Fiber grating intelligent composite material structure based on 3D printing and preparation method thereof

A composite material, 3D printing technology, applied in the direction of fiber mechanical structure, grating fiber, cladding fiber, etc., can solve the problems of difficult adaptation and real-time monitoring of composite material structural parts, achieve simple manufacturing process, realize real-time health monitoring, The effect of easy layout process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

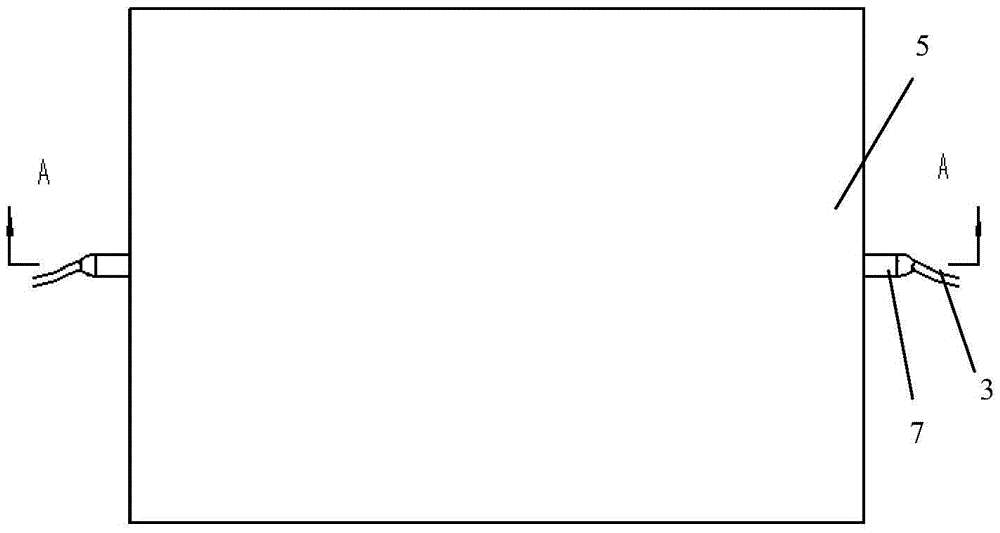

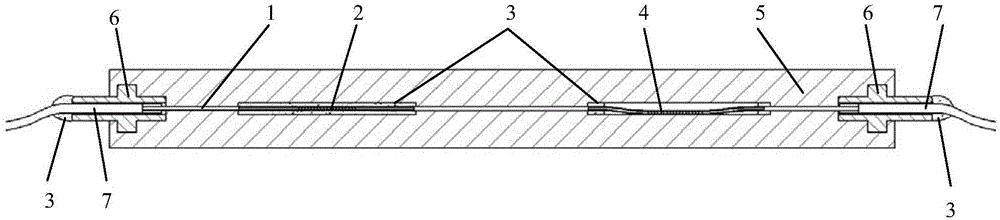

[0031] A 3D printing based fiber grating smart composite structure, such as figure 1 and figure 2 As shown, it includes a composite material matrix 5 and an optical fiber 1 located in the composite material matrix 5, the optical fiber 1 includes a grating and a signal transmission pigtail, and the signal transmission pigtail is drawn from the composite material matrix 5; the composite material matrix 5 is printed by 3D A part is produced by adding the optical fiber 1 and then continuing to 3D print the rest.

[0032] In this embodiment, the grating includes a strain measurement grating 2 and a temperature measurement grating 4, wherein the strain measurement grating 2 is integrally fixed after applying a pretightening force, and the two ends of the temperature measurement grating 4 are connected to the interior of the composite material matrix 5 in a relaxed state. Fixed, its fixing method is the adhesive 3 connection.

[0033] Preferably, the signal transmission pigtail is...

Embodiment 2

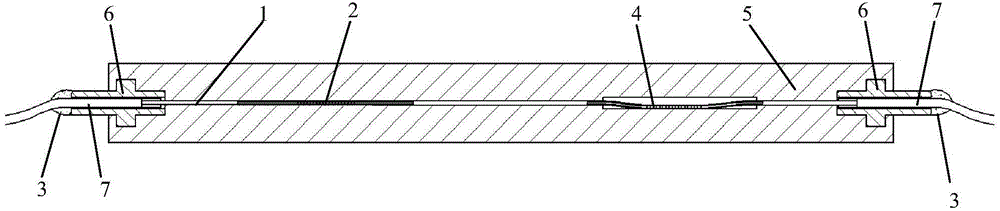

[0048] The structure and method of this embodiment are basically the same as those of Embodiment 1, the difference in structure is that the signal transmission pigtail 6 is covered with a fiber protection sleeve 7, and the fiber protection sleeve 7 and the strain measurement grating 2 are integrated , and both ends of the temperature measuring grating 4 are respectively fixed by fused deposition 3D printing of composite materials.

[0049] The method is different in that: the fiber protection sleeve 7 , the entirety of the strain measurement grating 2 , and both ends of the temperature measurement grating 4 are directly fixed by the composite material fused and deposited during the 3D printing process.

Embodiment 3

[0051]The structure and method of this embodiment are basically the same as those of Embodiment 1. The difference is that the structure of the composite material matrix itself is relatively complex, and the grating is a plurality of distributed gratings. Determined in places affected by high temperatures.

[0052] The traditional laminated composite material smart board embeds the fiber grating into the interlayer, fixes the fiber grating with an adhesive, and reinforces the composite material board through a lamination process. This method cannot ensure the installation position of the fiber grating. It is more free to control, and it is difficult to realize the intelligence of composite material parts with complex spatial structures. Using 3D printing technology, fiber gratings can be embedded in any position that needs to be detected in composite parts with complex spatial structures, so as to realize the health monitoring of complex structural parts of composite materials....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com