A capacitive tomography sensor with helical electrodes

A technology of electrical capacitance tomography and helical structure, which is applied in the direction of converting sensor output, using electric/magnetic devices to transfer sensing components, instruments, etc., can solve the problem of increasing post-processing time, increasing computer storage data capacity, and inability to accurately detect multiple Problems such as phase flow flow axial parameters, etc., achieve the effect of reducing the amount of post-processing calculations, uniform distribution of sensitive fields, and improving real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention provides a capacitance tomography sensor with a spiral structure electrode, the sensor includes a main body structure part and a capacitance measurement part. Be described below in conjunction with accompanying drawing.

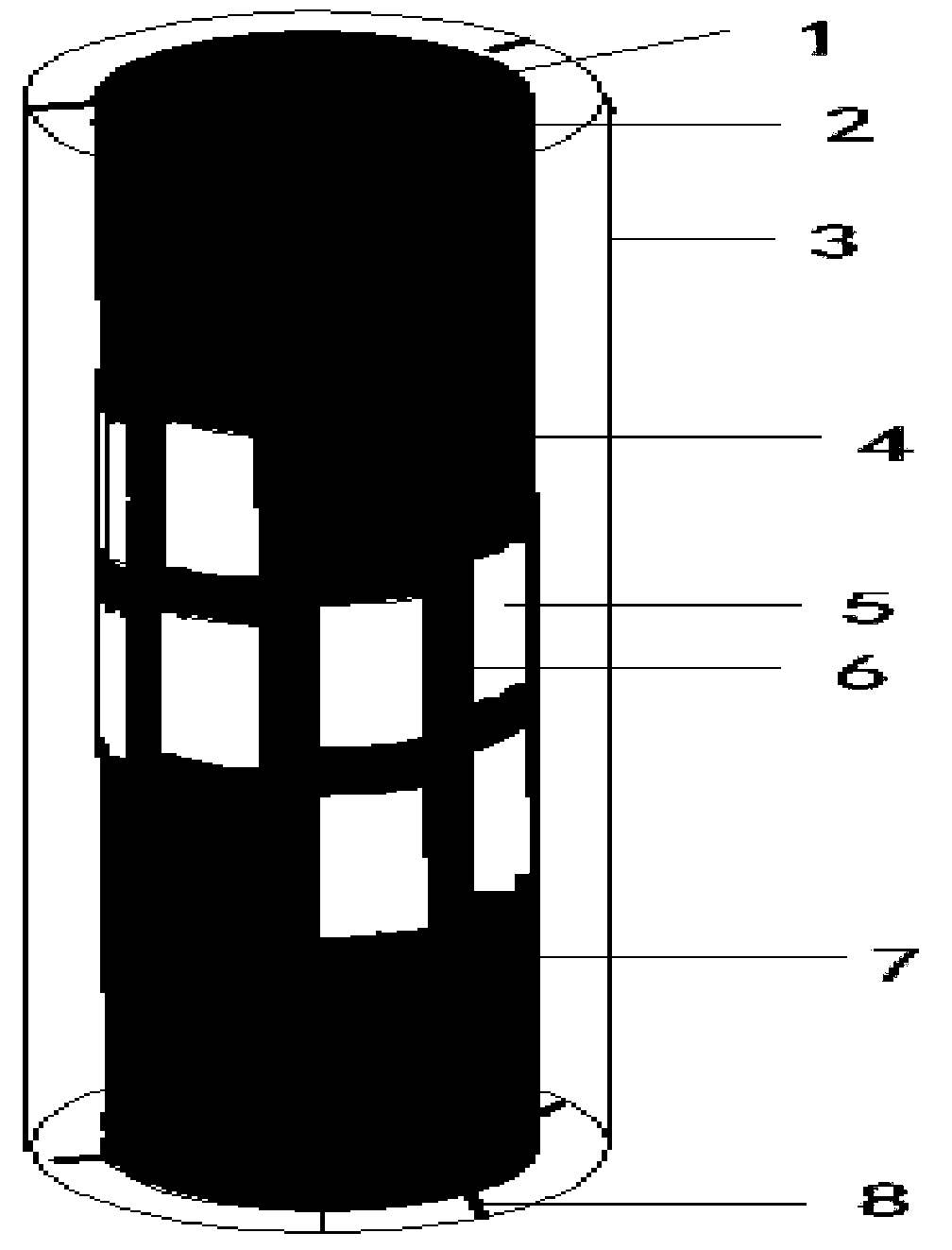

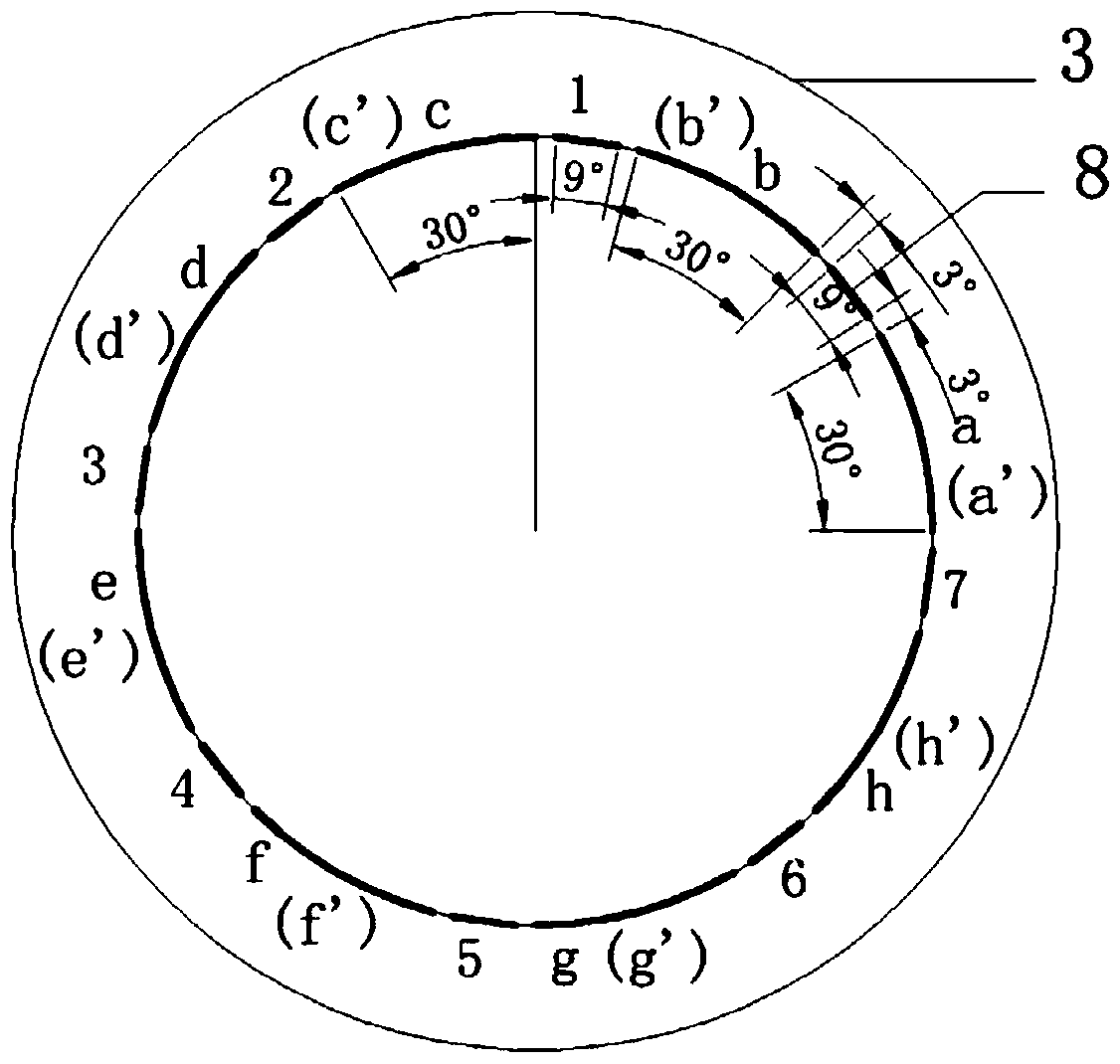

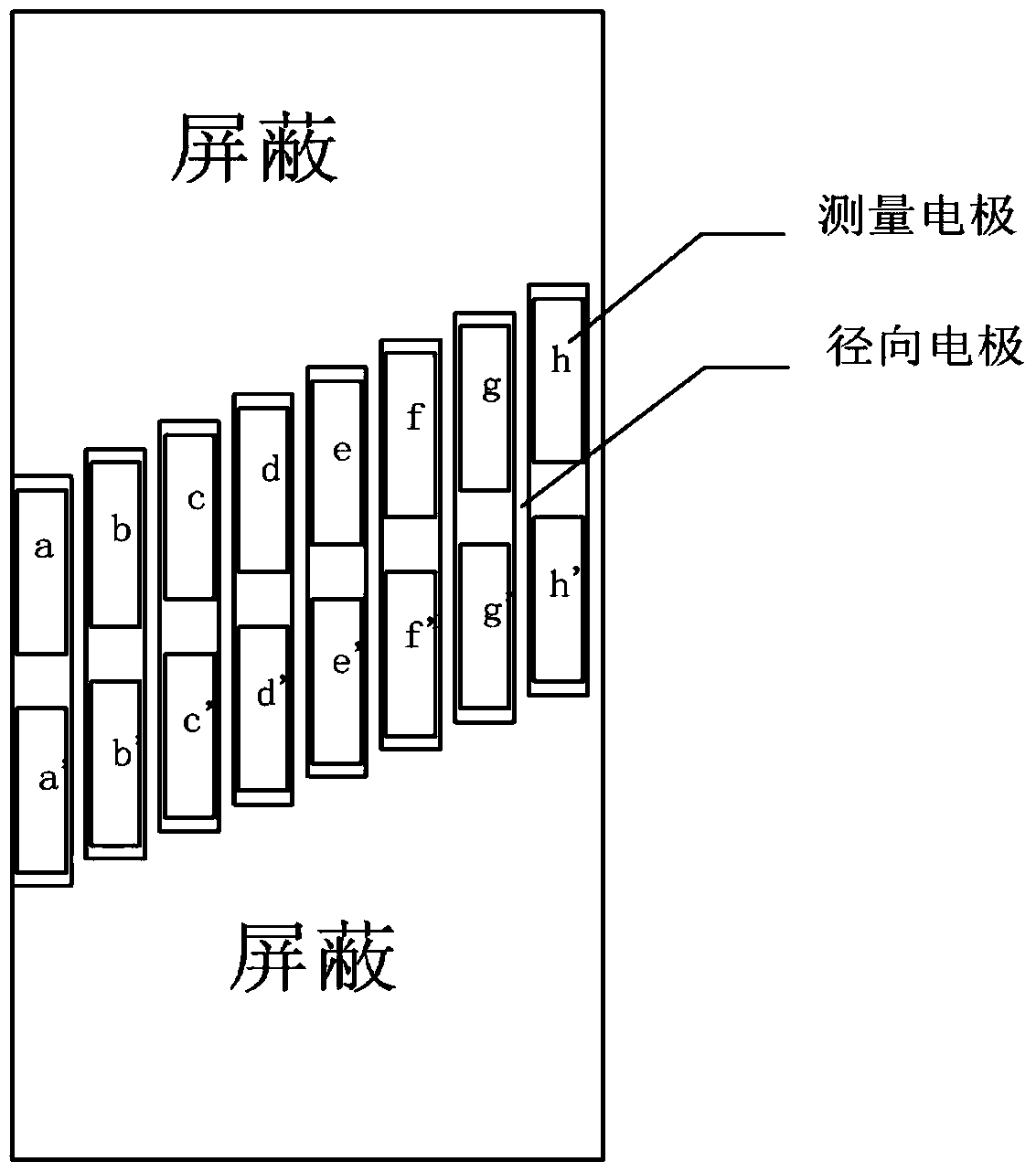

[0018] figure 1 Shown is a schematic diagram of the electrical capacitance tomography sensor structure. The main structure shown in the figure is composed of an insulating tube 1 and a fixed bracket 8. The circular space in the insulating tube is the measured space 2; the capacitance measurement part is to arrange radial electrodes 6 between the detection electrodes 5, and the detection electrodes 5 are in the form of Helically arranged on the outside of the insulating tube 1, divided into two circles, each circle has 8 electrodes, a total of 16 electrodes, rising continuously and evenly (such as image 3 shown). The electrode terminal shield is arranged at the upper and lower ends of the insulating tube 1, and the side close to the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com