Automatic oil immersion method and device for a transformer

A transformer and oil immersion technology is applied in the field of devices using the transformer automatic oil immersion method, which can solve problems such as personal injury and operator injury, and achieve the effect of avoiding participation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

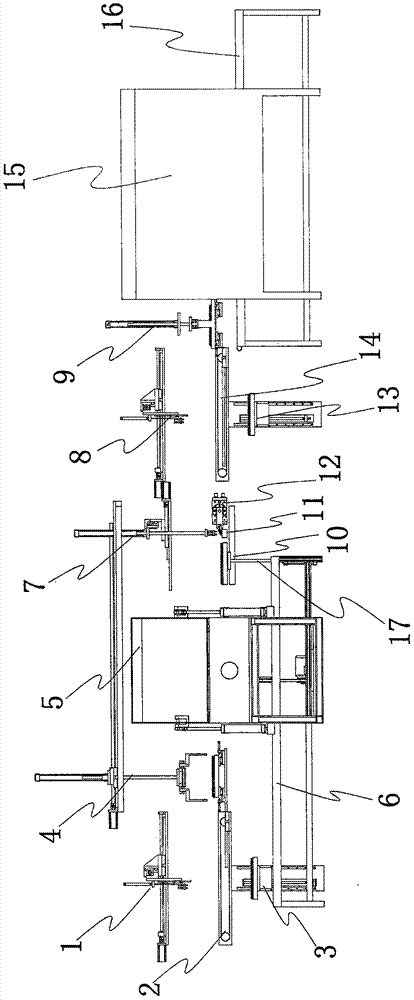

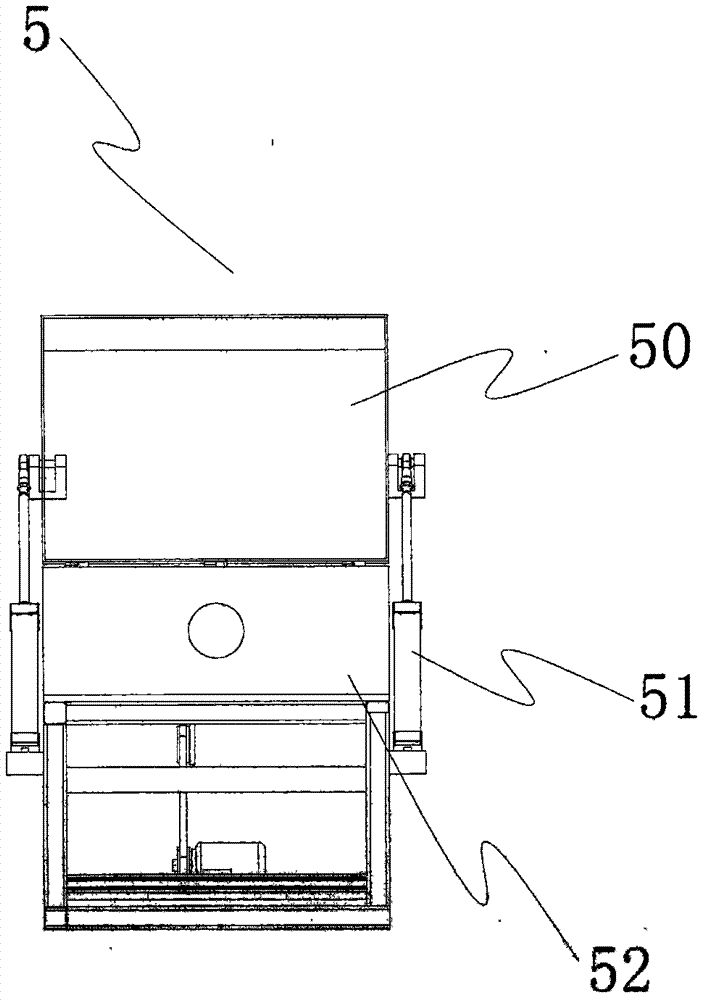

[0040] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

[0041] refer to figure 1 , figure 2 , the present invention provides an automatic oil immersion device for a transformer, including a frame, and also includes a first reclaiming manipulator 1, a second reclaiming manipulator 4, a third reclaiming manipulator 7, a fourth reclaiming manipulator 8, a fifth reclaiming manipulator The reclaiming manipulator 9 , and the first conveying unit 2 , the second conveying unit 14 , and the third conveying unit 16 .

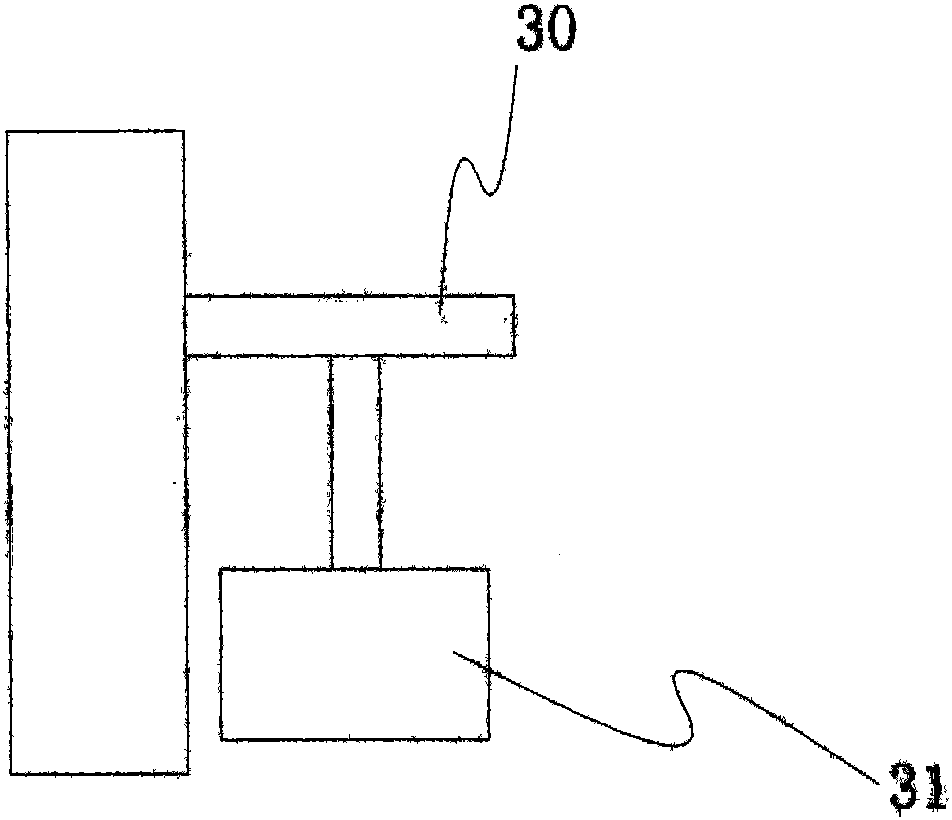

[0042] Among them, the structures of the first reclaiming manipulator 1, the third reclaiming manipulator 7, and the fourth reclaiming manipulator 8 can be exactly the same, and they are all manipulators based on three-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com