Two-section type pre-compression central arced curve blade profile structure

An arc-blade, pre-compression technology, applied in non-variable volume pumps, non-displacement pumps, components of pumping devices for elastic fluids, etc., can solve the problem of small flow capacity, insufficient pressurization capacity, Unable to meet the design requirements of high-load fan rotor blades and other problems, to achieve the effect of large flow capacity, strong supercharging capacity, and small lag angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

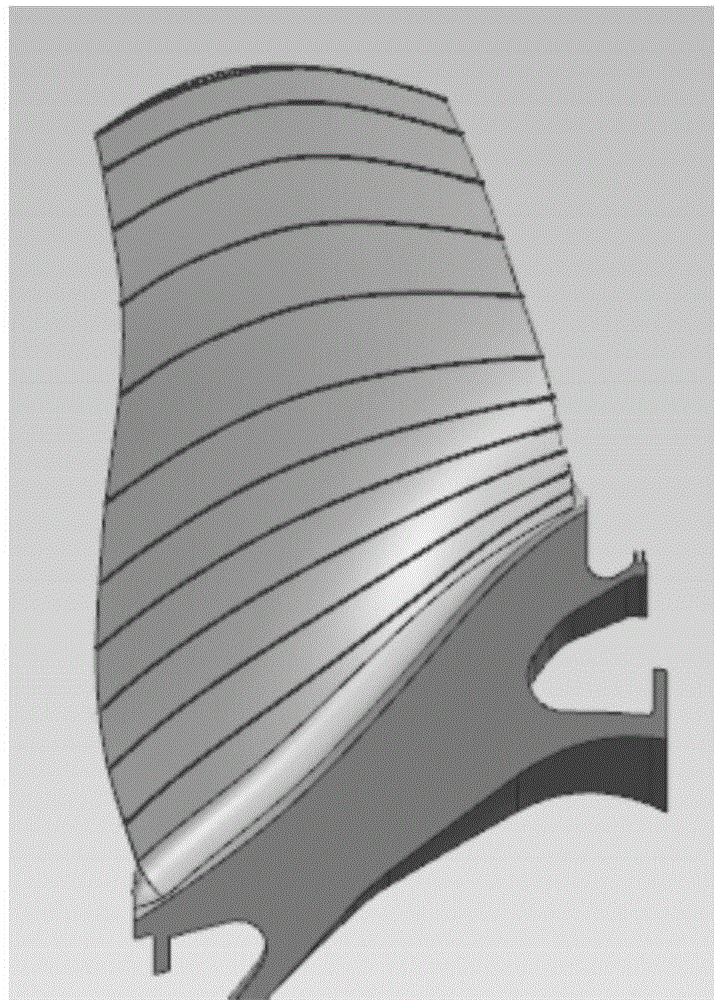

Embodiment 1

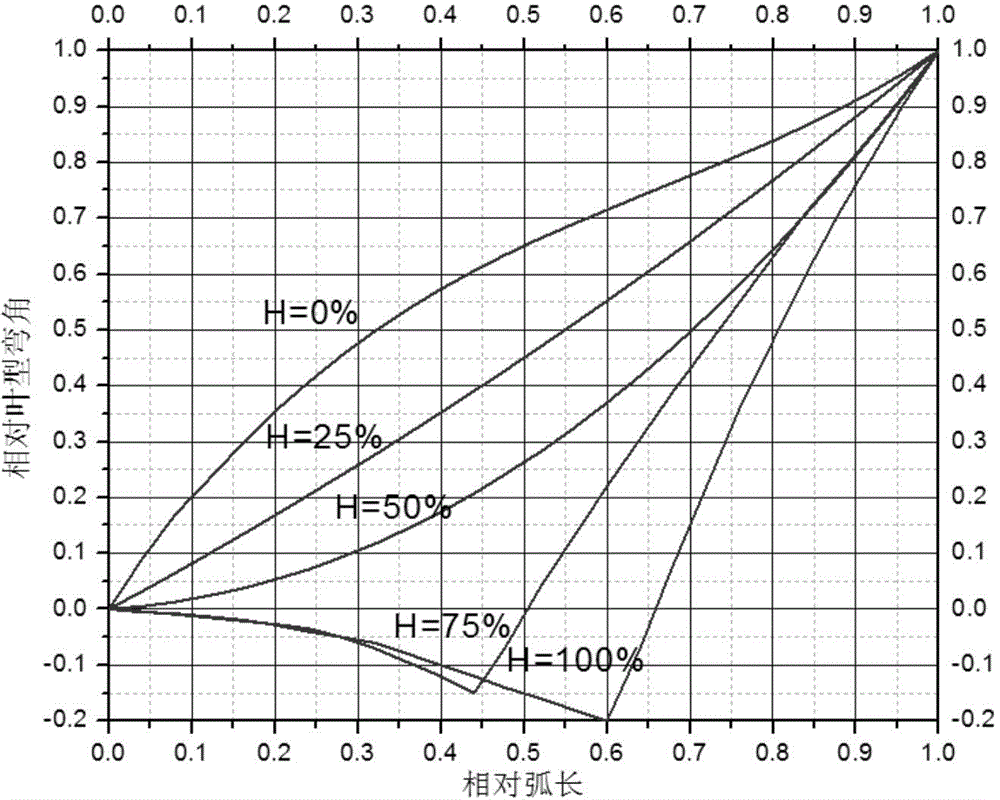

[0022] The invention provides a two-stage pre-compressed mid-arc airfoil structure, which is characterized in that: the two-stage pre-compressed mid-arc airfoil structure, the mid-arc airfoil is formed according to