Preparation method of modified starch styptic powder

A technology of hemostatic powder and starch, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of local heat release, non-degradable, easy allergies, etc., and achieve the effect of improving production efficiency and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

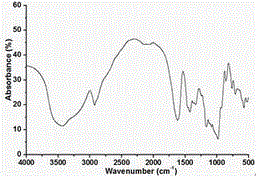

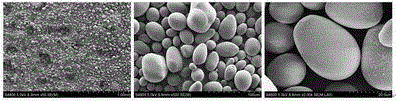

Image

Examples

Embodiment 1

[0019] Dissolve starch with a molecular weight of 5000 in water to prepare a solution with a mass concentration of 10%, gelatinize at 30°C for 200 minutes at a stirring speed of 100 rpm, and add starch with a mass ratio of 10:1 after the solution is uniformly mixed. Combined agent sodium trimetaphosphate, after continuing to stir for 5 hours, carry out spray drying, the air velocity of spray drying is 50 liters / minute, and gas temperature is 100 ℃. The spray-dried modified starch granules are collected to obtain hemostatic powder microspheres, and the particle diameter of the microspheres is 50-300 microns.

Embodiment 2

[0021] Dissolve starch with a molecular weight of 100,000 in water to make a solution with a mass concentration of 3%, gelatinize at 70°C for 100 minutes at a stirring speed of 6000rpm, and add starch with a mass ratio of 50:1 after the solution is evenly mixed. The cross-linking agent sodium hexametaphosphate was continued to be stirred for 3 hours and then spray-dried. The air velocity of the spray-dried air was 100 liters / minute, and the gas temperature was 150° C. The spray-dried modified starch granules are collected to obtain hemostatic powder microspheres, and the particle diameter of the microspheres is 5-100 microns.

Embodiment 3

[0023] Dissolve starch with a molecular weight of 3 million in water to make a solution with a mass concentration of 0.01%, gelatinize at 100°C for 10 minutes at a stirring speed of 3000rpm, and add starch with a mass ratio of 100:1 after the solution is evenly mixed. Cross-linking agent sodium trimetaphosphate, after continuing to stir for 0.5 hours, carry out spray drying, the air velocity of spray drying is 80 liters / minute, and gas temperature is 50 ℃. The spray-dried modified starch granules are collected to obtain hemostatic powder microspheres, and the particle diameter of the microspheres is 20-80 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com