Device for measuring radial run-out of main shaft

A technology of radial runout and spindle, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of evaluation, increase of errors, and large errors that affect the performance of CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

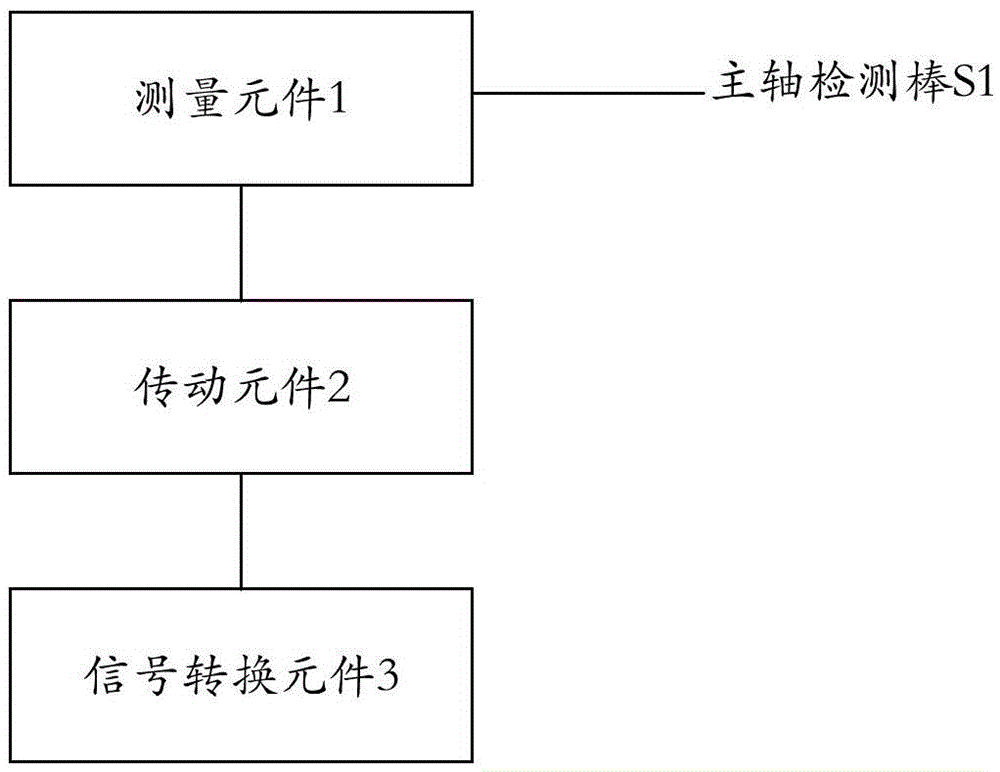

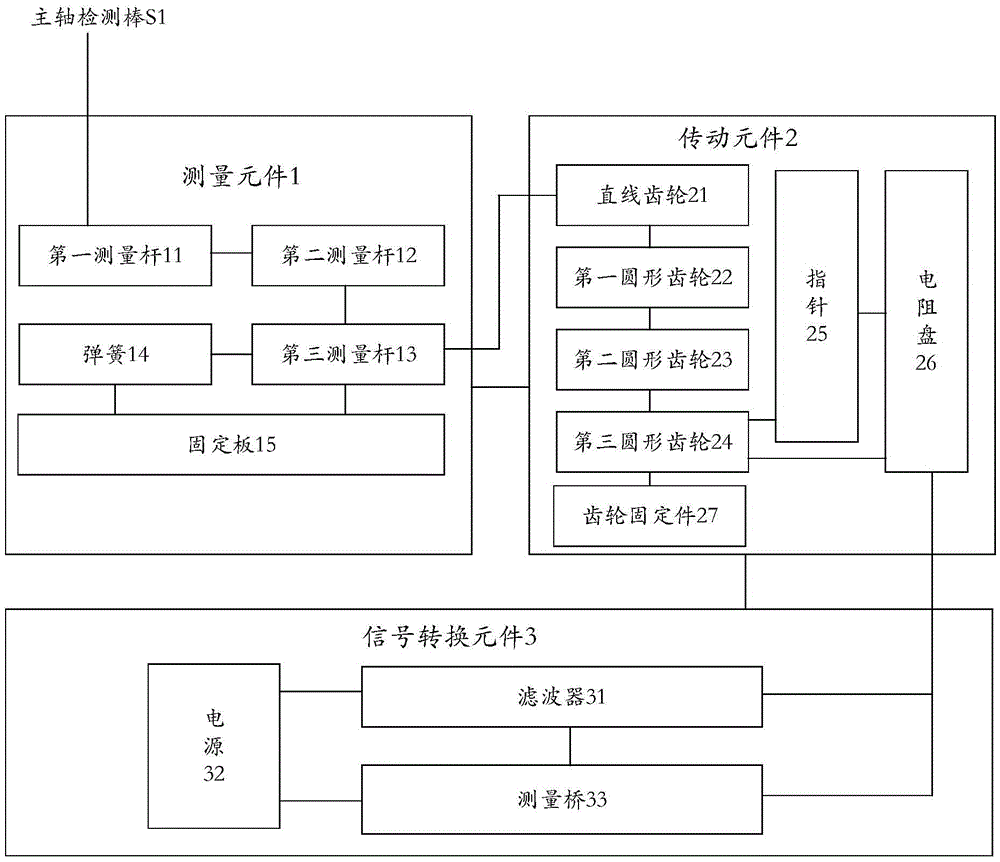

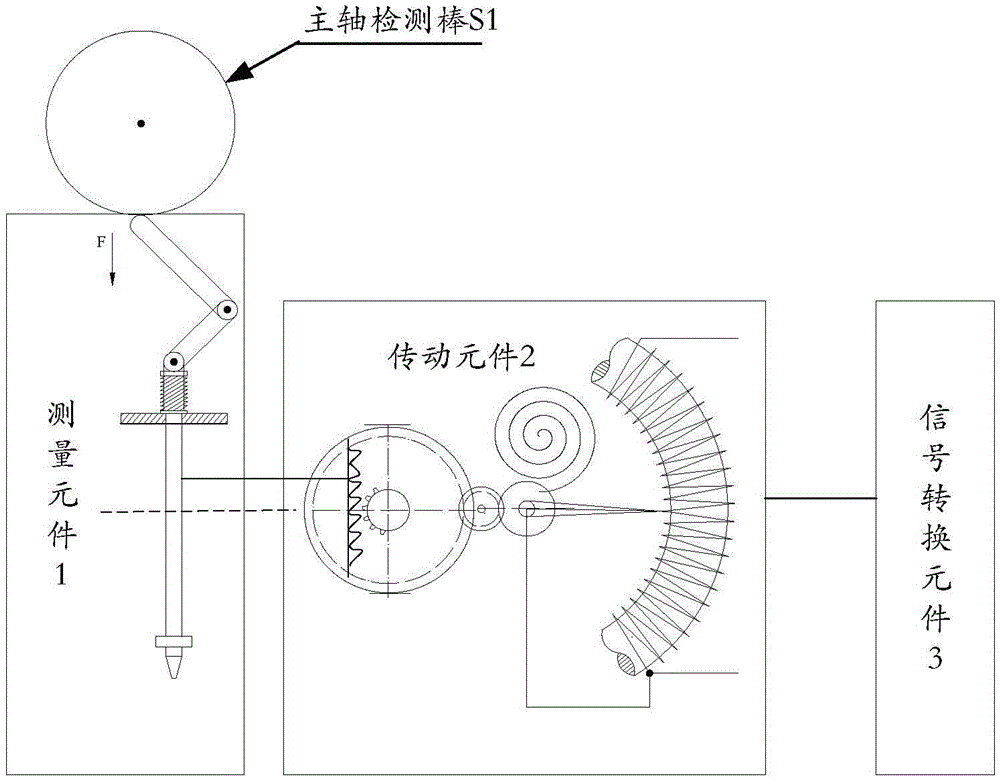

[0059] see Figure 1A , an embodiment of the present invention provides a device for measuring the radial runout of a spindle. The device includes: a measuring element 1, a transmission element 2 and a signal conversion element 3;

[0060] The measuring element 1 is respectively connected with the spindle detection rod S1 and the transmission element 2, detects the radial displacement of the spindle, and transmits the radial displacement signal of the spindle to the transmission element 2 to drive the transmission element 2;

[0061] The signal conversion element 3 is connected with the transmission element 2, converts the radial displacement signal of the main shaft transmitted by the transmission element, and outputs the radial runout signal of the main shaft in the form of an electric signal.

[0062] The above-mentioned spindle detection rod S1 is connected to the spindle of the CNC machine tool, and before the radial runout of the spindle is measured, the spindle detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com