Clamping apparatus of variable-pitch flexible robot

A fixture and flexible technology, applied in the field of tool fixtures, can solve the problems of low work efficiency, time-consuming and labor-intensive, limited suction range of ice cream, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

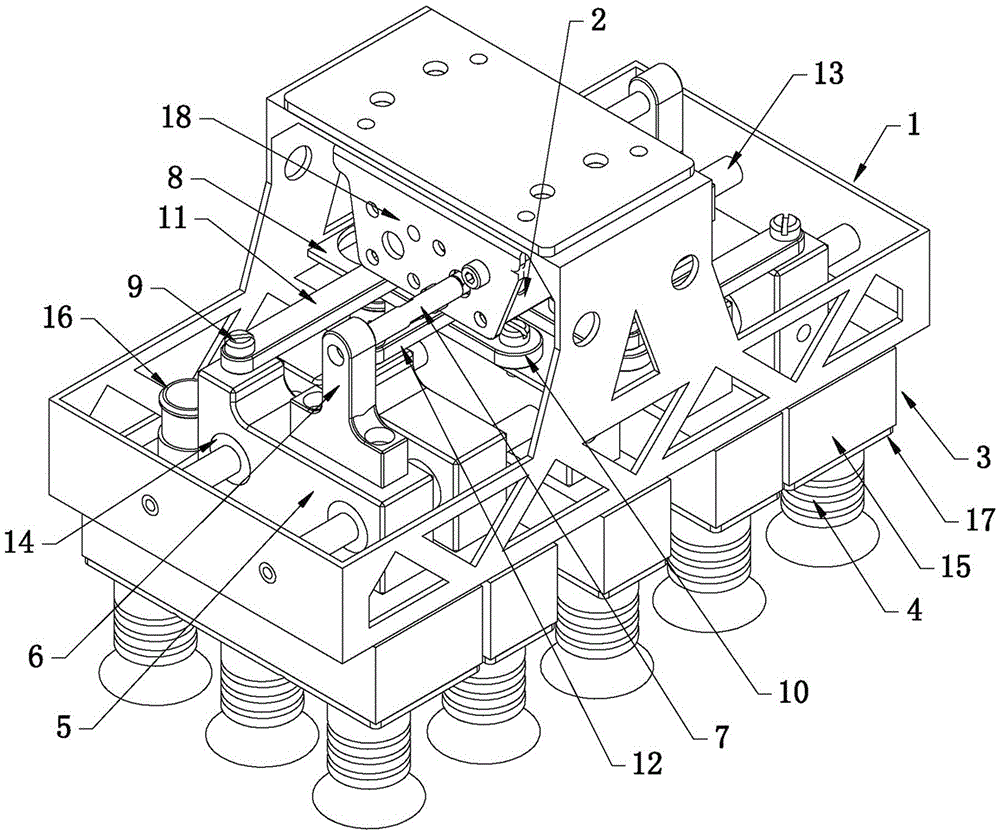

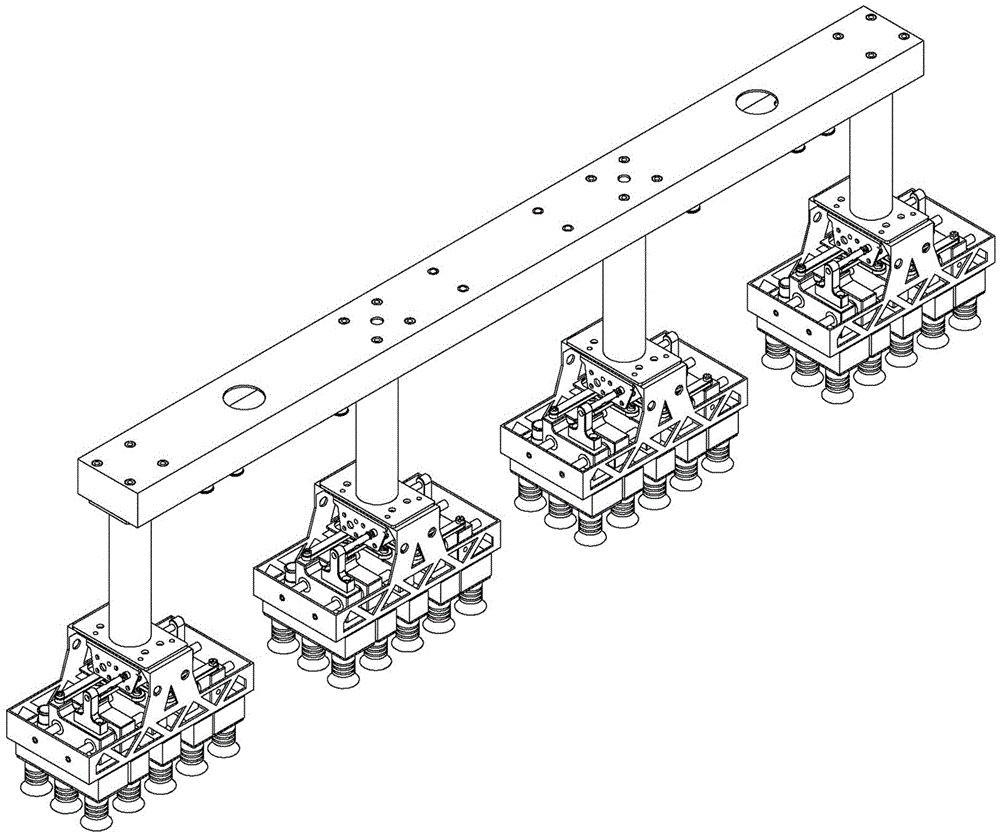

[0020] Such as figure 1 As shown, five suction cups 3 are arranged in the jig frame 1 of the pitch-variable flexible robot jig of the present invention, and three suction cup soft joints 4 are arranged on the cavity cover plate 17 of each suction cup 3. 1 is provided with two guide rods 13, and five suction cups 3 are all installed on the guide rods 13 through the connecting block 5, wherein the middle suction cup 3 is fixedly arranged under the frame positioning plate 8 and does not move along the fixture frame 1. The connecting block 5 located at both ends of the fixture frame 1 in the length direction is fixed with a cylinder push block 6, and the cylinder push block 6 is connected with the piston rod of the corresponding cylinder 2 through the corresponding cylinder connecting rod 7, and has a cylinder The connecting block 5 of the push block 6 is connected with the corresponding main connecting rod 10 arranged on the frame positioning plate 8 through the active support co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com