Packaging barrel supply mechanism of automatic punching packaging production line

A packaging production line and packaging tube technology, applied in packaging and other directions, can solve the problems of low production efficiency and high labor costs, and achieve the effect of reliable work performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

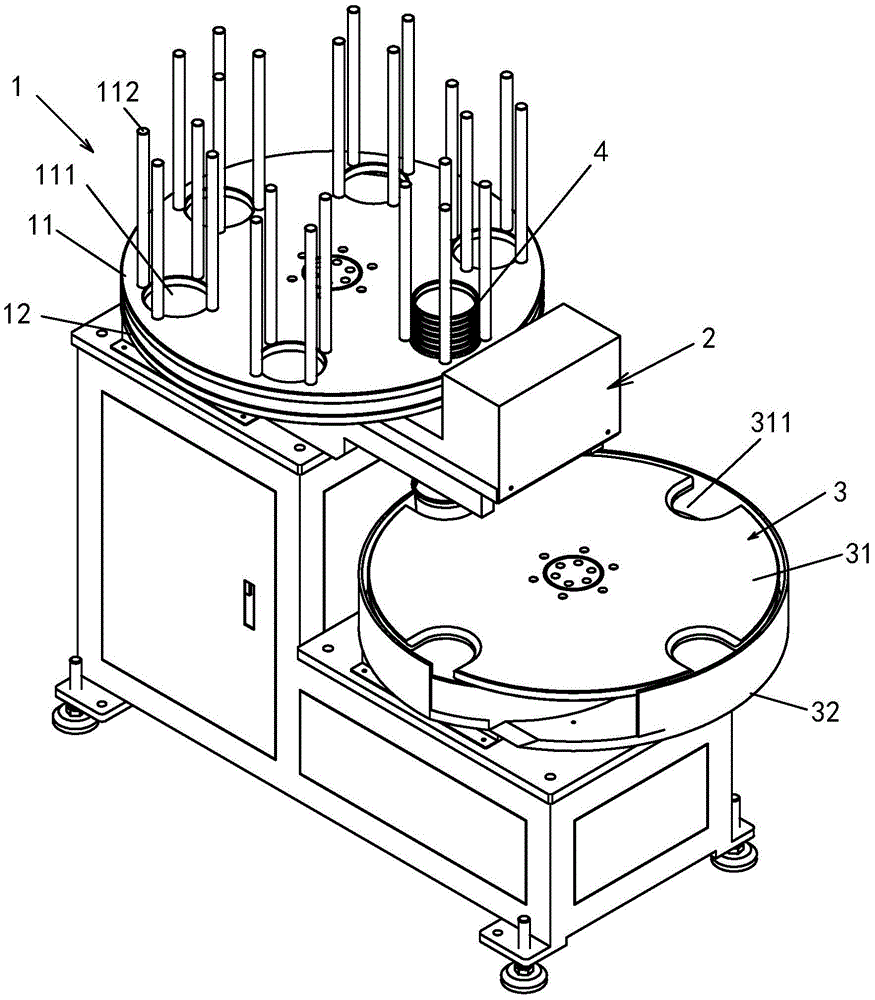

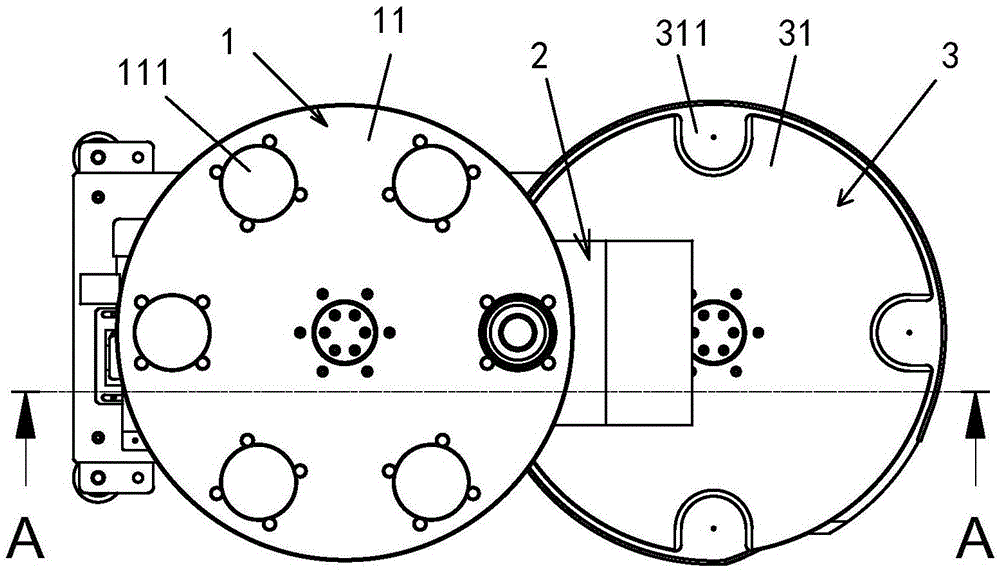

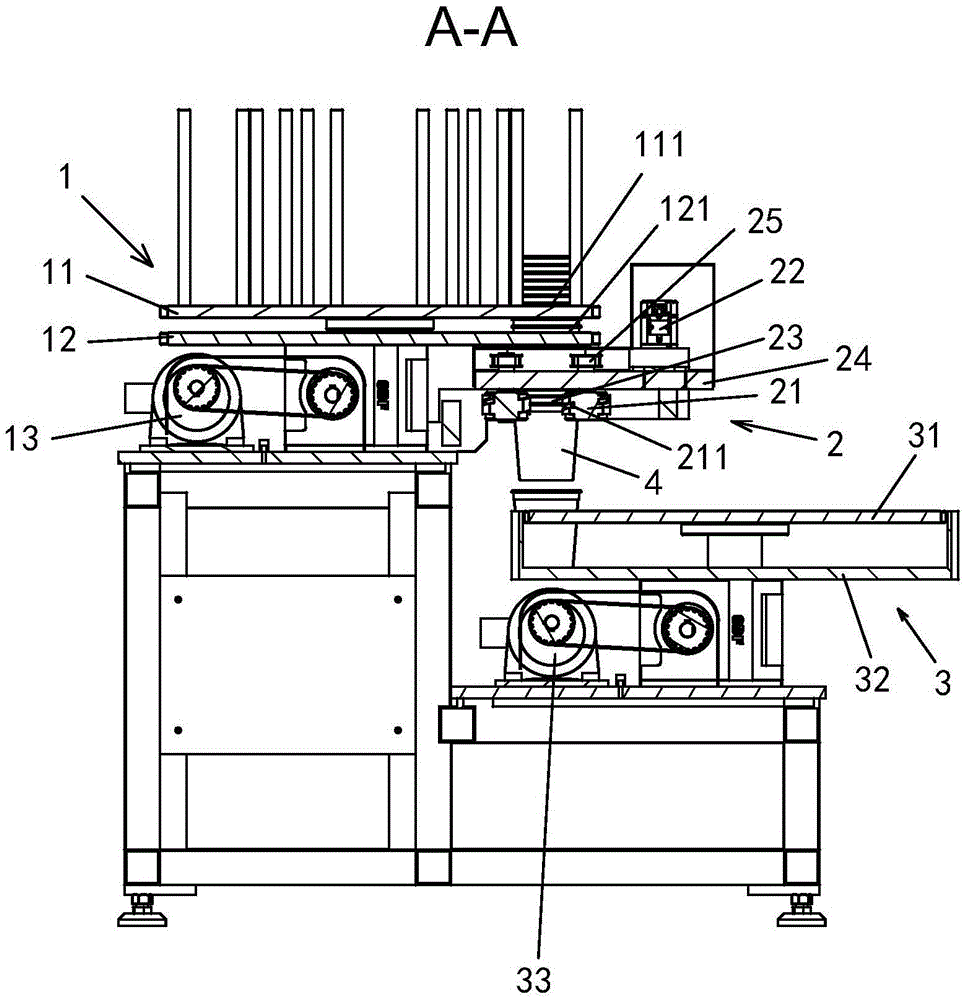

[0018] Example: see Figure 1-4 Shown:

[0019] A packaging cylinder supply mechanism of an automatic punching and packaging production line, which is composed of a cylinder storage turntable mechanism 1 , a cylinder separating mechanism 2 and a cylinder delivery turntable mechanism 3 .

[0020] see Figure 1-4 As shown, the storage cylinder turntable mechanism 1 includes a storage cylinder turntable 11 , a fixed bottom plate 12 and a storage cylinder driving device 13 for driving the storage cylinder turntable 11 to rotate. The storage cylinder turntable 11 is arranged horizontally with the surface of the disk, the fixed bottom plate 12 is lined under the storage cylinder turntable 11, and the storage cylinder turntable 11 is rotatably supported relative to the fixed bottom plate 12; the fixed bottom plate 12 is provided with a lower cylinder through hole 121, The storage cylinder rotating disk 11 is correspondingly provided with a plurality of storage cylinder through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com