Swing type porous barrier energy absorption and vibration reduction water tank structure applied to nuclear power plant shield building

A technology for shielding workshops and porous baffles, which is applied to building components, building structures, and shock-proofing, can solve the problems of complex design of frequency-modulated liquid dampers, and achieve the effects of simple structure, low cost, and stable vibration damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

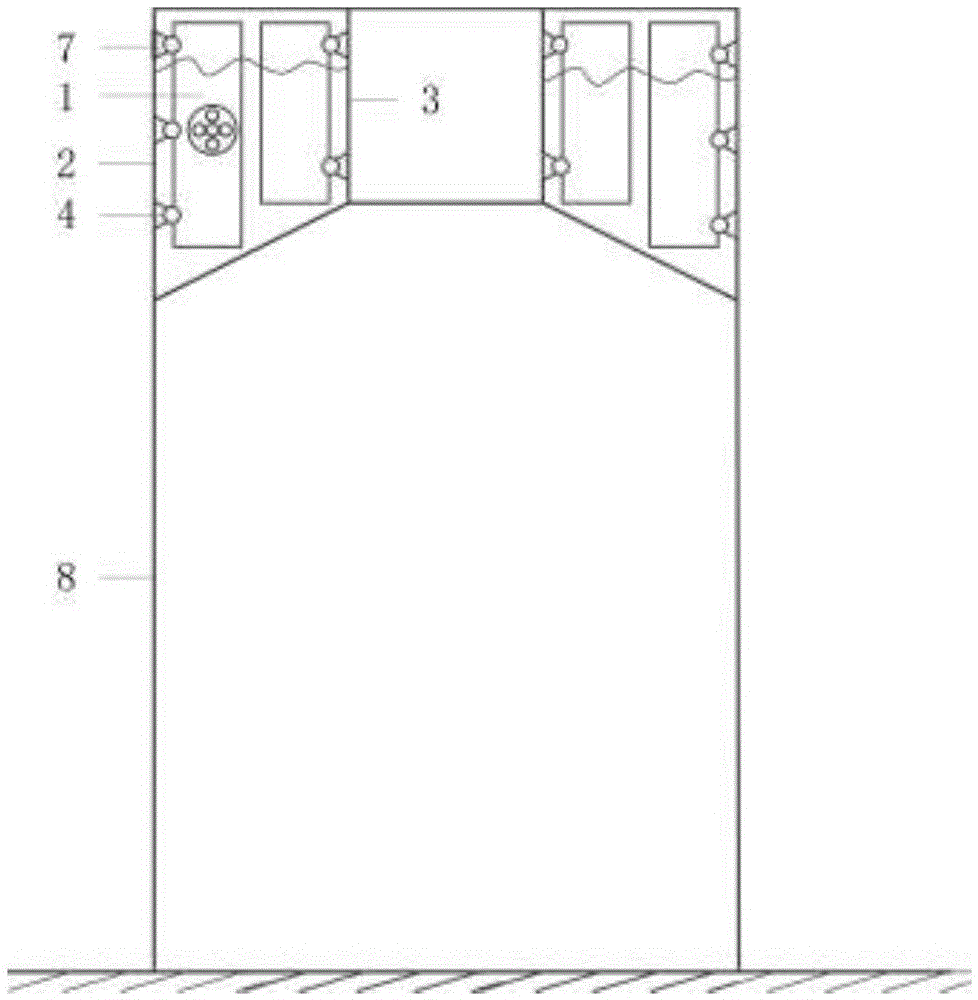

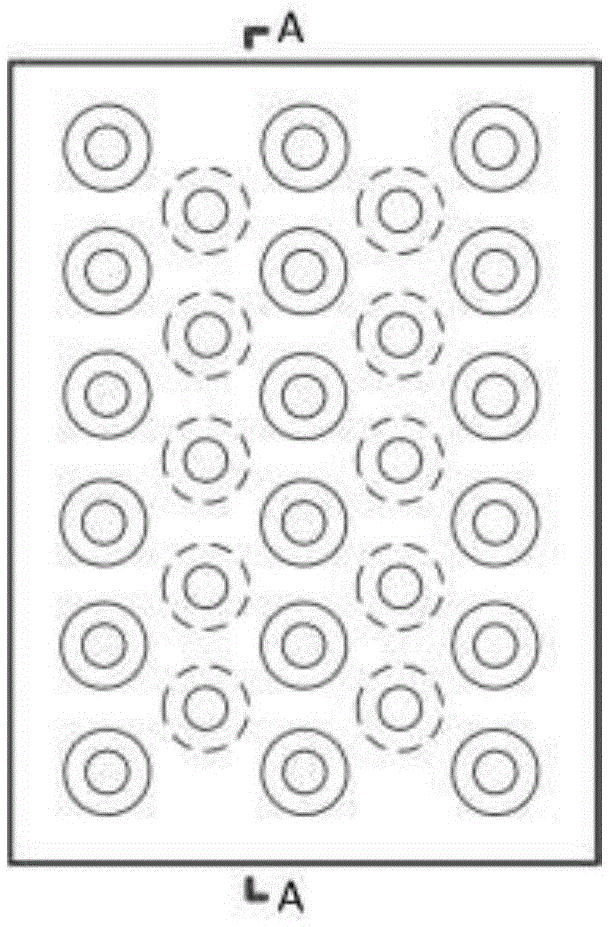

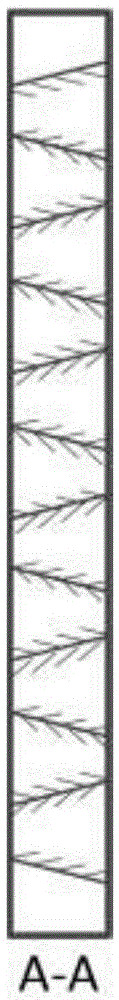

[0024] Embodiment 1: The embedded part provided on the water tank wall refers to the embedded part provided on the inner wall of the water tank or the embedded part provided on the water tank wall refers to the embedded part provided on the outer wall of the water tank. The implementation here is to reserve a certain number of embedded parts 7 on the outer wall 2 or inner wall 3 of the water tank, then weld and install the hinged seat 4, and install the perforated plate 1 on it, and finally install the spring element 5 and the damping element 6 according to the requirements. Install in place.

Embodiment approach 2

[0025] Embodiment 2: When both the inner wall of the water tank and the outer wall of the water tank are provided with embedded parts, the embedded parts on the inner wall of the water tank and the embedded parts on the underwater outer wall are arranged facing each other. This embodiment is to reserve a certain number of embedded parts 7 at the corresponding positions of the outer wall 2 and the inner wall 3 of the water tank, then weld and install the hinged seat 4, and install the perforated plate 1 on it, and finally install the spring element 5 and the damping element 6 according to the requirements in place.

Embodiment approach 3

[0026] Embodiment 3: When both the inner wall of the water tank and the outer wall of the water tank are provided with embedded parts, the embedded parts on the inner wall of the water tank and the embedded parts on the underwater outer wall are arranged alternately. This kind of implementation is to reserve a certain number of embedded parts 7 on the outer wall 2 and the inner wall 3 of the water tank, then weld and install the hinge seat 4, and install the perforated plate 1 on it, and finally install the spring element 5 and the damping element 6 according to the requirements. in place.

[0027] Option 1 is more economical than Option 2 and Option 3, and the installation is more convenient. It has less impact on the volume of the water tank, but the vibration reduction effect is relatively poor. Compared with Scheme 1 and Scheme 3, Scheme 2 has a more stable and excellent vibration reduction effect of the symmetrical installation structure, which has a certain impact on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com