Sound absorption and insulation sheet material and preparation method thereof

A board and sound absorption technology, applied in the field of sound absorption and sound insulation board and its preparation, can solve the problems of complex production process, slow project progress, low flexural strength, etc., and achieve the effects of excellent sound absorption performance, reduced bulk density and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

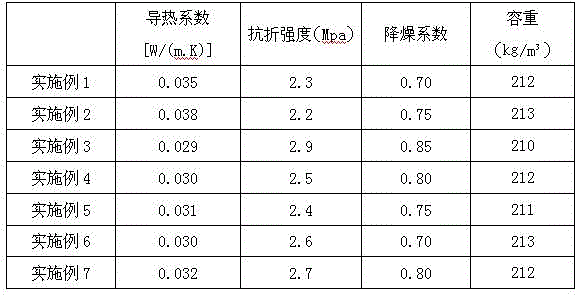

Examples

Embodiment 1

[0018] A sound-absorbing and sound-insulating board, consisting of the following components by weight: 50 parts of cement, 20 parts of ceramsite, 30 parts of garbage ceramsite, 6 parts of silica sol, 5 parts of starch, 3 parts of water-repellent agent, and 1 part of carbon fiber 1 part, foaming agent 1 part, water 7 parts.

Embodiment 2

[0020] A sound-absorbing and sound-insulating board, which is composed of the following components in parts by weight: 80 parts of cement, 30 parts of ceramsite, 40 parts of garbage ceramsite, 10 parts of silica sol, 8 parts of starch, 5 parts of water repellent, and 8 parts of carbon fiber parts, foaming agent 3 parts, water 15 parts.

Embodiment 3

[0022] A sound-absorbing and sound-insulating board is composed of the following components by weight: 65 parts of cement, 25 parts of ceramsite, 35 parts of garbage ceramsite, 8 parts of silica sol, 7 parts of starch, 4 parts of water repellent, and 5 parts of carbon fiber , 2 parts of foaming agent, 10 parts of water. Wherein, the weight ratio of the garbage ceramsite with two particle diameters is 1:1, the water-repellent agent is calcium stearate, and the foaming agent is hydrogen peroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com