Motor core pulling maintenance platform

A maintenance platform and platform technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of increasing the cost of motor inspection and maintenance, reducing the efficiency of motor inspection and maintenance, and occupying the utilization rate of driving, so as to achieve fast and convenient core-pulling operations and improve maintenance efficiency , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

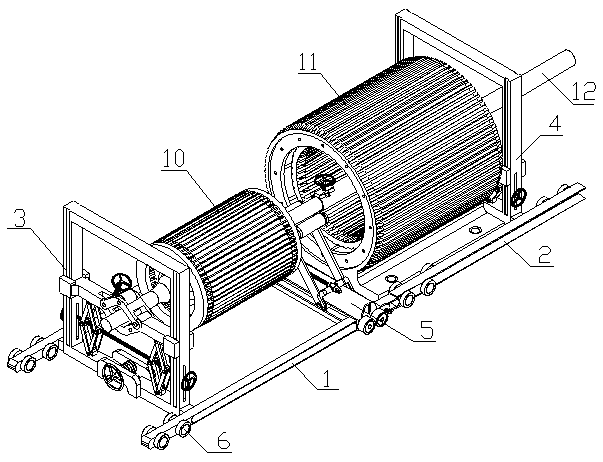

[0017] Such as figure 1 As shown, the motor core-pulling maintenance platform of the present invention includes a front section double guide rail 1, a rear section double guide rail 2, a front mobile trolley 3, a rear mobile trolley 4 and a pallet trolley 5, and the front section double guide rail 1 and the rear section double guide rail 2 are inlaid sleeve connection, and rollers 6 are provided at both ends;

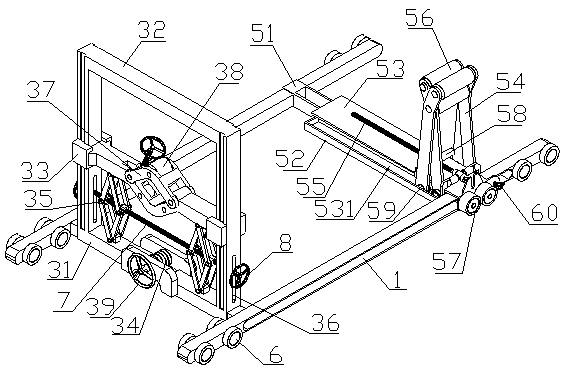

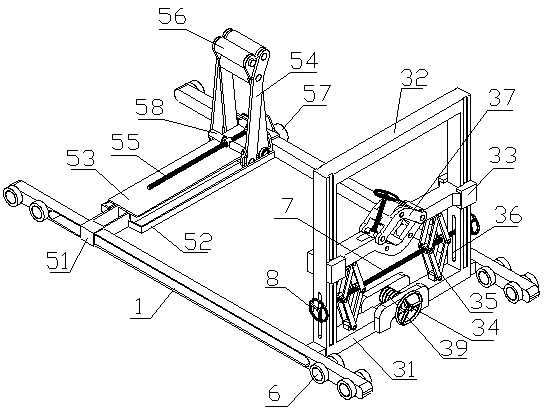

[0018] Such as figure 2 and image 3 As shown, the front mobile trolley 3 includes a first bottom beam 31, a first door frame 32, a first lifting beam 33, a first worm gear transmission mechanism 34 and a first lifting mechanism 35, and the first bottom beam 31 It is horizontally arranged at the front end of the front double guide rail 1, and the first worm gear transmission mechanism 34 is arranged in the middle of the first bottom beam 31 and drives the front double guide rail 1 to move through the first hand wheel 39. The first The door-shaped frame 32 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com