Rotary hoisting equipment for stiffening beam of suspension bridge and erecting method of stiffening beam

A technology for hoisting equipment and stiffening beams, which is applied in the field of rotating hoisting equipment for stiffening beams of suspension bridges and the erection of stiffening beams, and can solve problems such as uneconomical, difficult construction of cable crane frames, poor safety and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

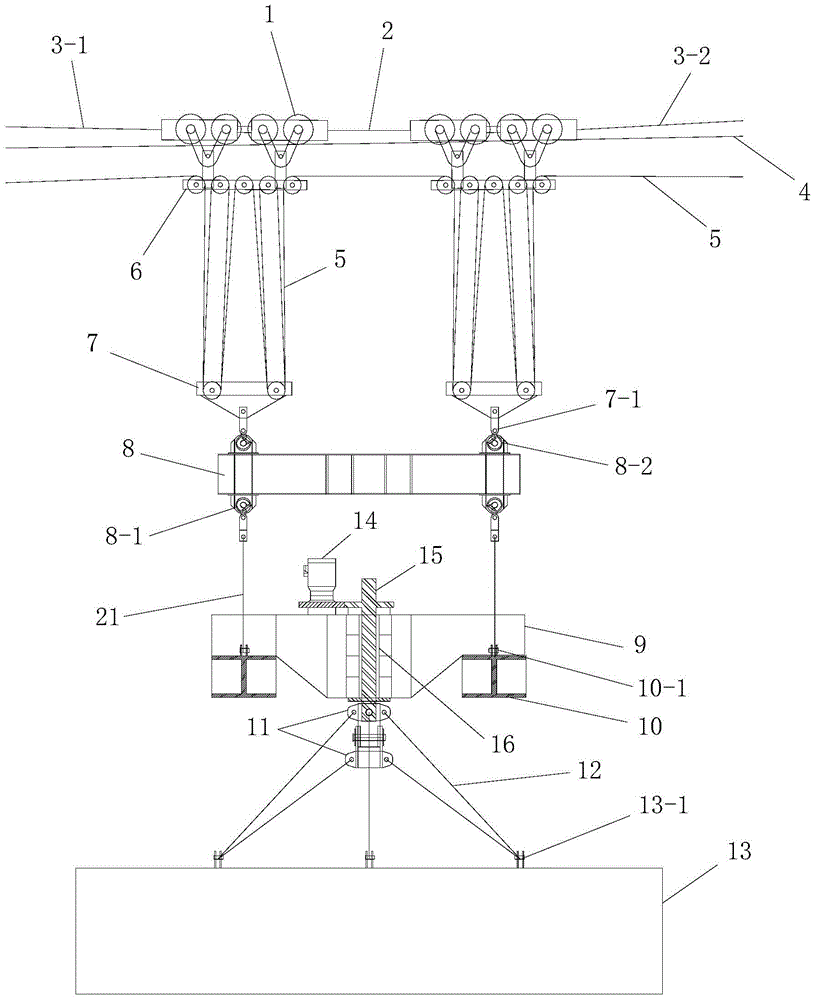

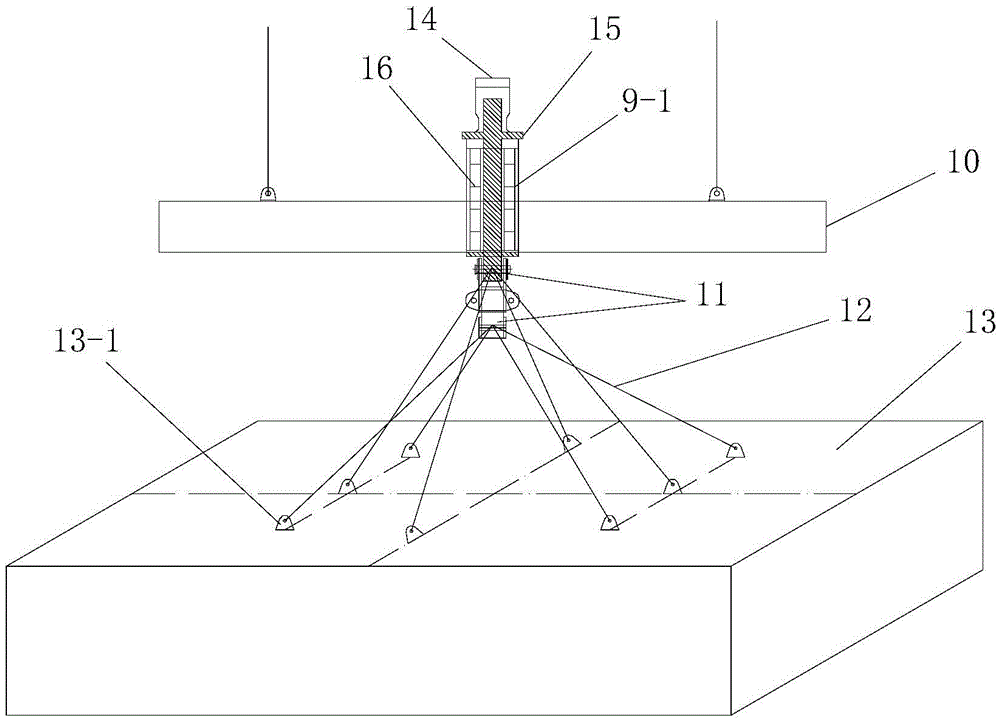

[0065] Such as figure 1A suspension bridge stiffening beam rotating hoisting equipment shown, including hoisting the stiffening beam section 13 and rotating the hoisting stiffening beam section 13 horizontally rotating sling 9, and a pole beam 8 located directly above the slinging sling 9 And the hoisting mechanism that hoists the rotating hoist 9 through the shoulder pole beam 8 and can move forward and backward along the longitudinal bridge direction. The hanger 9 is hoisted on the shoulder pole beam 8 and it is located directly below the shoulder pole beam 8, and the shoulder pole beam 8 is hoisted on the lifting mechanism and it is located below the lifting mechanism. The hoisting mechanism is installed on the cable tower 20 of the suspension bridge under construction; the rotating sling 9 includes a hoisting frame, a vertical shaft installed on the hoisting frame, and a rotary drive mechanism that drives the vertical shaft to rotate horizontally , the stiffening beam sec...

Embodiment 2

[0127] In this embodiment, the structure and connection relationship of the suspension bridge stiffening beam rotary hoisting equipment used are the same as those in Embodiment 1.

[0128] In this embodiment, the suspension bridge stiffening beam erection method adopted is different from Embodiment 1 in that: in step one, the front side beam body is erected, and in step four, the rear side beam body 24 is erected; When installing the hoisting balance mechanism in step 2, a balance cable hoist 18 is installed at the front end of the front side beam body; when erecting the middle beam body in step 3, multiple stiffening beam sections 13 Carry out erection respectively, the erection method of a plurality of described stiffening beam sections 13 is all the same; When any one described stiffening beam section 13 is erected, the process is as follows:

[0129] Step 301, longitudinal translation of the beam section: use the beam transport trolley 19 to translate the currently erected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com