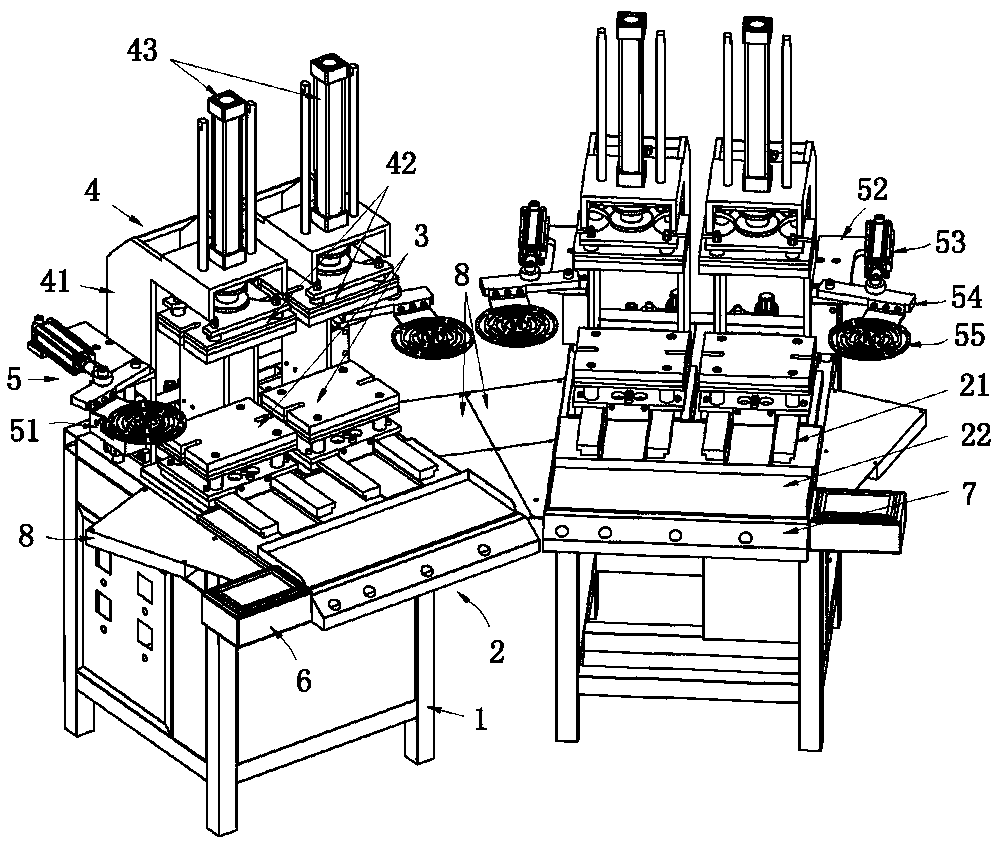

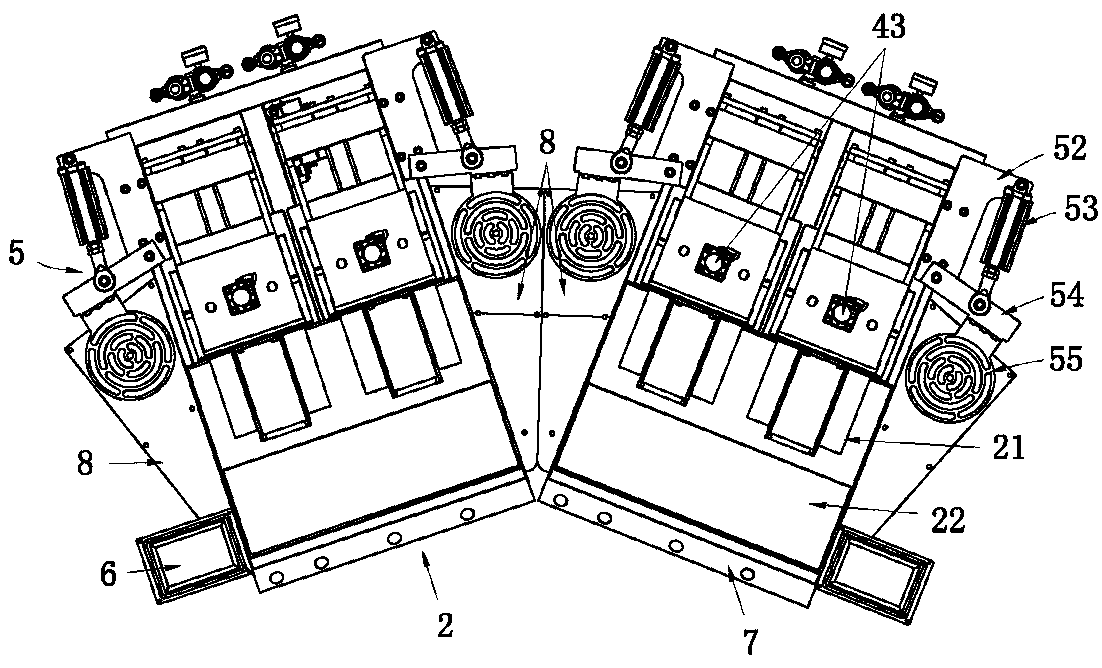

Multi-head semi-automatic setting machine

A semi-automatic, setting machine technology, used in home appliances, other home appliances, household components, etc., can solve the problems of uncontrollable product quality consistency, operator's hand burns, operator's labor intensity, etc., to achieve the design Ingenious, easy to adjust the mold, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0022] The fluid transmission system of the present invention refers specifically to the pneumatic system. The horizontal actuators (not shown in the figure), vertical actuators, lifting actuators and swing arm actuators appearing in this embodiment are all cylinders, which are respectively connected with the pneumatic system. Air compressor connection.

[0023] The motion trajectory of the end tool of the pick-and-place device in the present invention is to swing from above the corresponding lower mold to the corresponding automatic pick-and-place area; the lift actuator and the swing arm actuator of the pick-and-place device are used to drive the end tool Realize the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com