An Optimal Method for Adjusting Production Load of Ethylene Cracking Furnace

A technology of an ethylene cracking furnace and an optimization method, which is applied in the optimization field of production load adjustment of an ethylene cracking furnace, and can solve problems such as the decline of ethylene profitability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

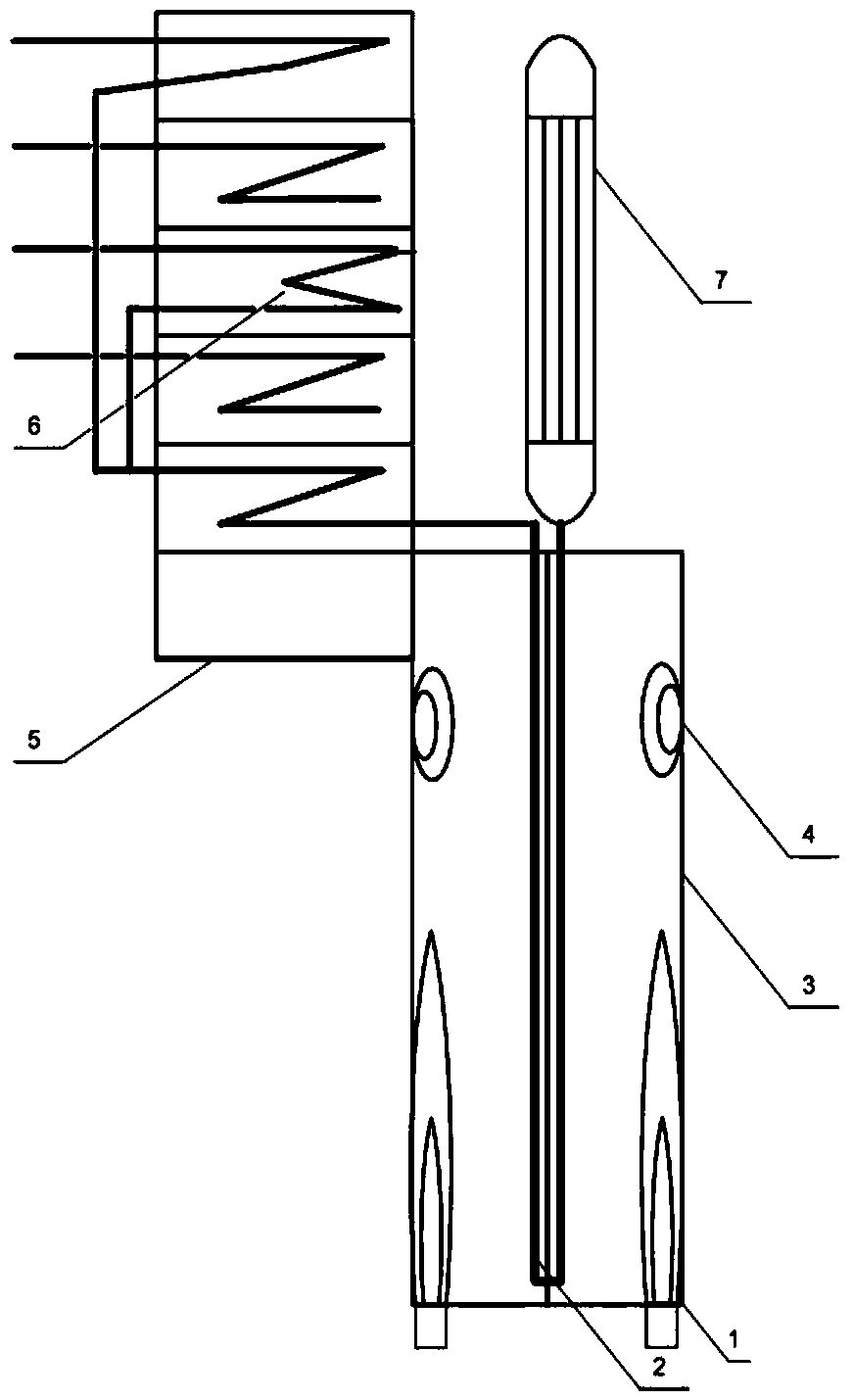

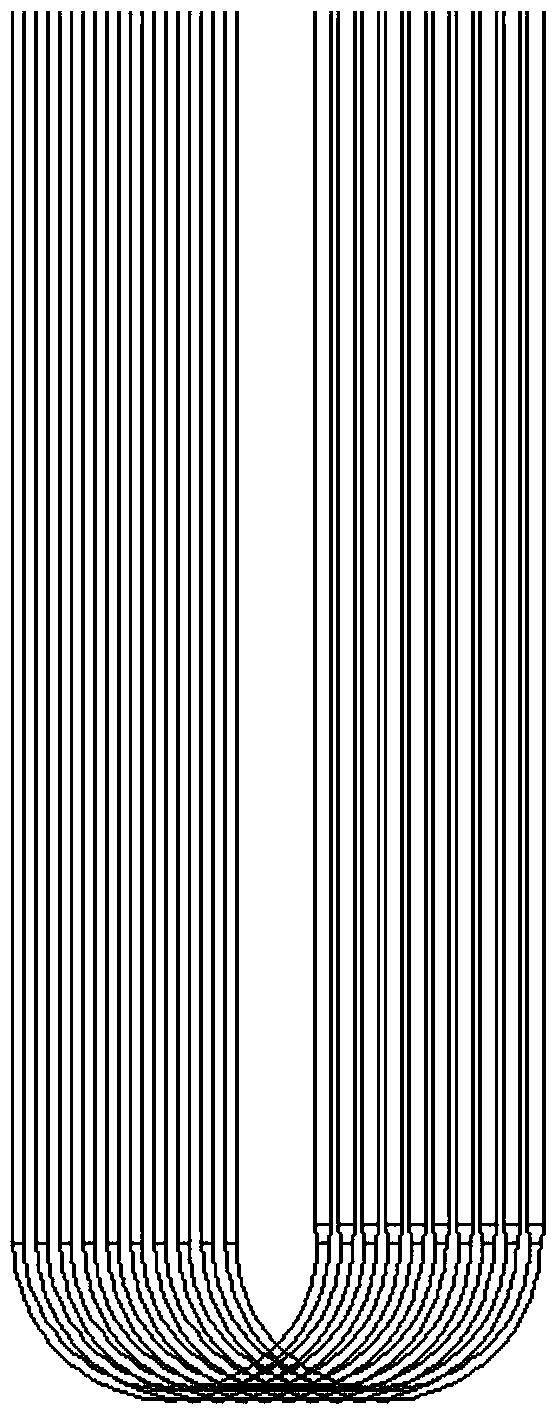

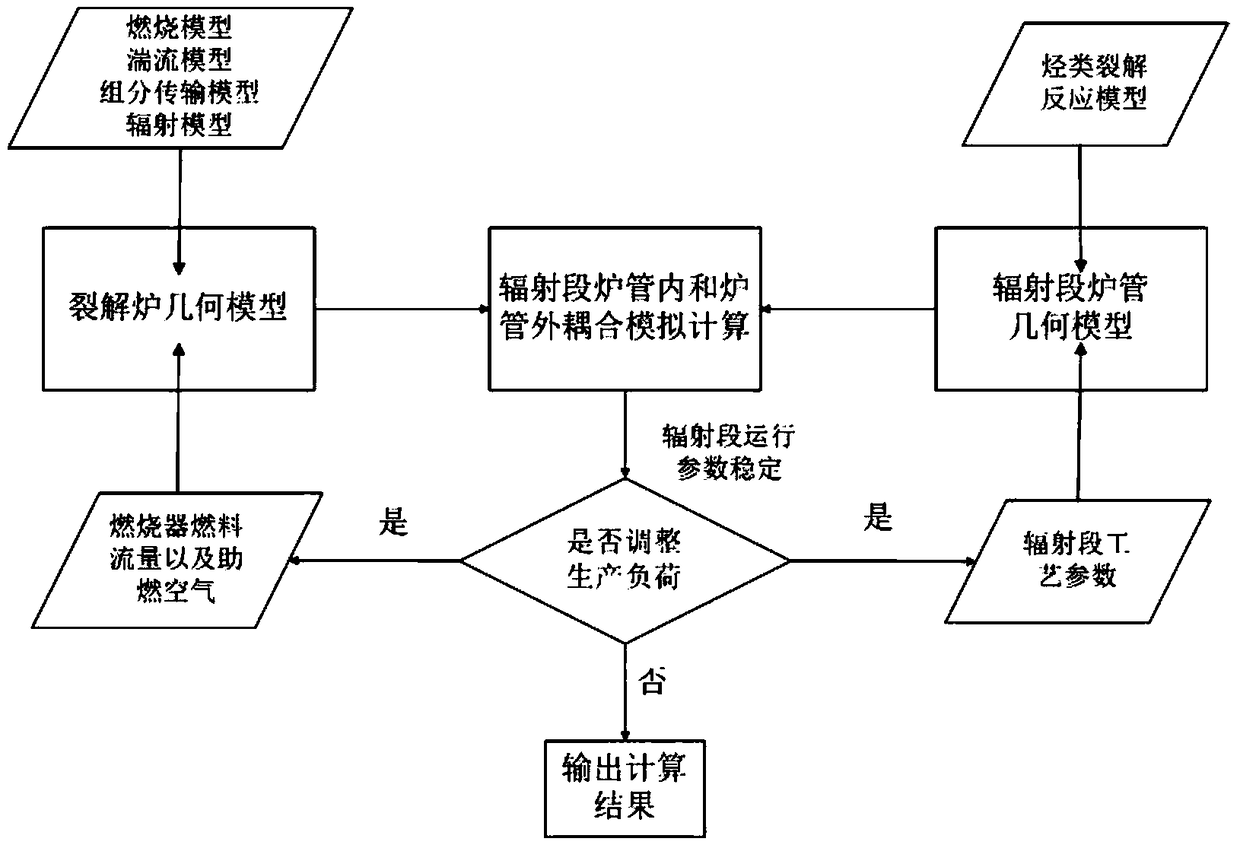

[0049] Such as figure 1 As shown, an ethylene cracking furnace with an annual output of 100,000 tons includes a convection section and a radiation section. The radiation section is composed of 48 groups of 2-1 type furnace tubes, which are divided into 6 groups and arranged in the center of the radiation section. 36 bottom burners are evenly distributed on both sides, and 48 side wall burners are evenly distributed on both sides, arranged in two rows.

