Wide-range pulse force calibration device

A calibration device and pulse force technology, applied in measuring devices, force/torque/power measuring instrument calibration/testing, fluid pressure measurement, etc., can solve problems such as low accuracy, complex structure, small upper limit of calibration range, etc., to achieve The effect of high accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

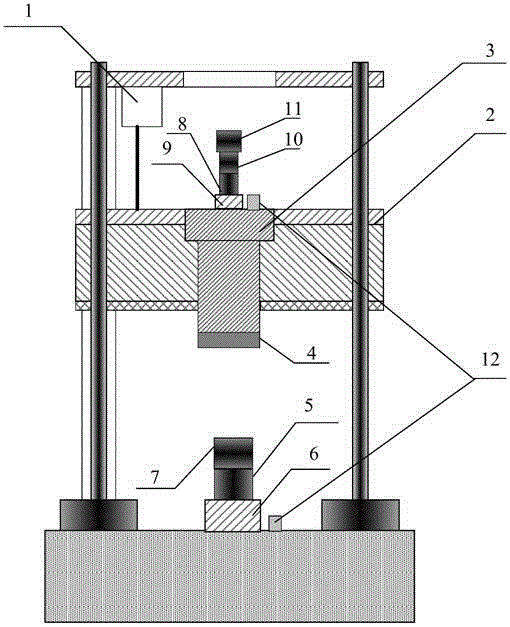

[0045] The structure of a wide-range pulse force calibration device is as follows: figure 1As shown, it mainly includes device base 1, guide rail 2, buffer mechanism 3, drop hammer lifting and releasing mechanism 4, hammer body righting mechanism 5, sledgehammer body 6 sets and cushion layer 7 sets, large-range reference dynamic force Sensor 8 and anvil 9, small range reference dynamic force sensor 11 and installation anvil 12, small hammer body 14 sets, high precision standard accelerometer 15. Install the large-range reference dynamic force sensor 8 on the device base 1 through the anvil 9, with the sensitive side facing up, and the sensitive side of the large-range force sensor 10 to be calibrated faces down and is fixedly installed face-to-face with the large-range reference dynamic force sensor 8; The reference dynamic force sensor 11 is installed in the middle of the upper end face of the sledgehammer body 6 through the installation anvil 12, with the sensitive side faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com