the difference of the inlet Mach number Two types, Ma = 0.8 ~ 1.2 across the range, the use of double-arc leaf type, the center line is a whole section of arc; The two arcs have the same slope at the transition point. When the Mach number exceeds 1.4, the shock loss is intensified, and the back and front of the blade are made into a concave shape to reduce the Mach number of the wave front, control the shock wave intensity, and reduce the shock wave loss. This blade shape is called a pre-compression blade shape.

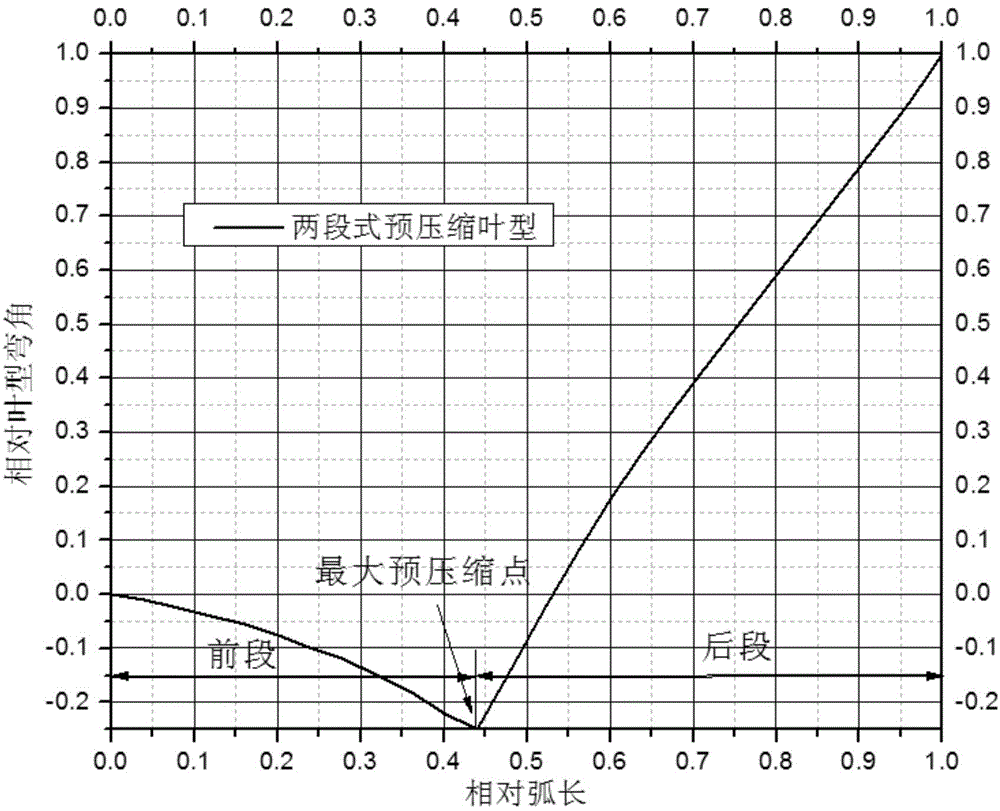

[0023] Taking the maximum pre-compression point of the relative bending angle of the airfoil as the dividing point, the middle arc is divided into front and rear sections, and the front and rear sections adopt different relative bending angle changes, refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com