Lifting device of a pneumatic truck crane

A lifting device, pneumatic vehicle technology, applied in teaching models, instruments, educational appliances, etc., can solve the problems of hydraulic oil leakage pollution, inconvenient operation, complex system, etc., and achieve the effects of weight reduction, convenient manufacture, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

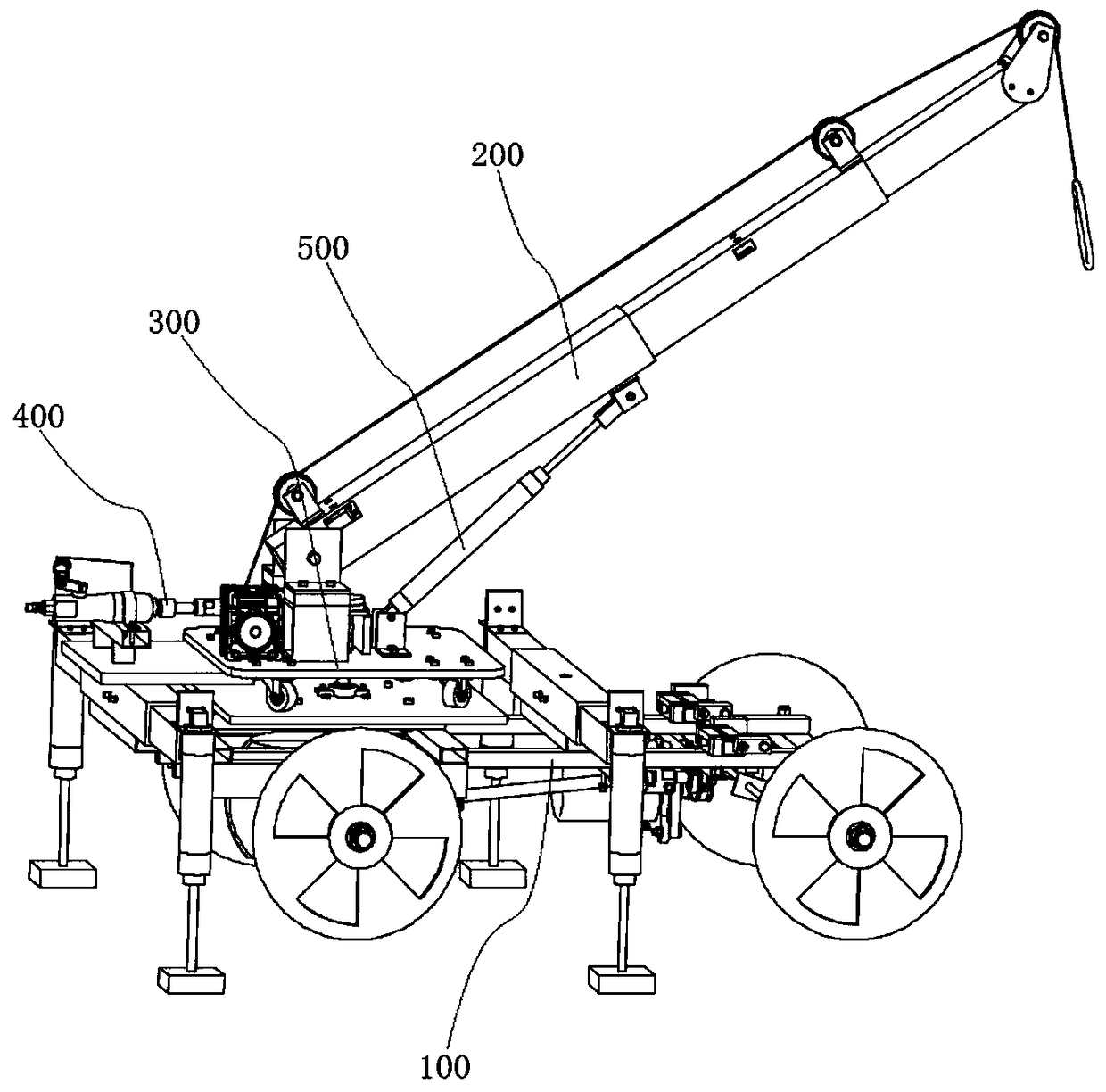

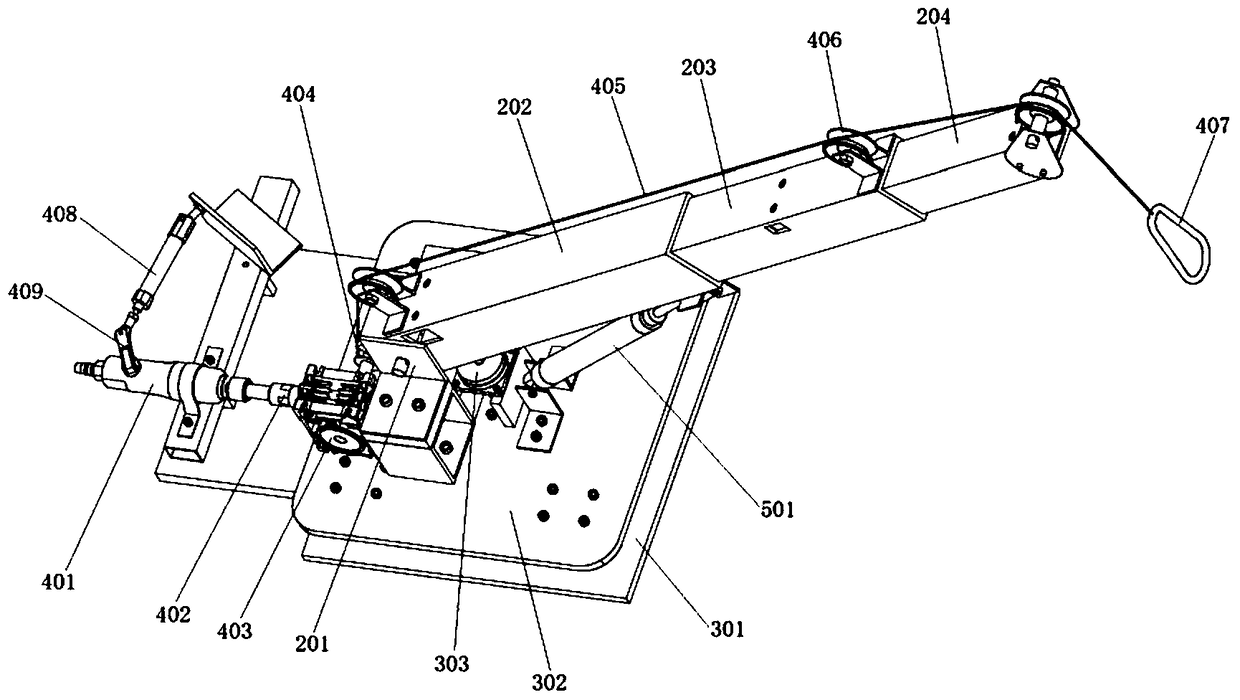

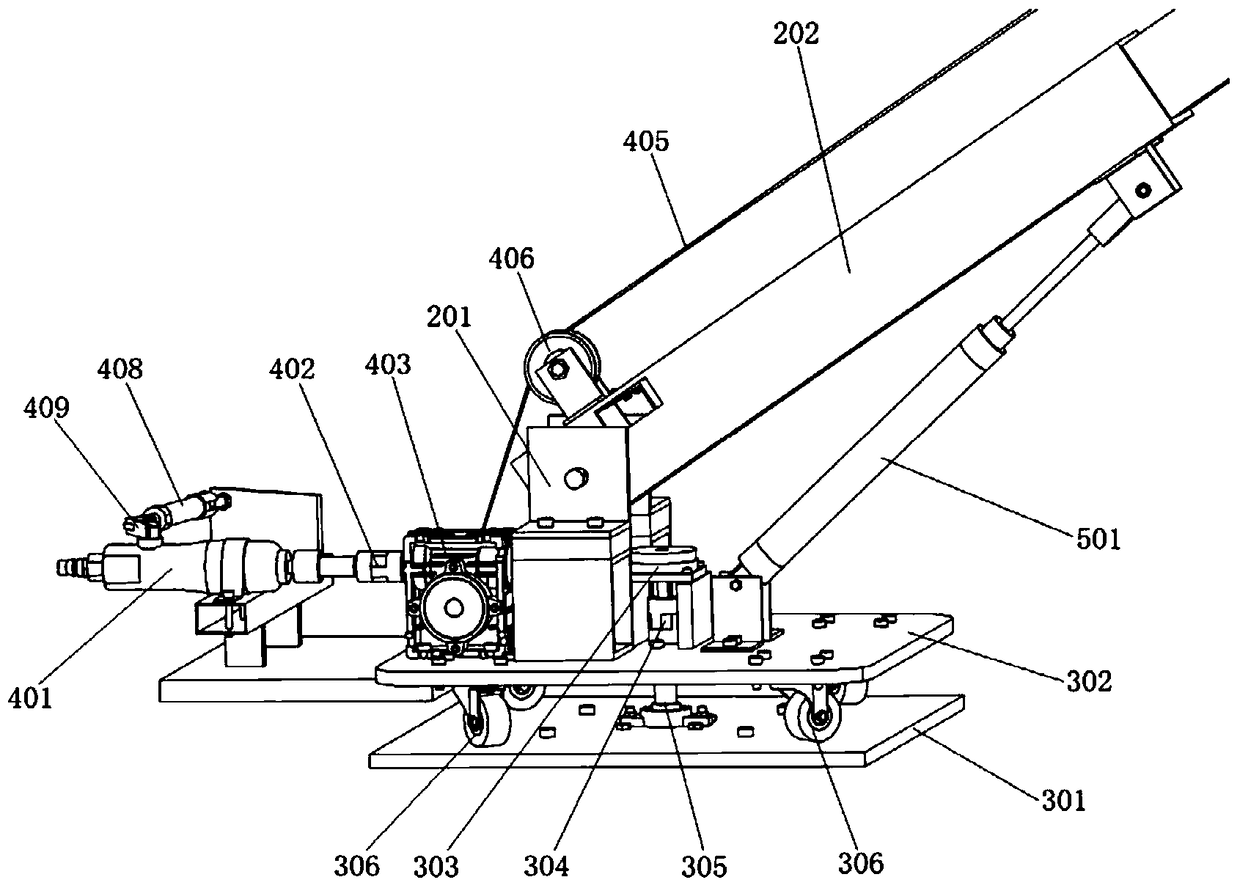

[0034] combine figure 1 , figure 2 and image 3 As shown, the lifting device of a pneumatic truck crane in this embodiment includes a boom 200, a slewing mechanism 300, a hoisting mechanism 400 and a luffing mechanism 500, a boom 200, a slewing mechanism 300, and a hoisting mechanism 400 and the luffing mechanism 500 are all arranged on the automobile chassis 100 of the automobile crane. The automobile chassis 100 is used to support the lifting device and is responsible for the movement of the entire automobile crane; the boom 200 is used to hang and carry the lifted goods. Changing the length and inclination angle to change the lifting height and working radius; the slewing mechanism 300 is used to control the rotation of the boom 200 to carry the goods; the lifting mechanism 400 is used to lift or put down the goods on the hook by retracting and retracting the wire rope; The luffing mechanism 500 is used to control the inclination range of the boom 200 .

[0035] The lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com