Torque-transferable self-sealing drilling tool lifting device

A self-sealing and drilling tool technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of lack of connection and sealing, complicated operation, and long auxiliary operation time, and achieves simple structure, convenient operation, and reduced Effect of Auxiliary Working Hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

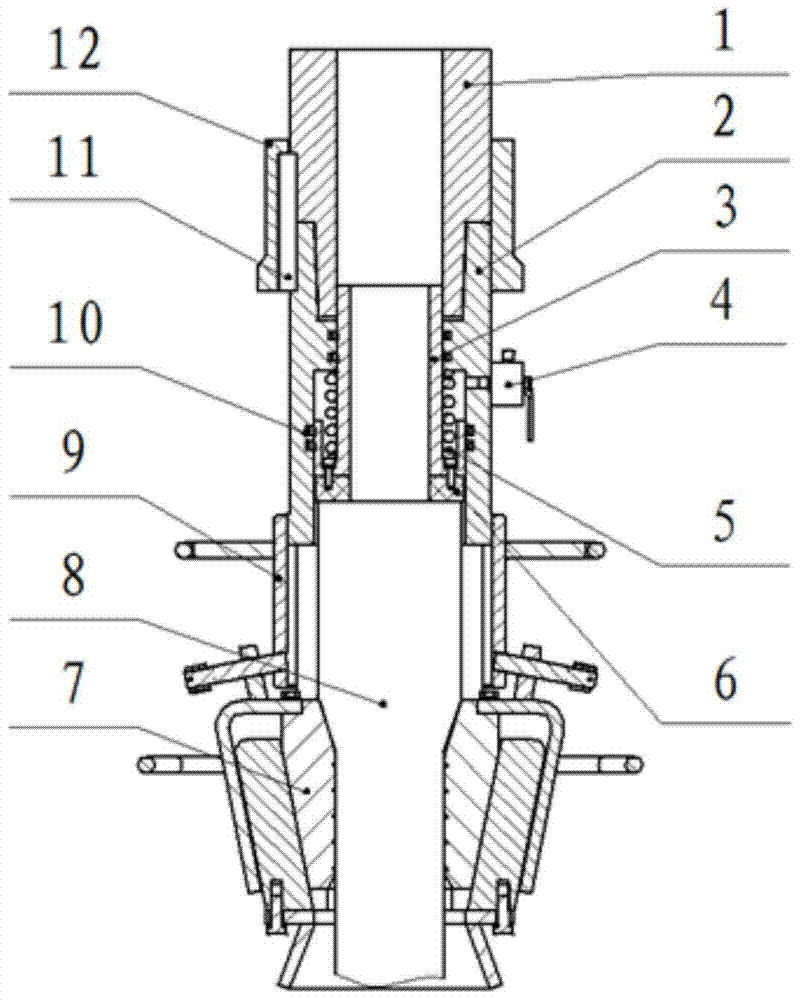

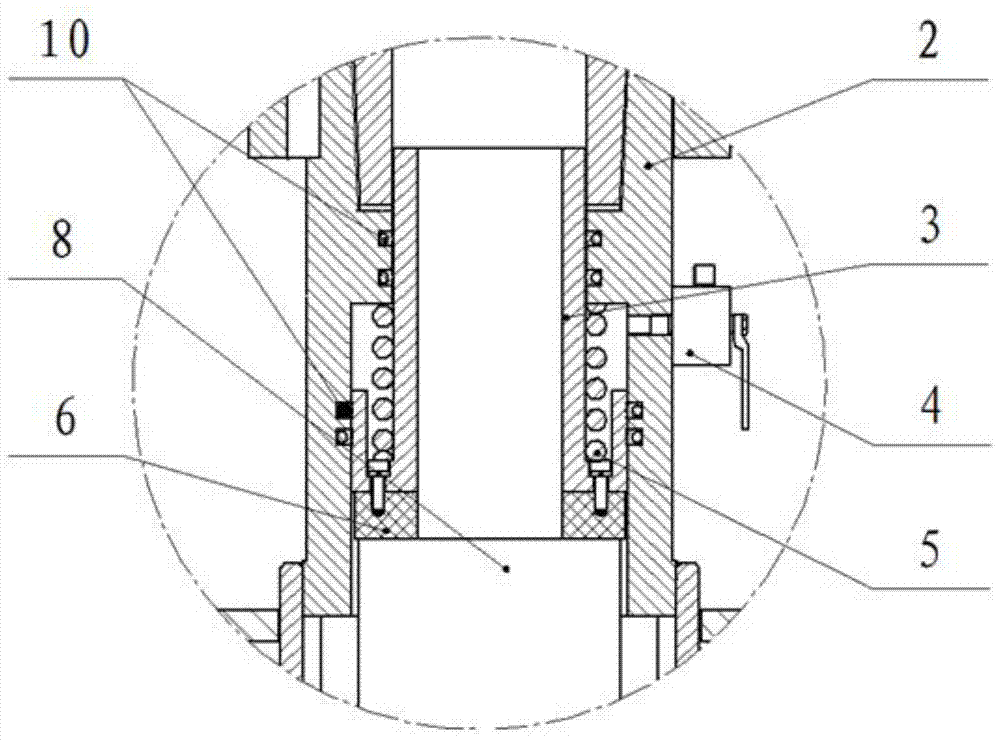

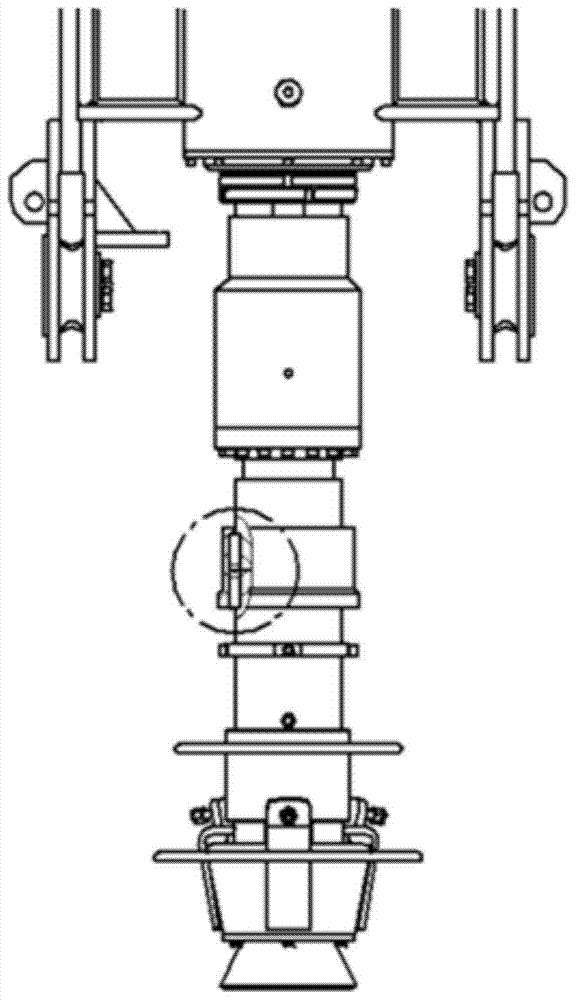

[0027] see figure 1 with 2 , shows the twist-transferable self-sealing drilling tool lifting device of the present invention.

[0028] The torsion-transferable self-sealing drilling tool lifting device includes a joint body 2, a floating core pipe 3, a torsion-transmission slip 7 and a basket 9, wherein the joint body 2 can be connected to the drive shaft of the rotator of the drilling rig, In order to obtain rotational power from the drill gyrator, the joint body 2 contains a floating core tube 3 that can float up and down. The lower end of the joint body 2 is connected with a detachable basket 9, the upper part of the joint body 2 is a straight cylinder, the lower part is a tapered cylinder, and the twist transmission slips 7 are multiple A drill tool 8 is placed in the conical cylinder at intervals, and a drilling tool 8 is passed through a plurality of torque transmission slips 7 in the joint body 2, and the top end can abut against the lower end of the floating core pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com