A Seam Tracking Sensor Structure

A sensor and welding torch technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low convenience and reliability, and achieve good self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a detailed description of the embodiments of the present invention. This embodiment takes the present invention as a technical solution for implementation, and has detailed implementation methods and specific operation processes. The protection scope of the present invention is not limited to the following examples.

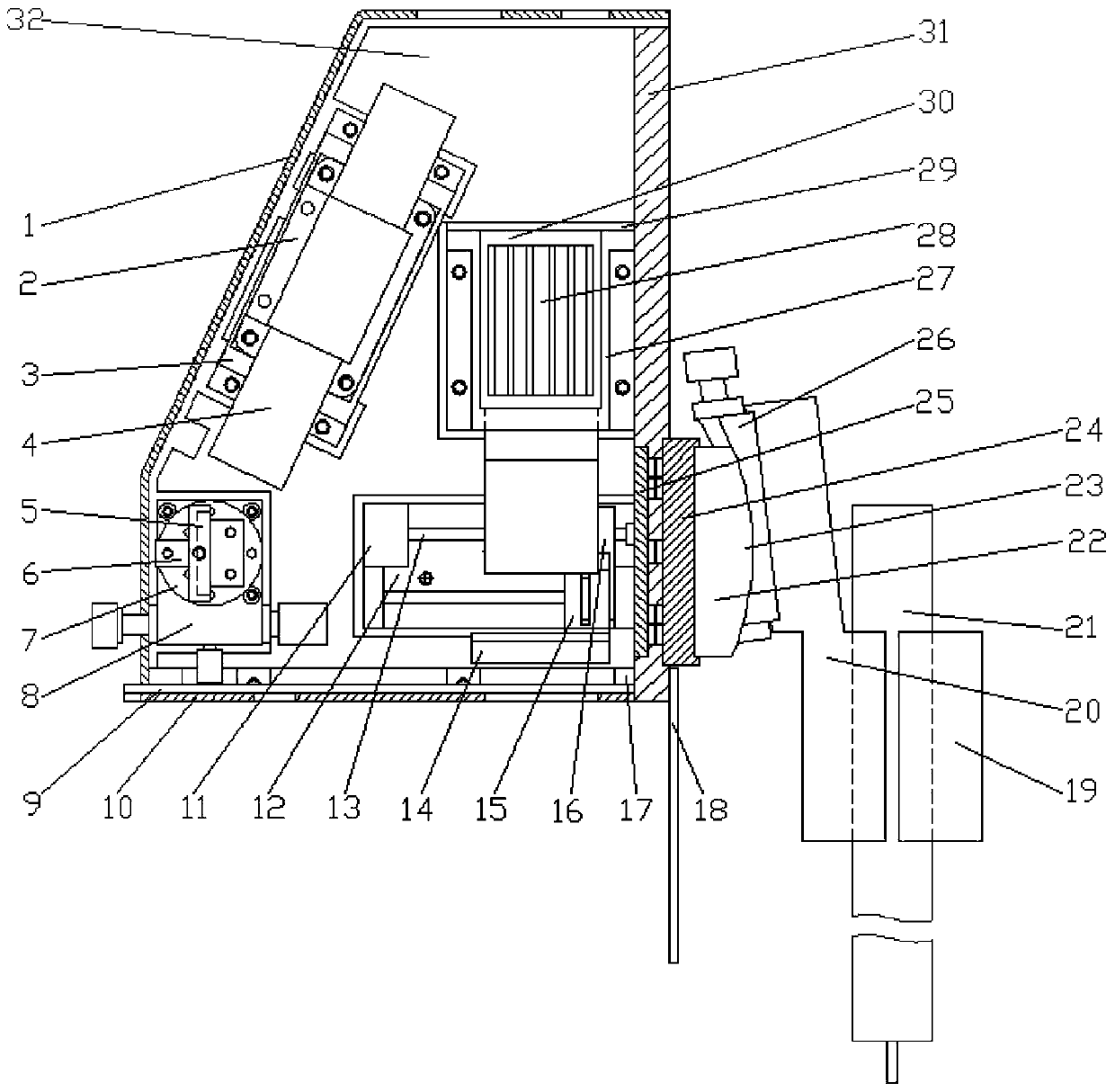

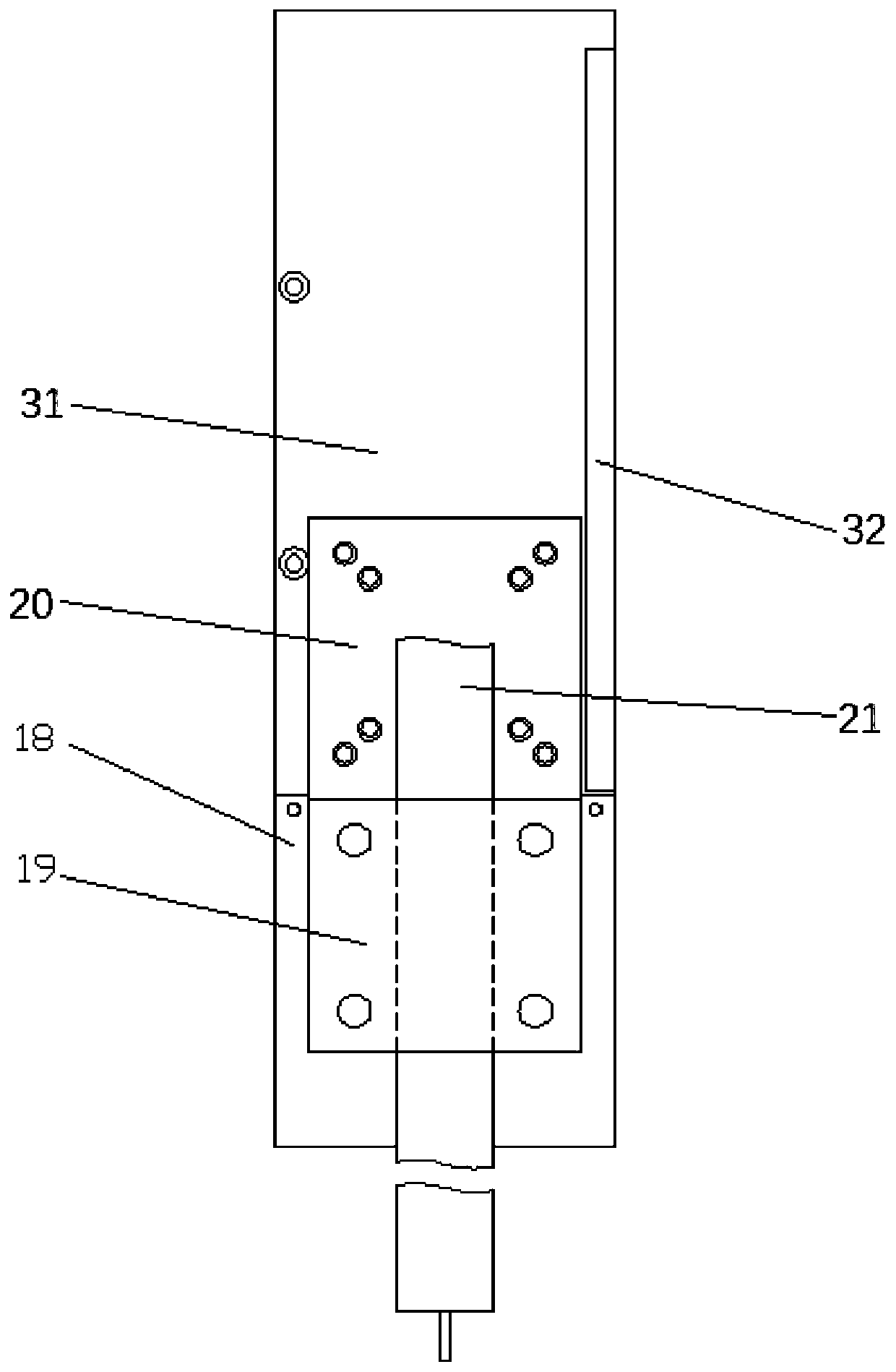

[0025] Such as figure 1 and figure 2 As shown, a seam tracking sensor structure, including: support and fixed inner

[0026] The bottom plate 32 of each component of the department; the right side plate 31 connecting the bottom plate 32 and the corner platform 23; the side bending plate 1 that protects the internal components; the laser bracket 3 used to support the laser sleeve 2 and position it. There is a rectangular groove on the top to install the laser sleeve 2, and the bottom is installed in the two rectangular grooves on the bottom plate 32; In the groove; the reflector bracket 6 is fixed on the turntable table 7 of the manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com