A pipe body restraint device in pressure relief of high-pressure metal gas pipeline pressure blasting test

A blasting test and restraint device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of casualties on the ground, damage to buildings and facilities, economic losses and environmental pollution, etc., and achieve the effect of controllable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

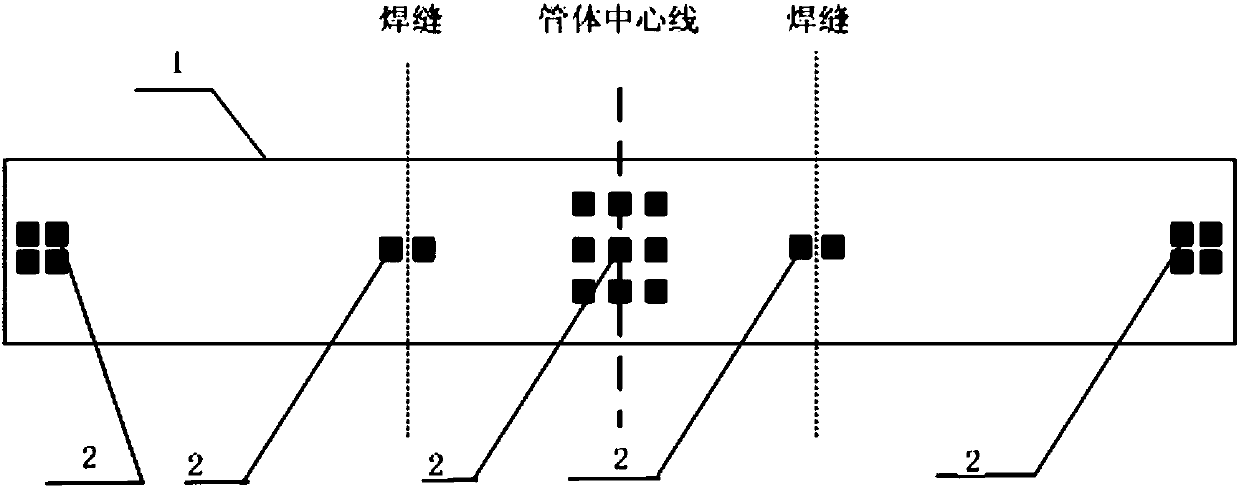

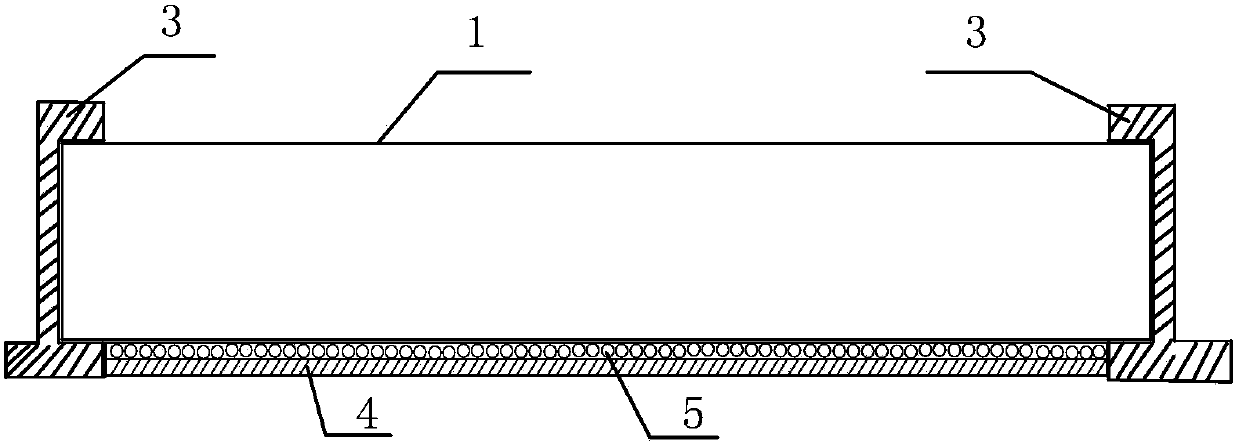

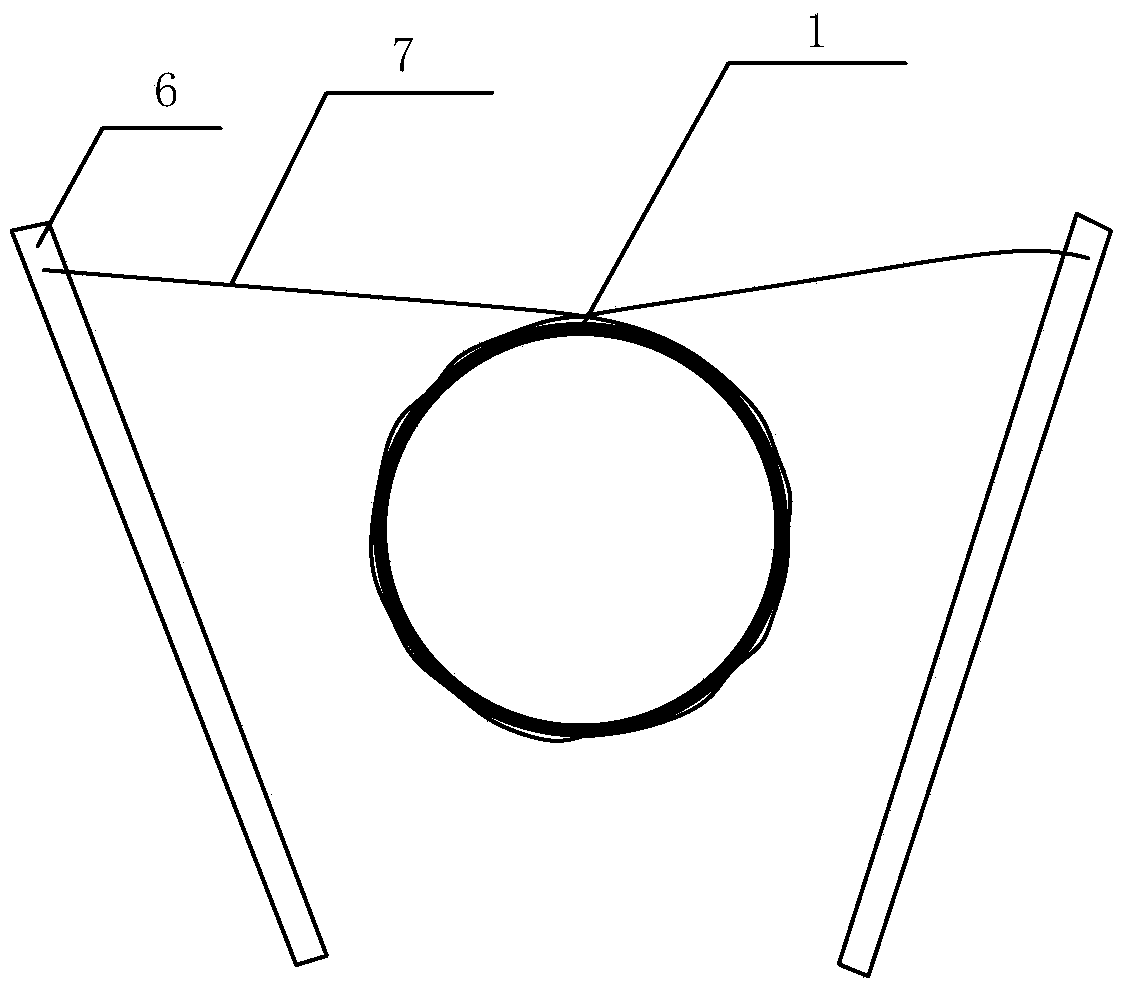

[0014] Such as Figure 1 to Figure 3 As shown, a high-pressure metal gas pipeline 1 of the present invention is a pipe restraint device in the air pressure blasting test pressure relief, including a fixed platform, the fixed platform is located on the foundation, and the fixed platform is provided with a pipe groove for accommodating the high-pressure metal gas pipeline 1, Anchors 3 are installed at both ends of the pipe groove, and several groups of friction piles are arranged on the fixed platform. Each group of friction piles includes two friction pile units 6, and the fixed flexible flexible pipe 1 is wound on the friction pile units 6 to fix the high-pressure metal gas pipeline 1. The steel cable 7 is provided with a supporting layer below the pipe groove, and a plurality of fixed piles 2 are arranged on the supporting layer, and the top of the fixed pile 2 is flush with the bottom end of the pipe groove.

[0015] Such as figure 1 As shown, nine fixed piles 2 are evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com