fixture for skewed laminated stator core

A stator core and assembly fixture technology, which is applied in the manufacture of stator/rotor bodies, electromechanical devices, and motor generators. It can solve the problems of inaccurate torsion angle of the chute, high labor intensity, and cumbersome operation, and achieve skew Precise angle, extended scope of application, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

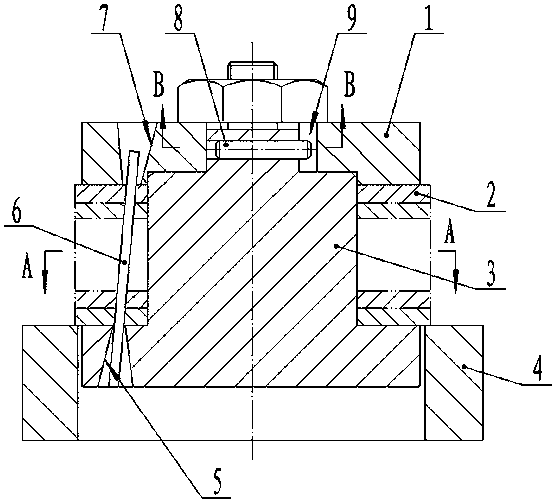

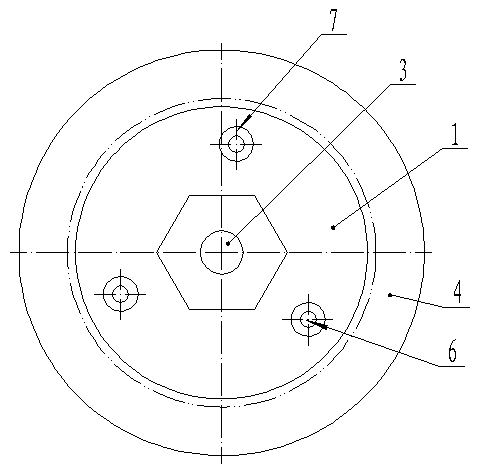

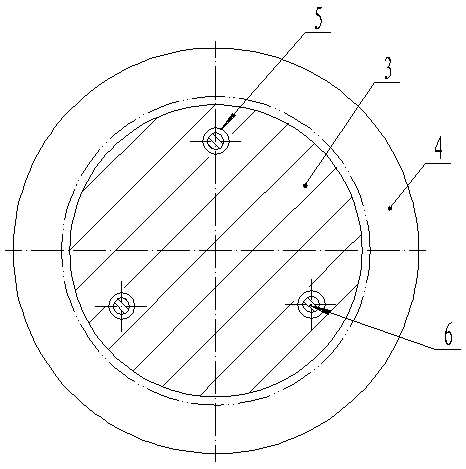

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] as attached Figure 1~6 As shown, the pressure plate 1 is set on the stepped positioning mandrel 3 through the female stop, and the pressure plate 1 has three upper and lower first horn holes 7 evenly distributed with the axis of the positioning mandrel 3 as the center of the circle. On the mandrel 3 there are three second horn holes 5 that are evenly distributed with the axis as the center of the circle; the first horn hole 7 and the corresponding second horn hole 5 are staggered with the axis as the center of the circle. Angle, the pin 6 is inserted between the corresponding first horn hole 7 and the second horn hole 5 . The bolt 6 is clearance fit with the second horn hole 5 and the first horn hole 7 .

[0016] In order to facilitate the clamping of the laminated stator core sheets 2, an inner hole (not shown in the figure) is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com