A compressed gas load switch for high-voltage gas-insulated ring main unit

A high-voltage gas and load switch technology, applied in high-voltage/high-current switches, high-voltage air circuit breakers, electric switches, etc., can solve problems such as uneven distribution of electric field, difficulty in ensuring concentricity of moving contacts, and complicated assembly process, etc., to achieve Improve reliability and stability, good reliable insulation, good effect of electric field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

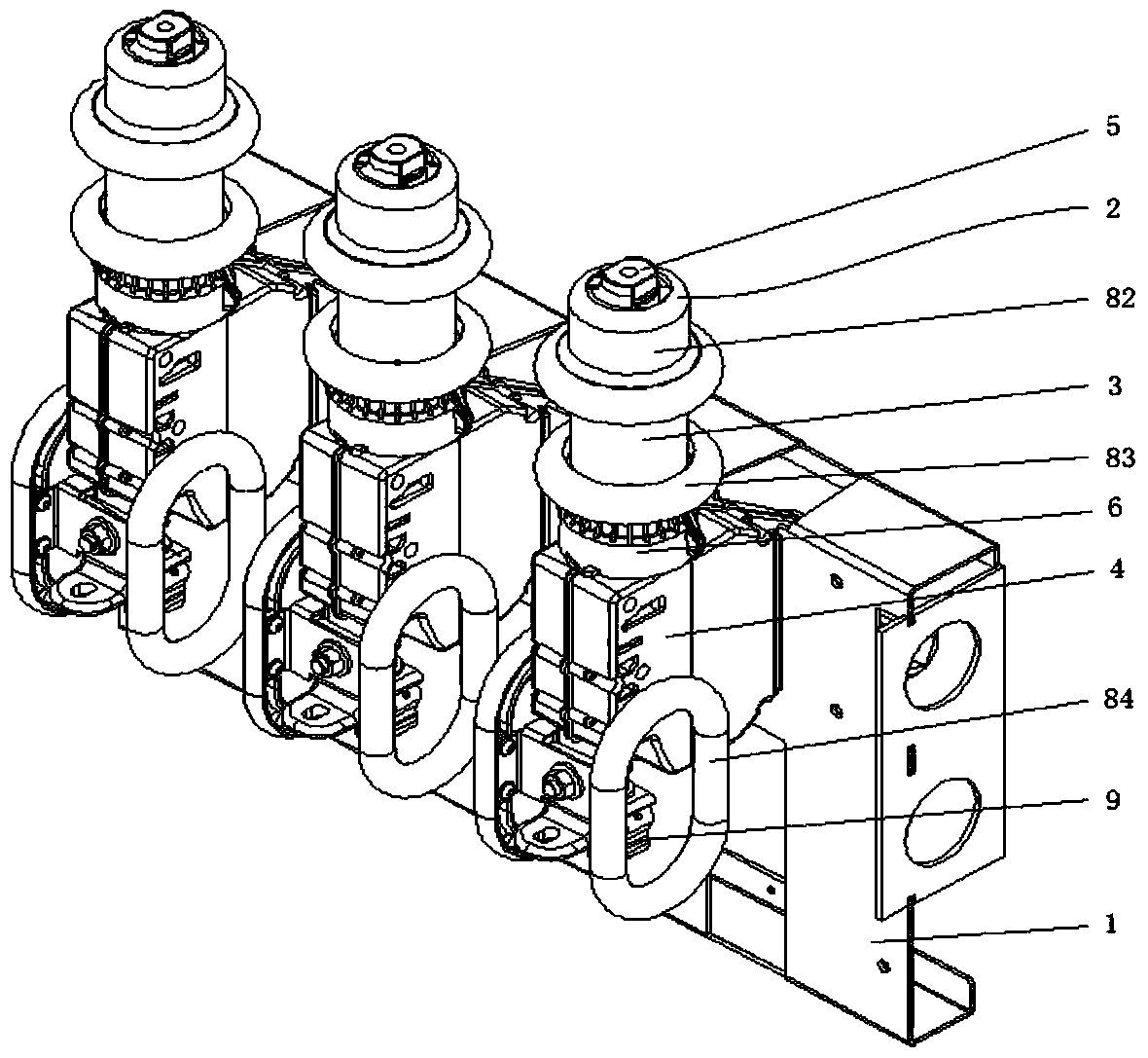

