An automatic optical detection device and detection method thereof

An automatic optical inspection and component technology, which is applied in the direction of optical testing defects/defects, etc., can solve the problems that are difficult to adapt to dense and fine-pitch board testing tasks, uneconomical, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

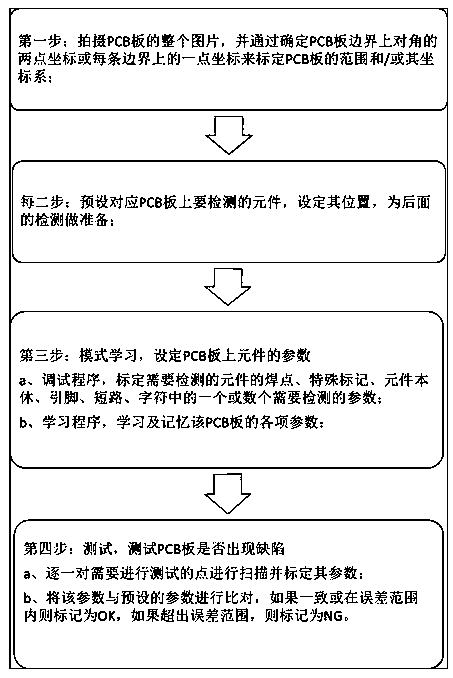

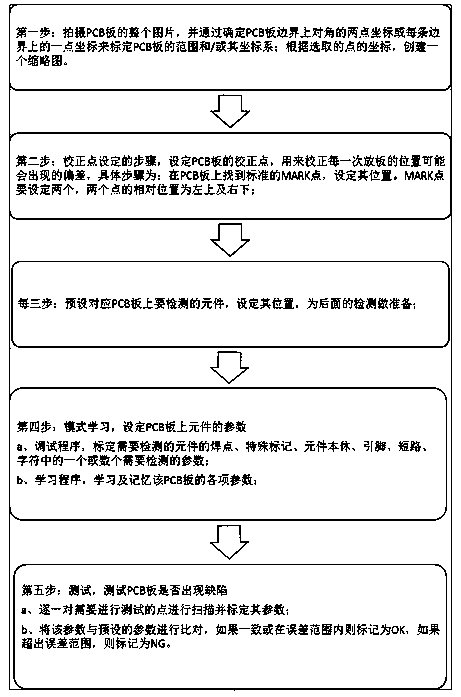

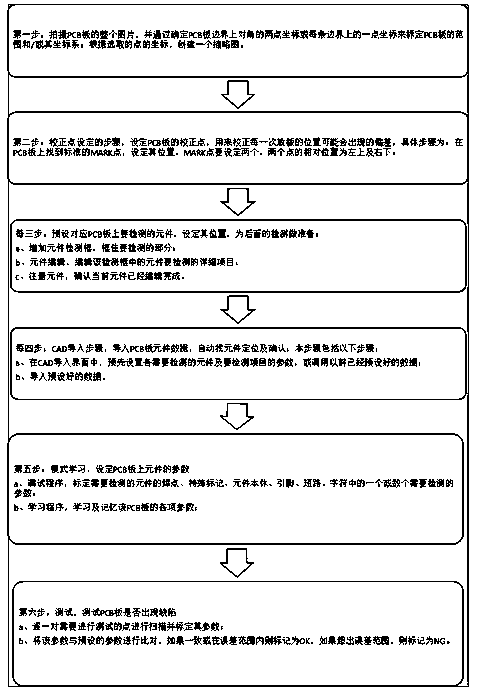

[0069] An automatic optical detection method provided by the present invention, some embodiments of which are as follows figure 1 shown, including the following steps:

[0070] Step 1: Take the entire picture of the PCB board, and demarcate the scope of the PCB board and / or its coordinate system by determining the coordinates of two points on the opposite corners of the PCB board boundary or one point on each boundary; Each point of the point leads to two straight lines perpendicular to each other, and these four straight lines intersect to form a rectangle, which is consistent with the size and shape of the PCB board. Similarly, if any point is selected on the four boundaries of the PCB board, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com