Method and system for detecting and classifying defective products

A classification method and bad technology, applied in sorting and other directions, can solve problems such as high labor intensity, increased equipment cost, and reduced effectiveness, and achieve the effects of increasing the scope of application, reducing labor costs, and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

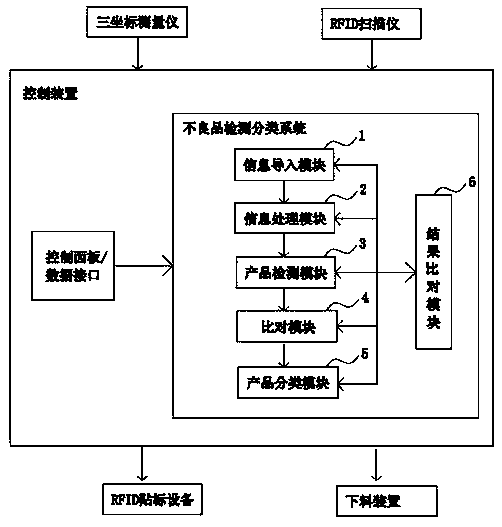

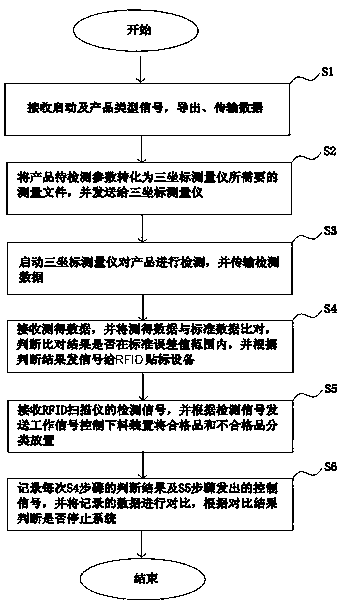

[0036] The invention discloses a defective product detection and classification device, as attached figure 1 As shown, a control device is included, the control device includes a control panel and a data serial port, various parameters can be input through the control panel, and the control device is respectively connected to a coordinate measuring instrument, RFID labeling equipment, RFID scanner And the blanking device, the control device controls the detection process of the three-coordinate measuring instrument and controls the work of the RFID l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com