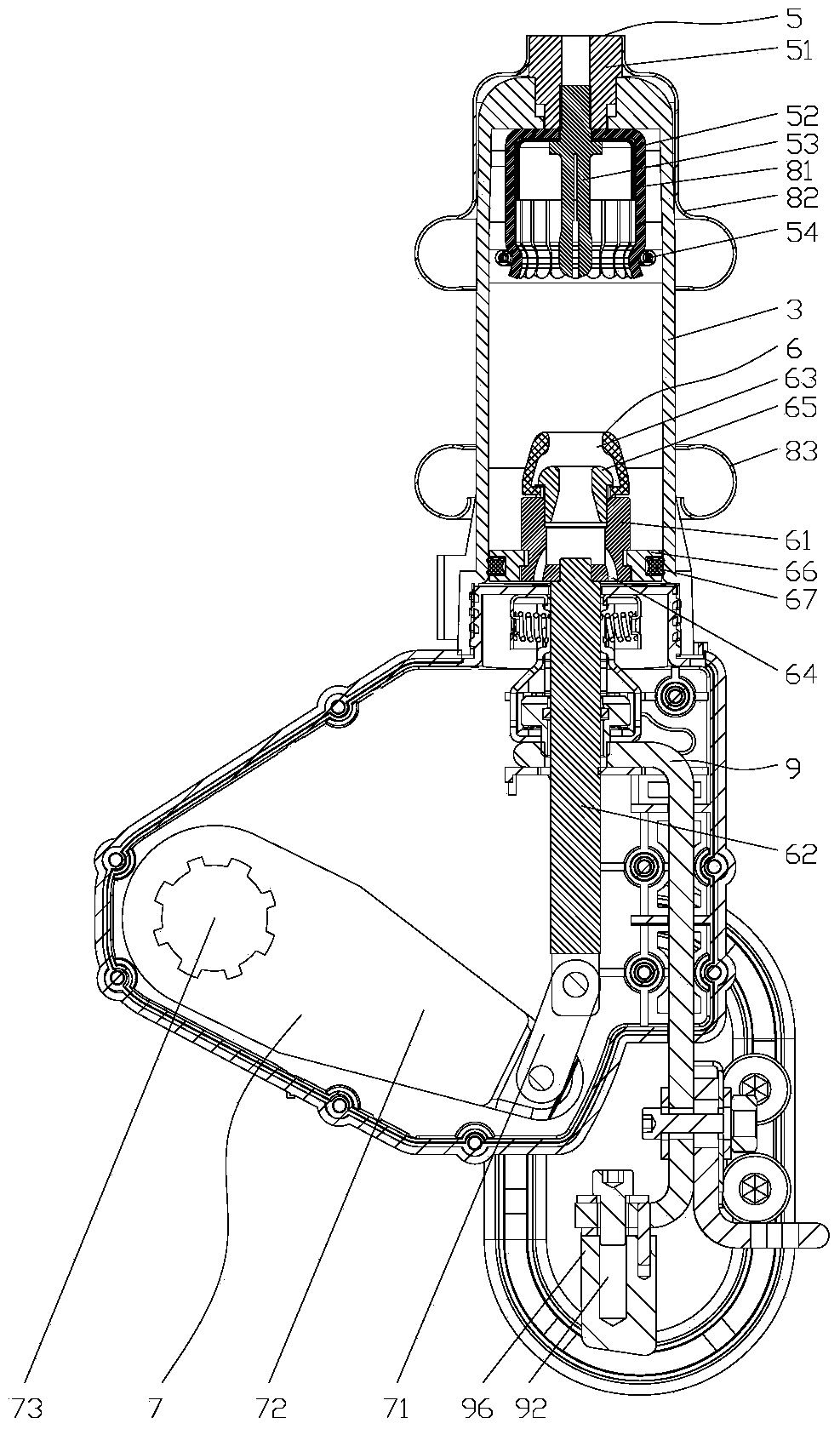

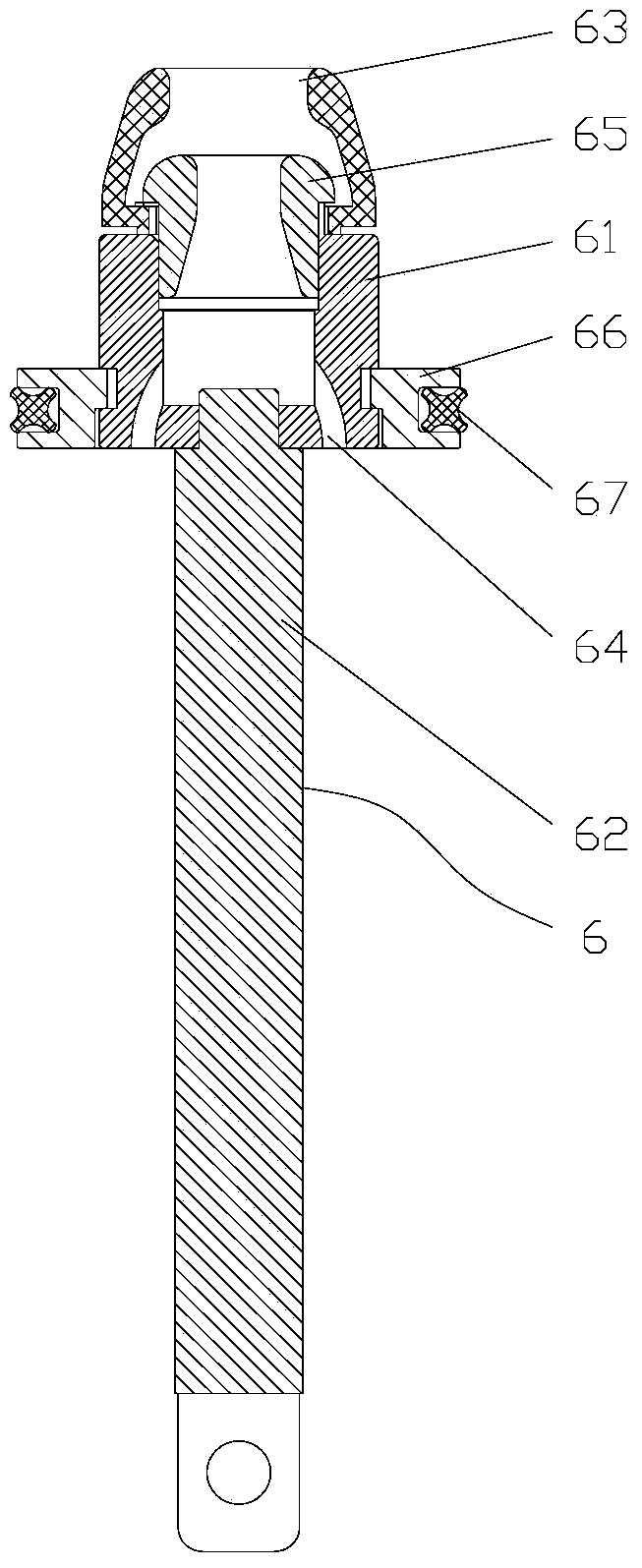

[0020] Such as Figure 1-6 As shown in one, the present invention includes a bracket 1, on which three switch units 2 are arranged, and the three switch units 2 form a three-phase integrated structure with the bracket 1, and the switch unit 2 includes an insulating cylinder 3, an insulating contact box 4. The static contact assembly 5, the moving contact assembly 6 and the crank arm assembly 7, the static contact assembly 5 and the moving contact assembly 6 are respectively arranged on the upper end and the lower end of the insulating cylinder 3, and the moving contact assembly 6 and the inner wall of the insulating cylinder 3 Contact to form an arc extinguishing chamber, the static contact assembly 5 includes a static contact seat 51 and a plum blossom static contact 52 arranged on the upper end of the insulating cylinder 3, and a plum blossom static contact 52 is provided with a pressure equalizing sleeve 81 and an arc strike needle 53 , one end of the arc striking needle 53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com