[0050] Hydrocarbon feedstocks take a hydrogenation tail oil as an example, the feed rate is 41200kg / h, the weight ratio of dilution steam to hydrocarbon feedstock is 0.75, the inlet and outlet temperatures of the furnace tube in the radiant section are 555°C and 812°C respectively, and the inlet and outlet pressures (gauge pressure ) are 0.19Mpa and 0.11Mpa respectively. When the feed rate is adjusted to 80% load, that is, the feed rate is 32960kg / h, the weight ratio of dilution steam to hydrocarbon feedstock is 0.80, the inle...

Embodiment 2

[0054] Such as figure 1 As shown, an ethylene cracking furnace with an annual output of 100,000 tons includes a convection section and a radiation section. The radiation section is composed of 48 groups of 2-1 type furnace tubes, which are divided into 6 groups and arranged in the center of the radiation section. 36 bottom burners are evenly distributed on both sides, and 48 side wall burners are evenly distributed on both sides, arranged in two rows.

[0055] Hydrocarbon feedstocks take a hydrogenation tail oil as an example, the feed rate is 41200kg / h, the weight ratio of dilution steam to hydrocarbon feedstock is 0.75, the inlet and outlet temperatures of the furnace tube in the radiant section are 555°C and 812°C respectively, and the inlet and outlet pressures (gauge pressure ) are 0.19Mpa and 0.11Mpa respectively. When the feed rate is adjusted to 110% load, that is, the feed rate is 45320 kg / h, the weight ratio of dilution steam to hydrocarbon feedstock, the outlet tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com