Laser cladding device for inclined frustum-shaped valve plate sealing faces of large valves

A laser cladding and oblique cone technology, which is applied in the coating process of metal materials, coating and other directions, can solve the problems of powder not accumulating normally, affecting cladding quality, laser beam deviation, etc., and achieves good real-time controllability of power , Optimize the production environment, and achieve uniform cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

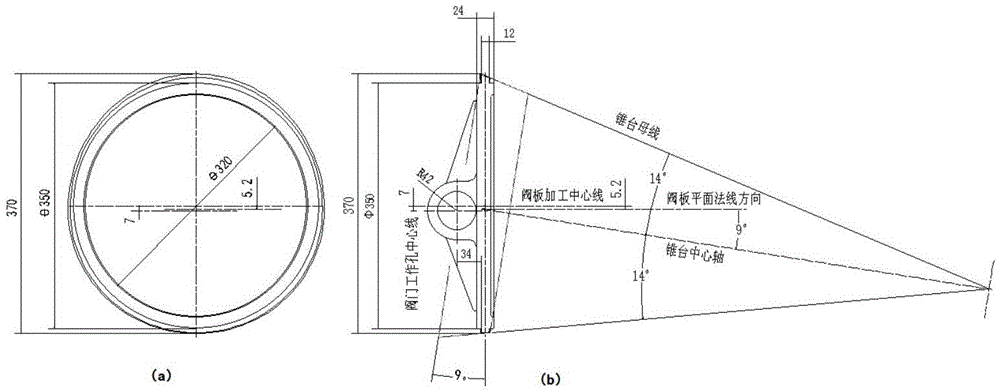

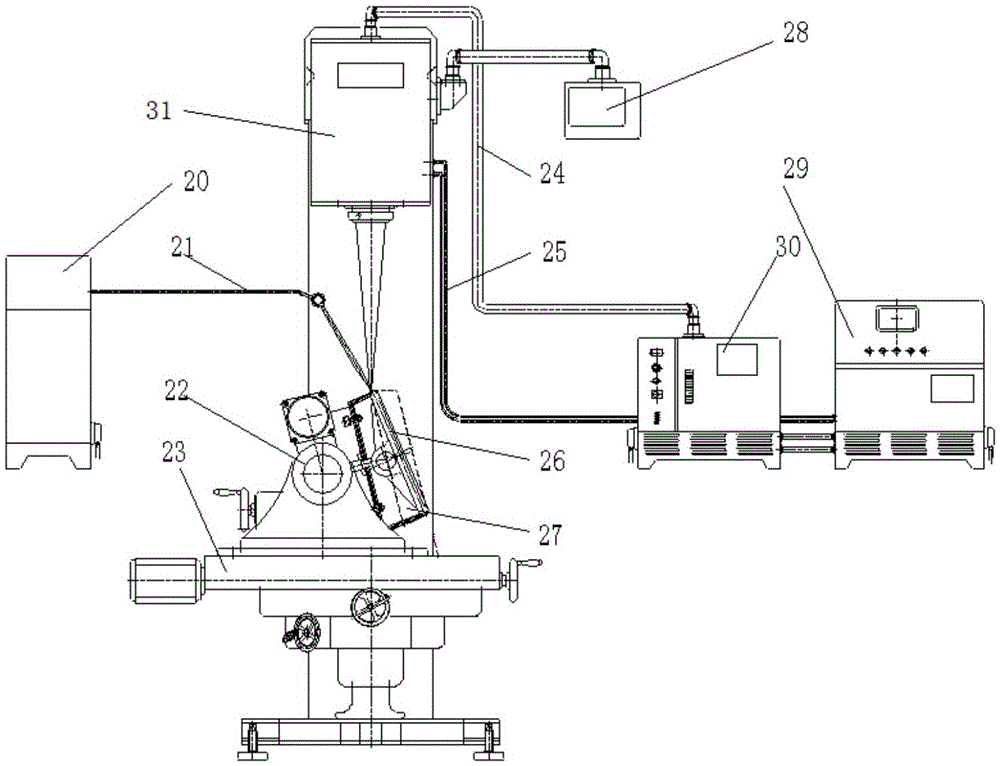

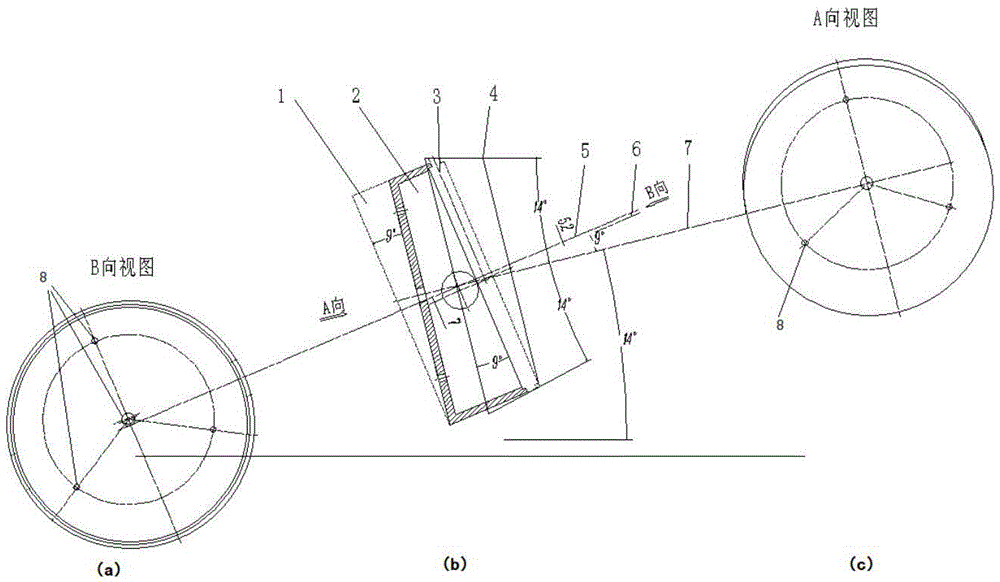

[0051] The specific implementation method is as follows: when the valve plate is placed on the fixture, the center of the valve plate shaft 12 is used as a fixed point to determine the specific positional relationship between the valve plate and the fixture, so that the center axis of the frustum of the valve plate is aligned with the center hole center of the bottom surface of the fixture. lines on the same straight line. The central fixing hole of the fixture is corresponding to the rotary axis of the tiltable rotary table 9, then naturally, the central axis 18 of the cone frustum is on the same straight line as the rotary axis of the turntable.

[0052] When the elevation angle 19 of the rotary table is equal to the included angle between the frustum busbar 13 and the central axis 18 of the frustum, the frustum busbar 13 is horizontal, and when the tiltable rotary table 9 is rotating, the frustum busbar 13 of the special valve plate 15 Always on the same level. This ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com