Injection-molded instantaneous electric water heater with pressure adjusting function

A pressure regulation, electric water heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large difference in water inlet pressure, pressure explosion, and low possibility of non-metallic water tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

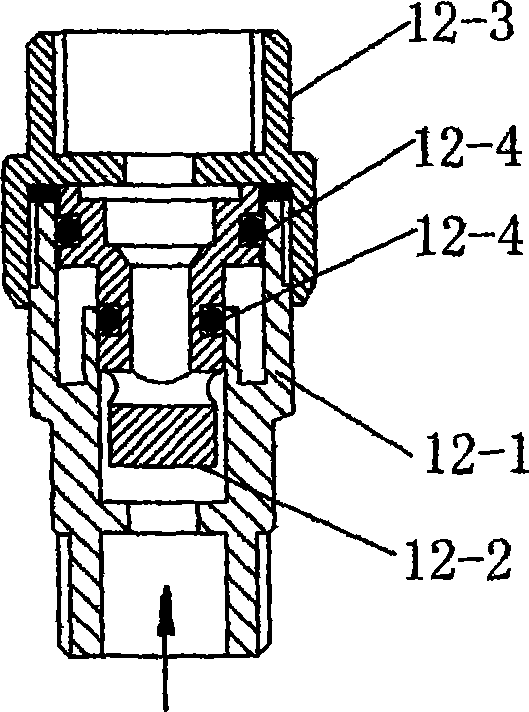

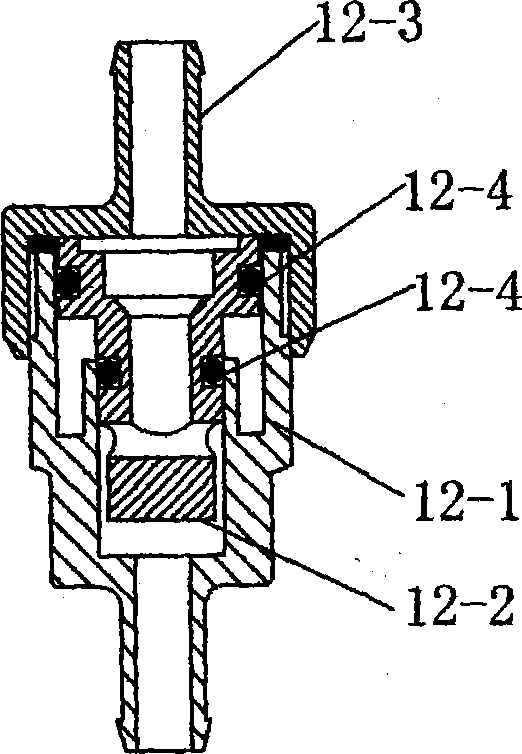

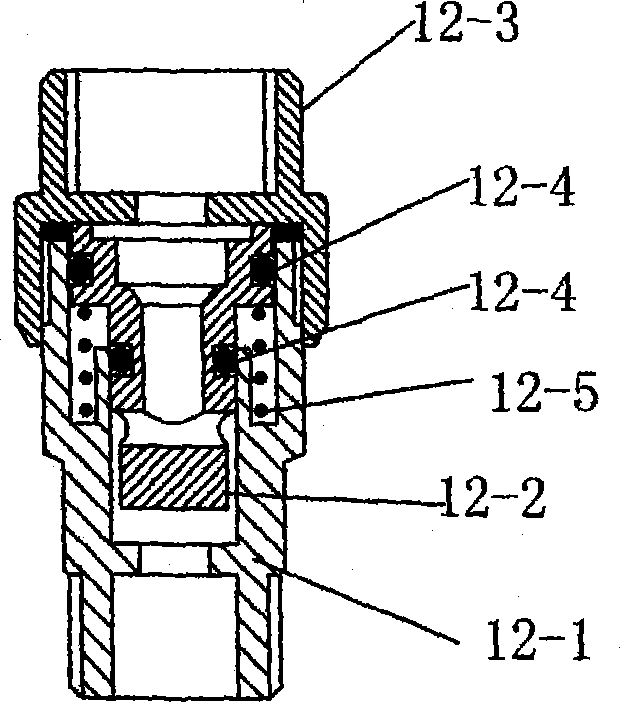

[0015] Attached below Figures 1 to 9 In the accompanying drawings: shell 1, cold water inlet pipe 2, hot water outlet pipe 3, water flow sensor 4, controller 5, electric heating pipe 6 (upper electric heating pipe 6-1, lower electric heating pipe 6-2) , outlet pipe fixed fulcrum 7, water tank 8, water nozzle 9, temperature measurement or temperature limit switch installation pipe 10, flange 11, pressure regulator 12, pressure relief valve 14, sewage outlet 15, water heating device 16 (airtight when water flows through Formula 6-1; semi-open formula 16-2).

[0016] Figure 1 to Figure 6 It is a pressure regulator with similar structure and similar function; only the connection method is different; Figure 3 to Figure 6 Among them, the spring 12-5 is added, and the pressure in the water tank can be set slightly higher, which is suitable for water tanks made of various materials.

[0017] Figure 7 to Figure 9 It is a structural schematic diagram of an electric water heater e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com