Junction box and junction box assembly

A junction box and box body technology, applied in the direction of connection, electrical components, conductive connection, etc., can solve the problems of inconvenient use, complex overall structure, increased working hours, etc., and achieve the effects of convenient use, simplified installation structure, and simplified installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

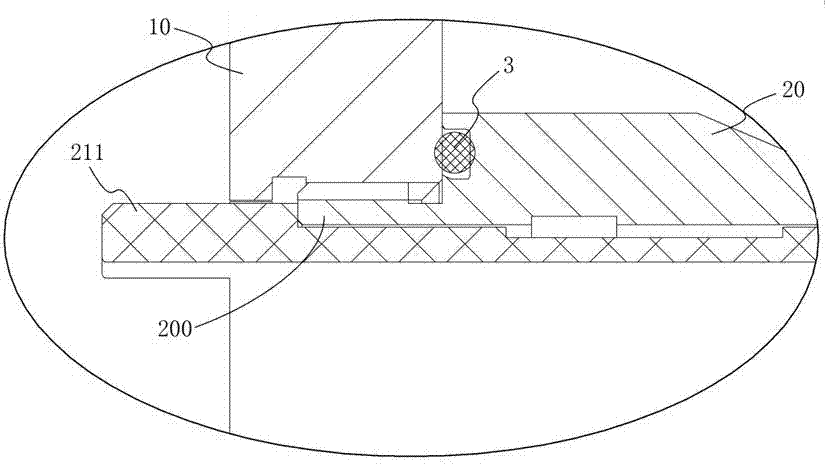

[0012] Embodiment one of the junction box assembly of the present invention: as Figure 1-3 As shown, it includes a junction box 1 and a connector 2 installed on the junction box 1 . The junction box 1 includes a box body, and the box body includes a mounting panel 10 , and the mounting panel 10 is provided with mounting holes through which the connector 2 is installed. For ease of description, the front end of the connector is defined as the plug-in end, and the side of the mounting panel facing the connector is the front side.

[0013] The connector 2 includes a connector housing 21 and a connecting nut 20 that is rotatably sleeved on the outside of the connector housing 21. The front end of the connector housing 21 is provided with a housing anti-rotation structure, and the front end of the connecting nut 20 is provided with an outer Thread segment 200. The inner hole wall of the mounting hole is sequentially provided with an internal thread section for screwing with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com