Fixing structure and fixing method for MOS transistor

A technology of MOS tube and fixed structure, applied in the field of MOS tube fixed structure and fixing, can solve the problems of breakdown and low assembly efficiency, and achieve the effects of flat and close fit, improved work efficiency, and good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

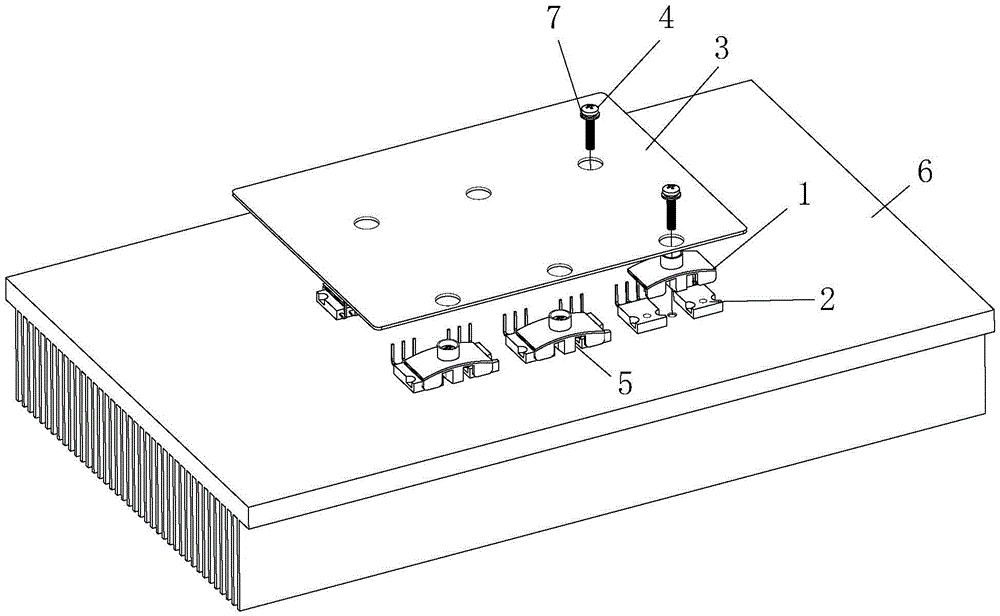

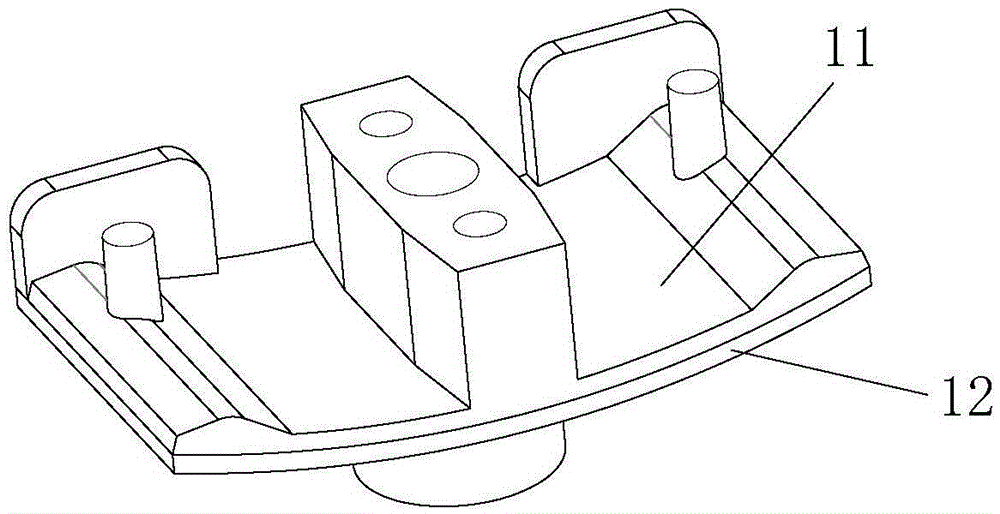

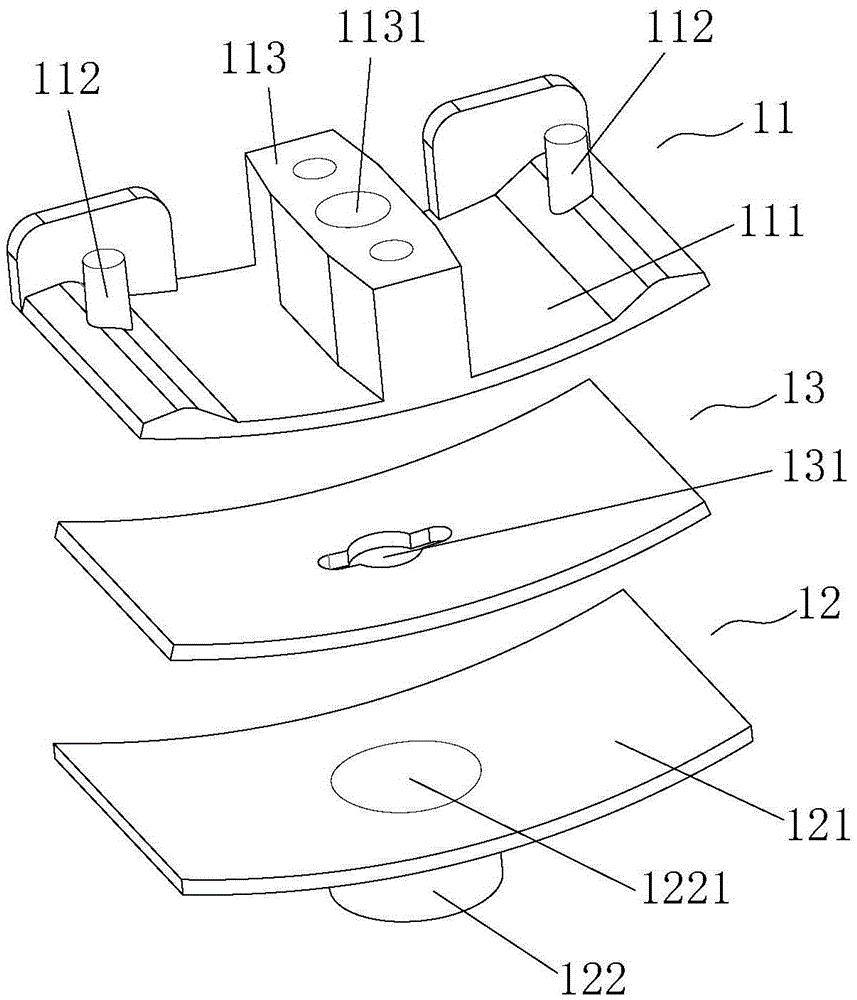

[0029] This embodiment provides a MOS tube fixing structure, so that the MOS tube 2 and the heat sink always have good contact and heat dissipation. In this example, if figure 1 As shown, the pins of the MOS tube 2 are welded on the PCB board 3, and the side of the MOS tube 2 away from the PCB board 3 is provided with a radiator 6; the fixed structure includes an accommodation space formed between the MOS tube 2 and the PCB board 3 5, and one end of it protrudes from the PCB board 3, and the other end is fastened and connected with the MOS tube 2; it also includes a screw 4, the fixing part 1 and the radiator 6 are connected by the screw 4, and the upper end of the screw 4 is clamped on the fixing part 1 protruding from one end of the PCB board 3, and its lower end penetrates from the end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com