Automatic temperature control methane fermentation device

A biogas fermentation and fermentation tank technology, applied in the field of automatic temperature-controlled biogas fermentation devices, can solve the problems of low production technology, easy to be affected by ambient temperature, and large differences in environmental factors, so as to achieve energy saving, stable biogas output and quality , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

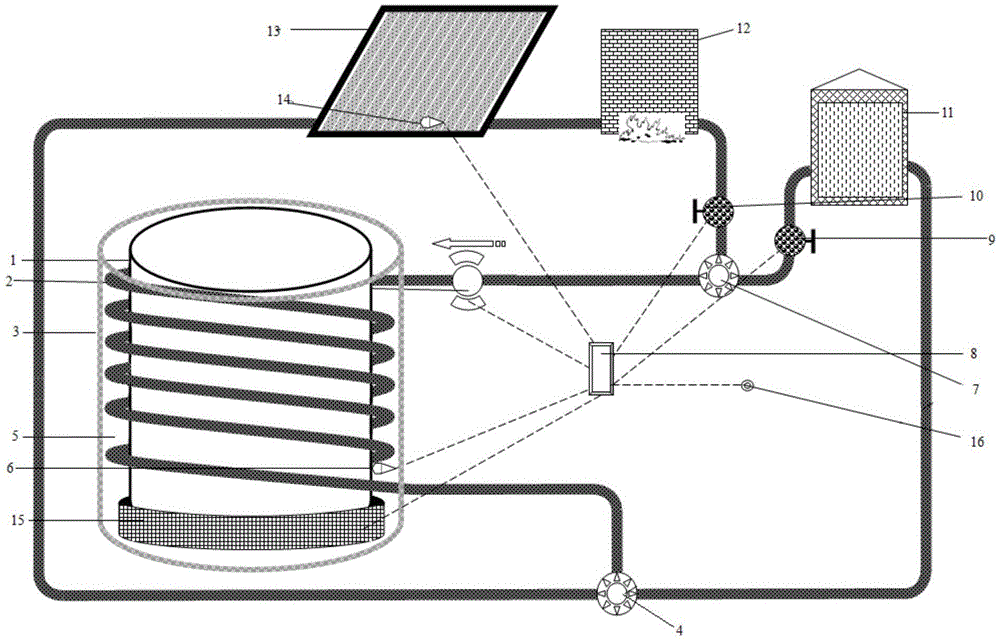

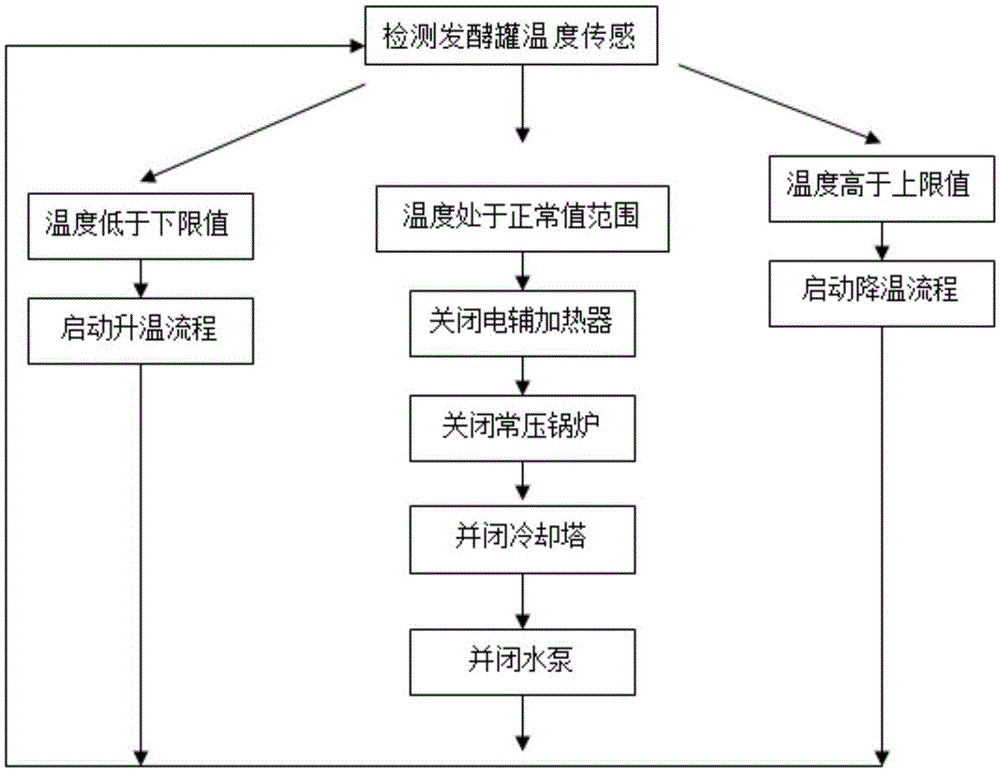

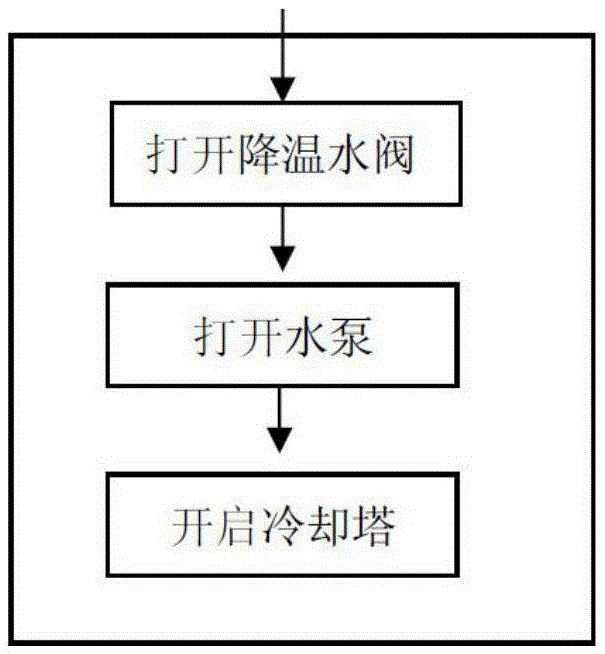

[0024] Such as Figure 1-4 As shown, an automatic temperature control biogas fermentation device includes a fermenter 1, a housing 3, a heat exchange tube 2, a heating system, a cooling system, a first temperature sensor 6, a control template 8 and a biogas pressure probe; the housing 3 is set A cavity structure is formed on the periphery of the fermentation tank 1, and the cavity part is the middle hot water layer 5; the heat exchange tube 2 is spirally wound on the outer wall of the fermentation tank 1 from top to bottom, and both ends of the heat exchange tube 2 are connected with the heating system and the cooling system Connected to form a circuit; the upper and lower heat exchange pipes 2 and the heating system and cooling system are respectively provided with a first water pipe collection hub 7, a second water pipe collection hub 4, and a connection between the fermentation tank 1 and the first water pipe collection hub 7 A water pump is provided on the heat exchange pi...

Embodiment 2

[0028] It is basically the same as Embodiment 1, except that the heating system is an atmospheric boiler 12, one end of the water tank of the atmospheric boiler 12 is connected to the first water pipe collection hub 7, and the other end is connected to the second water pipe collection hub 4; the first temperature There are more than 3 sensors 6, which are evenly arranged on the outer wall, middle and lower part of the fermenter 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com