Forklift portal double-face welding device

A technology of double-sided welding and forklift gantry, applied in the field of forklifts, can solve the problems of poor welding effect, difficult welding positioning and high cost, and achieve the effect of improving welding effect and welding efficiency and solving welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the technical solution of the present invention will be described in detail through specific examples.

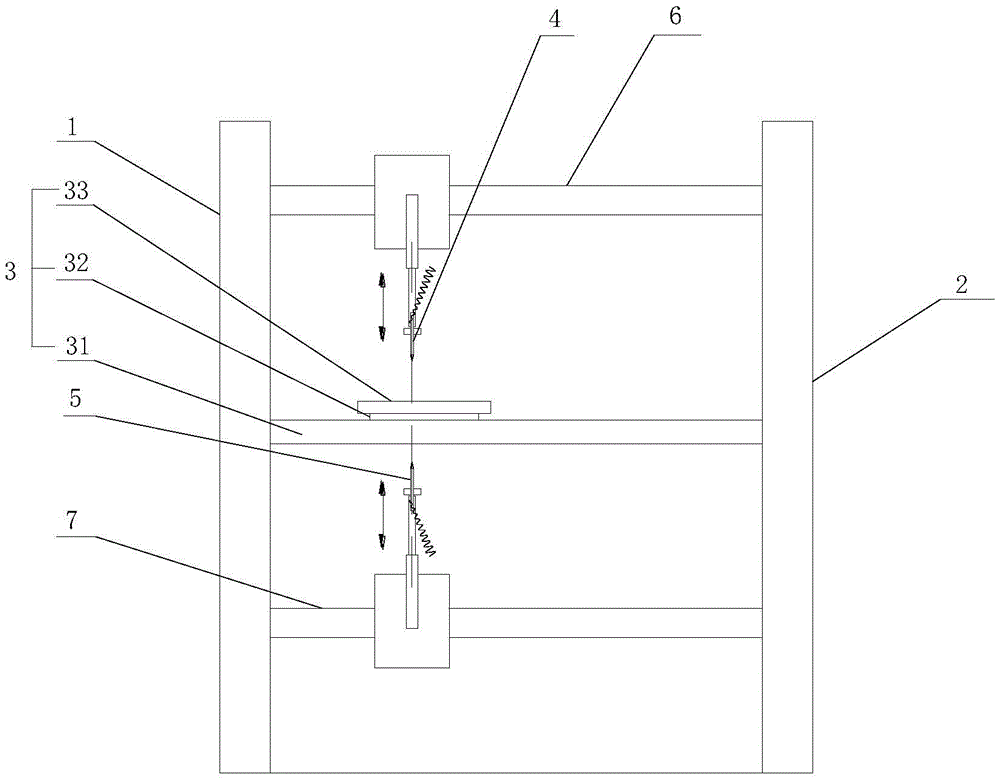

[0023] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a double-sided welding device for a forklift mast proposed by the present invention.

[0024] refer to figure 1 , a double-sided welding device for a forklift mast proposed by an embodiment of the present invention, comprising: a first side frame 1, a second side frame 2, a workpiece fixing frame 3, a first welding mechanism 4, a second welding mechanism 5, a first A drive mechanism and a second drive mechanism, wherein:

[0025] The first side frame 1 and the second side frame 2 are opposite and arranged at intervals, and the workpiece fixing frame 3 is located between the first side frame 1 and the second side frame 2 and connected with the first side frame 1 and the second side frame 2 respectively; Workpiece fixed frame 3 comprises underframe 31, slide frame 32 and slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com