A bogie forced guiding mechanism

A guiding mechanism and frame technology, which is applied in the design and manufacture of rolling stock bogies, and in the field of rolling stock structure design, can solve problems such as difficult installation of forced guiding mechanisms, increase adhesion utilization, reduce wear, and save manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

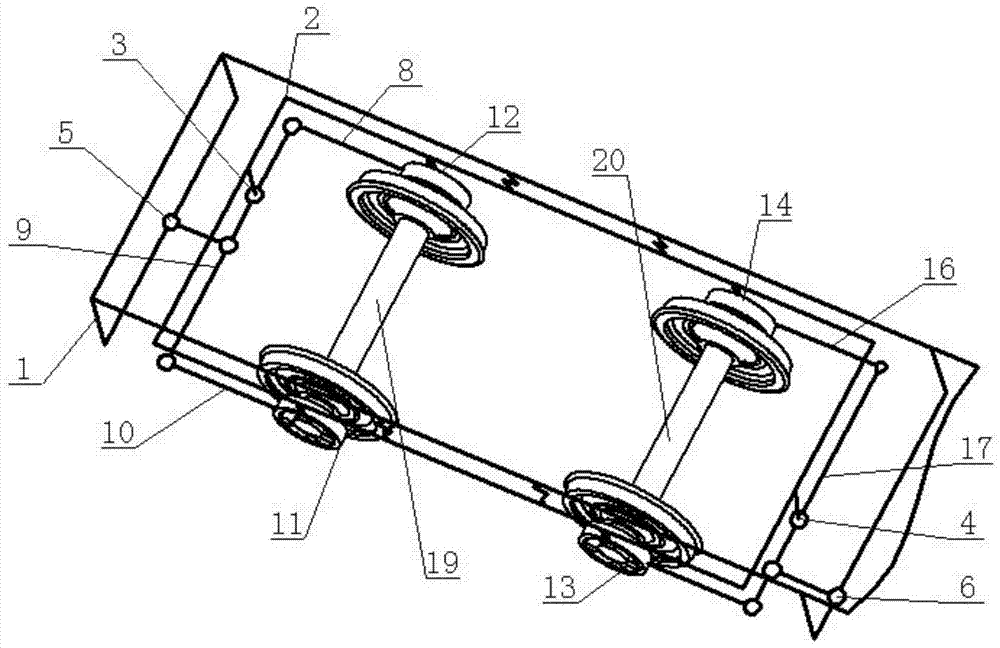

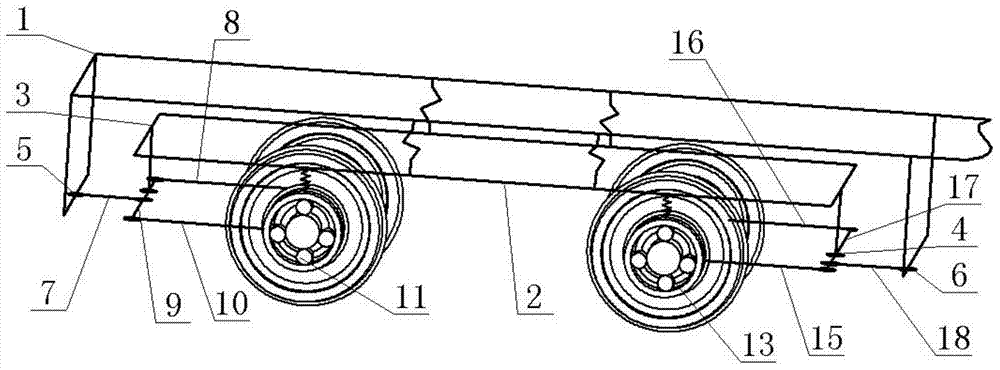

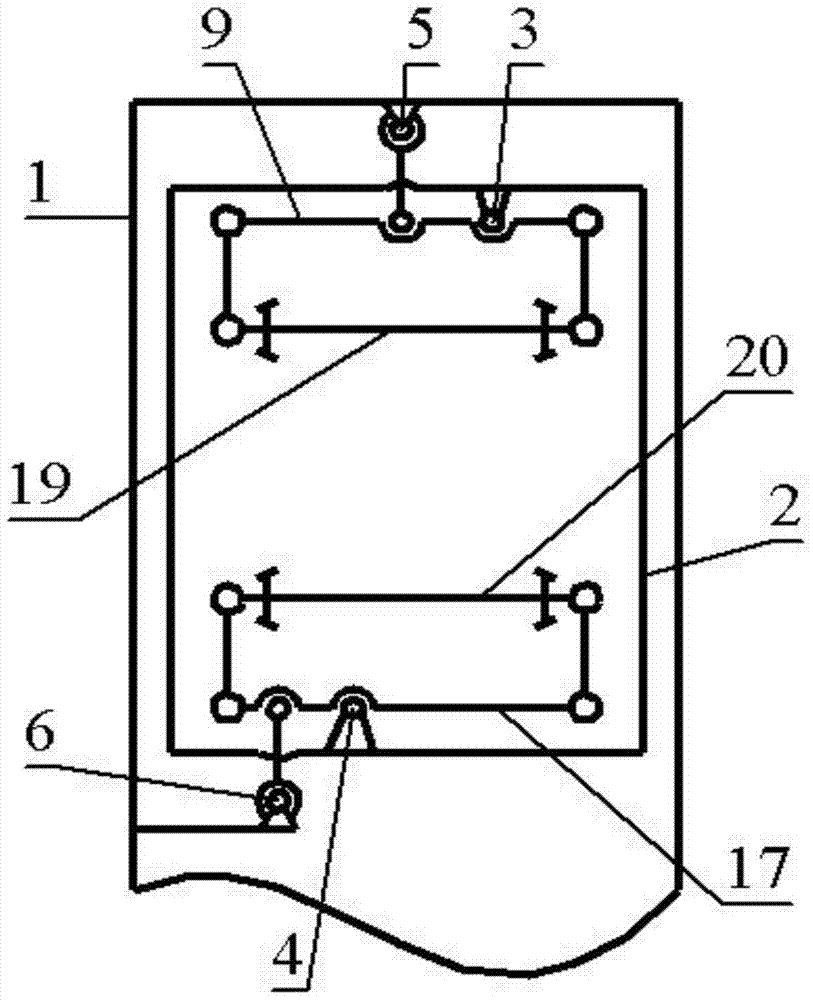

[0021] A bogie force guide mechanism, including a frame 2 supporting the car body 1, a left front axle box 11 and a right front axle box 12 are correspondingly provided at the left and right ends of the front axle 19 wheel sets, and a left front axle box 12 is correspondingly provided at the left and right ends of the front beam 9. Tie rod 10, right front tie rod 8, one end of left front tie rod 10 is hinged to left front axle box 11, the other end is hinged to left end of front crossbeam 9, one end of right front tie rod 8 is hinged to right front axlebox 12, the other end is hinged to front crossbeam 9 right end; rear axle 20 The left and right ends of the wheel pair are correspondingly provided with a left rear axle box 13 and a right rear axle box 14, and the left and right ends of the rear beam 17 are correspondingly provided with a left rear tie rod 15 and a right rear tie rod 16, and one end of the left rear tie rod 15 is connected to the left rear axle. The box 13 is hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com