Adhesive for chemical anchor bolts, and preparation method thereof

A technology of chemical anchor bolts and adhesives, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve problems such as difficult to use in large quantities, decreased strength index, poor weather resistance, etc., to improve the bonding strength , Improve the surface properties, increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

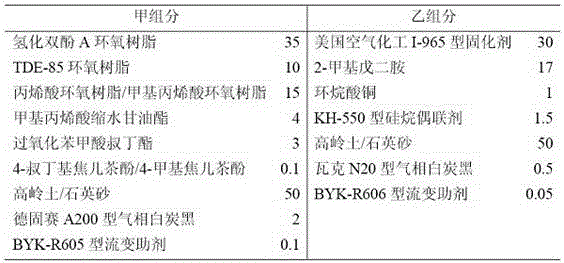

[0064] An adhesive for chemical anchors, which includes component A and component B, and the two components respectively include the following components (in grams):

[0065]

[0066] The preparation method of above-mentioned chemical anchor bolt adhesive is as follows:

[0067] (1) Preparation of component A:

[0068] Weigh the raw materials for component A according to the weight recorded in the above table, first mix 15g of hydrogenated bisphenol A epoxy resin, 30g of TDE-85 epoxy resin, 35g of acrylic epoxy resin, 2g of glycidyl methacrylate, 2g of over Add tert-butyl oxidized benzoate, 0.05g of 4-tert-butylpyrocatechol and 0.05g of BYK-R605 rheological additive into the kneader, stir evenly, then add 30g of cement, stir evenly, and make the system into a paste, Finally, add 0.5g of Degussa A200 type fumed silica in batches, stir for 3-4 hours, discharge, and pack in glass tubes to obtain the finished product of component A;

[0069] (2) Preparation of component B:

...

Embodiment 2

[0075] An adhesive for chemical anchors, which includes component A and component B, and the two components respectively include the following components (in grams):

[0076]

[0077] The preparation method of above-mentioned chemical anchor bolt adhesive is as follows:

[0078] (1) Preparation of component A:

[0079] Weigh the raw materials for component A according to the weight recorded in the above table, first mix 25g of hydrogenated bisphenol A epoxy resin, 25g of TDE-85 epoxy resin, 20g of methacrylic acid epoxy resin, 3g of glycidyl methacrylate , 2.5g of tert-butyl peroxybenzoate, 0.06g of 4-methylpyrocatechol and 0.07g of BYK-R606 rheological additives were added to the kneader, stirred evenly, and then 40g of talcum powder was added, stirred evenly, and the system into a paste, and finally add 0.6g WACKER N20 type fumed silica in batches, stir for 3~4 hours, discharge, and plastic flexible packaging to obtain the finished product of component A;

[0080] (2) P...

Embodiment 3

[0086] An adhesive for chemical anchors, which includes component A and component B, and the two components respectively include the following components (in grams):

[0087]

[0088] The preparation method of above-mentioned chemical anchor bolt adhesive is as follows:

[0089] (1) Preparation of component A:

[0090] According to the weight recorded in the above table, take the raw materials that make up component A, first mix 35g hydrogenated bisphenol A epoxy resin, 10g TDE-85 epoxy resin, 15g acrylic epoxy resin / methacrylic epoxy resin mixture, 4g formazan Glycidyl acrylate, 3g tert-butyl peroxybenzoate, 0.1g 4-tert-butylpyrocatechol / 4-methylpyrocatechol mixture and 0.1g BYK-R605 rheology additive were added to the kneader , stir evenly, then add 50g of kaolin / quartz sand mixture and stir evenly to make the system into a paste, and finally add 2g of Degussa A200 type fumed silica in batches, stir for 3~4h, discharge, and pack in glass tubes to obtain Component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com