Lithium ion battery pole piece drying device

A lithium-ion battery and drying device technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as pinholes, large footprint, cracks, etc., to facilitate assembly and movement, and improve production Efficiency, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

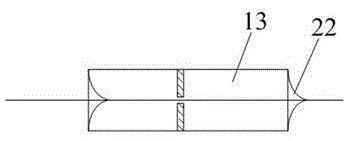

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a cabinet body 1, an unwinding support 101 is provided on the upper front end of the cabinet body 1, an unwinding shaft 102 is provided on the unwinding support 101, and a pole piece base belt is set on the unwinding shaft; Roller; the input roller 5 is provided at the entrance of the outer front pole piece of the cabinet 1; the cabinet 1 is divided into heating chamber I2, heating chamber II3 and heating chamber III4 in turn; the heating chamber I2 is provided with longitudinally staggered The turning roller I6, which is located at the upper end of the heating chamber I2, and the turning roller I6 at the lower end of the adjacent heating chamber I2 form a group of infrared drying groups, and the adjacent infrared drying groups are provided with longitudinal infrared heaters 7 ; The upper end of the heating chamber I2 is provided with a first transmission port 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com