Polyurethane dry process middle layer, polyurethane synthetic leather and preparation method thereof

A polyurethane and synthetic leather technology, applied in the field of synthetic leather, can solve the problems of poor wear resistance and scratch resistance, and achieve the effect of strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

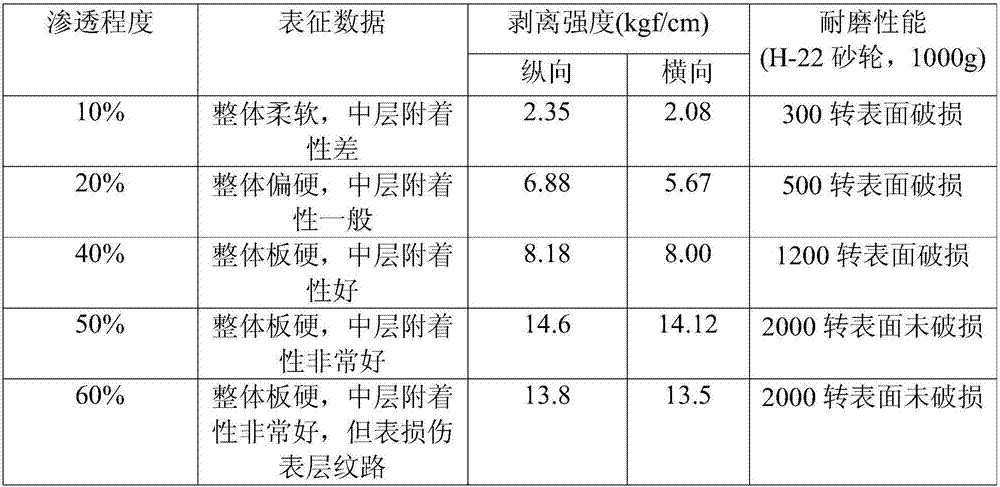

Examples

Embodiment 1

[0025] A polyurethane dry-process middle layer, calculated according to parts by weight, its formula is:

[0026] The hydrolysis-resistant polyurethane is 80 parts of Asahikawa Chemical (XCS-3082S), 30 parts of calcium carbonate, and the polyurethane curing agent is Asahikawa (XAC-77)-curing agent (the content of isocyanate is 13-14%) 5 parts , 15 parts each of ethyl acetate and dimethylformamide.

[0027] The preparation method is as follows: dissolve Asahikawa Chemical (XCS-3082S) in ethyl acetate and dimethylformamide, and stir evenly, then slowly add calcium carbonate and store the stirred material for production, and quickly add Asahikawa (XCS-3082S) before production XAC-77)-The curing agent should be stirred quickly, and it should be used as soon as possible after stirring evenly (this step avoids the failure of the NCO active group of the curing agent).

[0028] A polyurethane synthetic leather, comprising a polyurethane dry-process surface layer, a polyurethane dry-p...

Embodiment 2

[0030] A polyurethane dry-process middle layer, calculated in parts by weight, comprises the following components:

[0031] 70 parts of hydrolysis-resistant polyurethane with a molecular weight of 350,000-400,000, 20 parts of lignocellulose and diatomaceous earth, 2 parts of polyurethane curing agent (the content of isocyanate is 10%) and 40 parts of dimethylformamide.

[0032] The preparation method is as follows: dissolve the hydrolysis-resistant polyurethane in dimethylformamide, and stir evenly, then slowly add lignocellulose and diatomaceous earth to store the stirred material for production, and quickly add polyurethane curing agent before production. Stir quickly, and use it as soon as possible after stirring evenly (this step prevents the NCO active group of the curing agent from becoming invalid).

[0033] A polyurethane synthetic leather, comprising a polyurethane dry-process surface layer, a polyurethane dry-process middle layer and a substrate layer, the polyuretha...

Embodiment 3

[0035] A polyurethane dry-process middle layer, calculated in parts by weight, comprises the following components:

[0036] 100 parts of hydrolysis-resistant polyurethane with a molecular weight of 100,000-150,000, 30 parts of lignocellulose and diatomaceous earth, 8 parts of polyurethane curing agent (with an isocyanate content of 15%) and 60 parts of butyl acetate.

[0037] The preparation method is as follows: dissolve the hydrolysis-resistant polyurethane in butyl acetate, and stir evenly, then slowly add lignocellulose and diatomaceous earth to store the stirred material for production, and quickly add polyurethane curing agent for rapid stirring before production After stirring evenly, use it as soon as possible (this step avoids the NCO active group of the curing agent from being invalidated).

[0038] A polyurethane synthetic leather, comprising a polyurethane dry-process surface layer, a polyurethane dry-process middle layer and a substrate layer, the polyurethane dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com