Automatic wire-stripping machine for flexible flat cables

A wire stripping machine and automatic technology, which is applied in the direction of cable installation devices, electrical components, equipment for dismantling/armored cables, etc., can solve the problems of unfavorable enterprise development needs, excessive stripping force, and inability to peel them off, etc. , to achieve the effects of not easy to shift, low production cost, and fixed wire position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

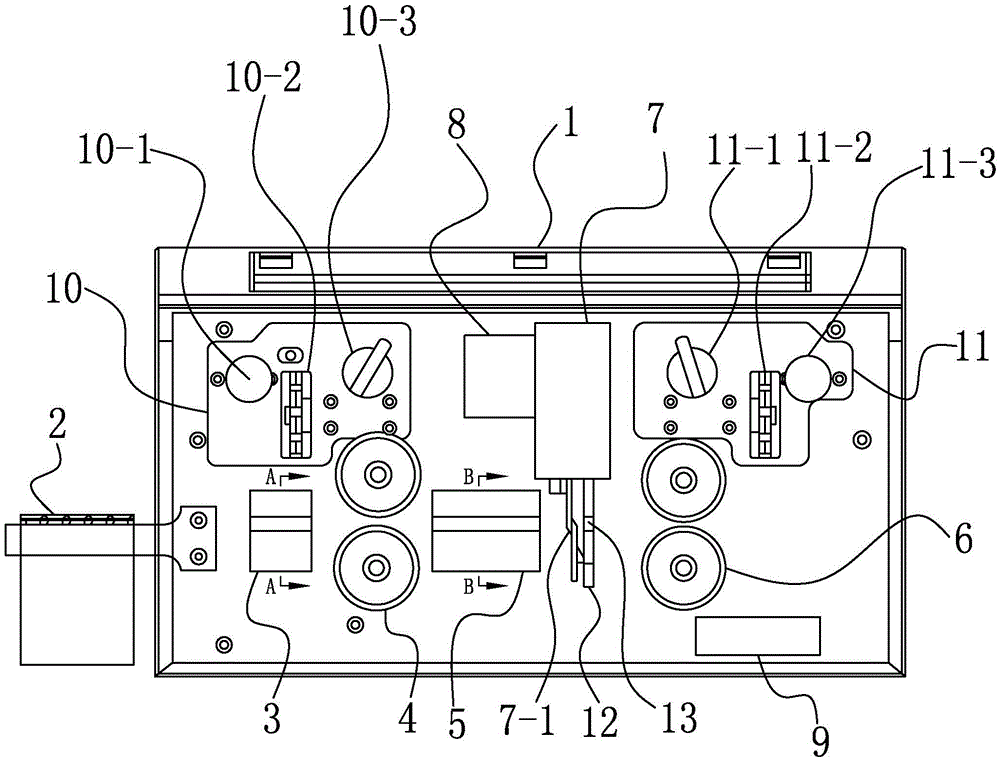

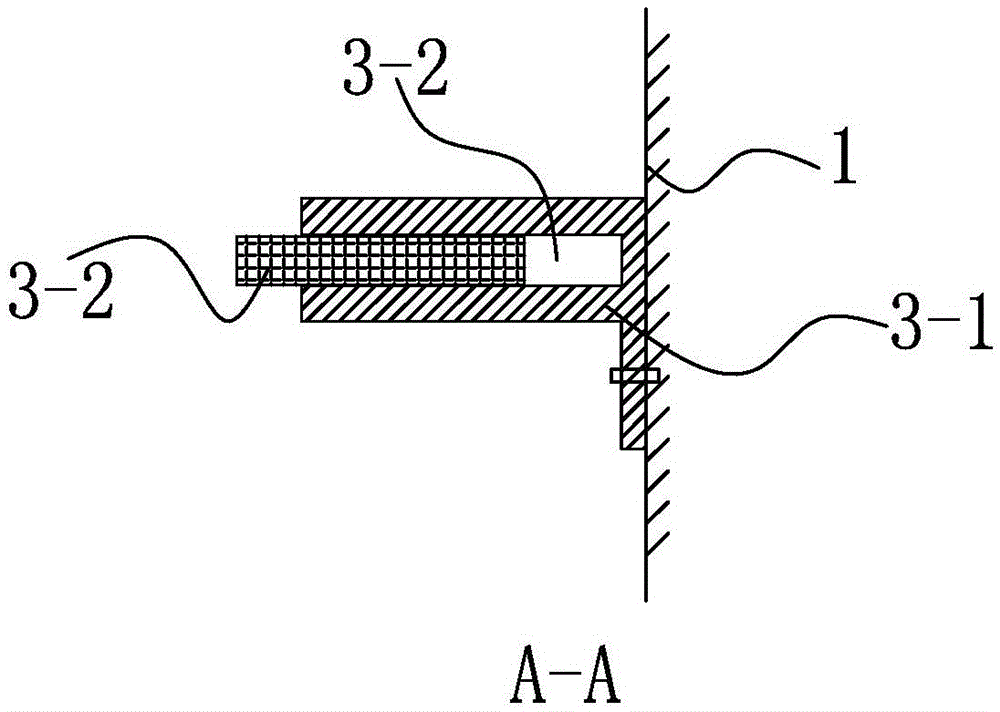

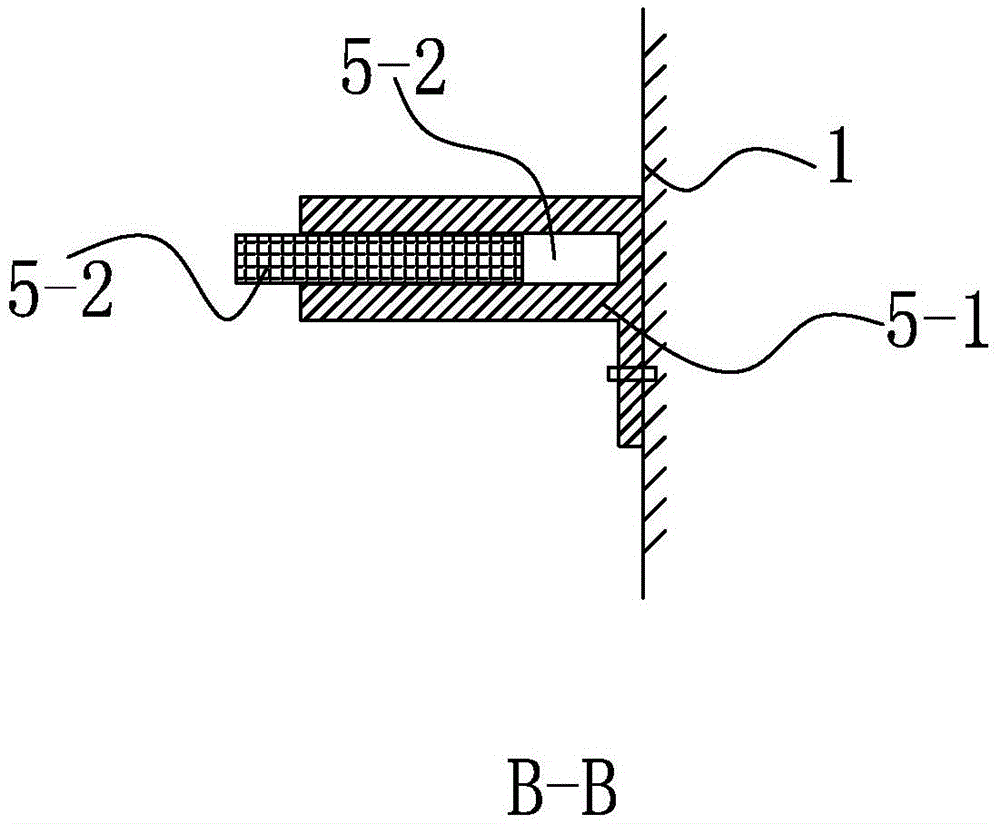

[0021] Embodiment: an automatic cable arrangement and stripping machine, including a chassis 1; the outer wall of the chassis 1 is provided with a feeding device 2, a positioning device 3, a front roller group 4, an adjustment device 5 and a rear roller group 6 in sequence from right to left; Between the adjustment device 5 and the rear roller group 6, a wire cutting and stripping device 7 for wire arranging and stripping is provided; the feeding device 2 feeds the arranging wire, and is positioned by the operation of the positioning device 3; the upper end of the wire cutting and stripping device 7 A motor 8 is provided on the side wall, and the motor 8 drives the wire cutting and stripping device 7 to carry out the wire stripping process. The front roller group 4 includes two rollers arranged vertically. Correspondingly, the rear roller group 6 also includes two rollers arranged longitudinally. Two rollers, the front roller group 4 and the rear roller group 6 clamp the cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com