Well resistor structure and manufacturing method thereof and silicon device on insulator

A manufacturing method and well resistance technology, which is applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid-state devices, etc., can solve the problems of large lateral diffusion and difficulty in obtaining resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

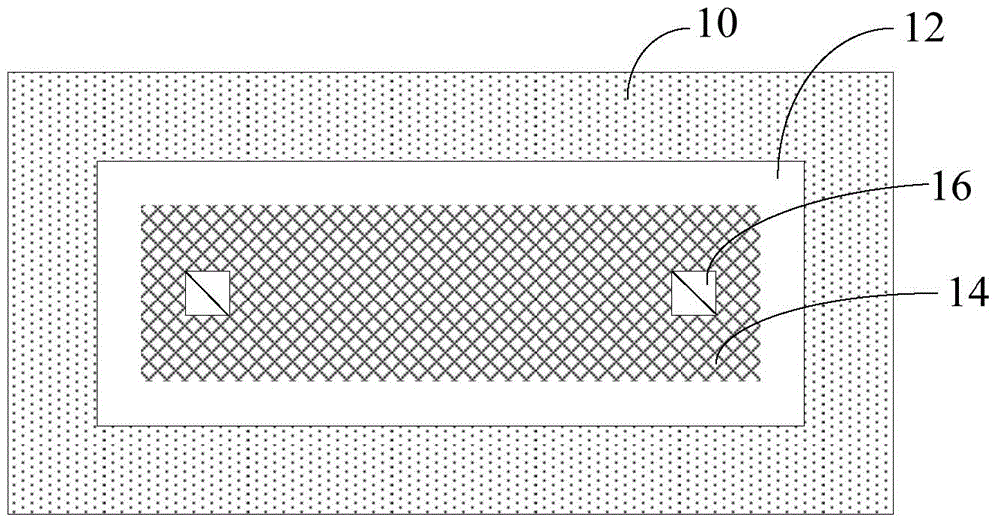

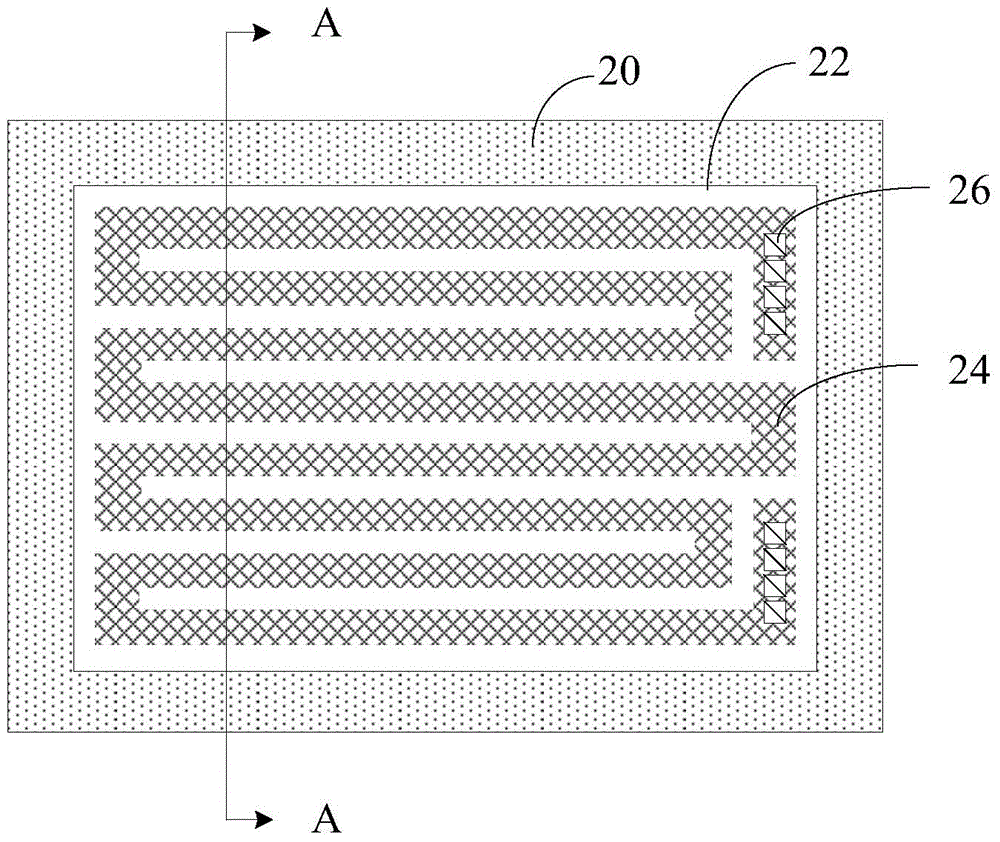

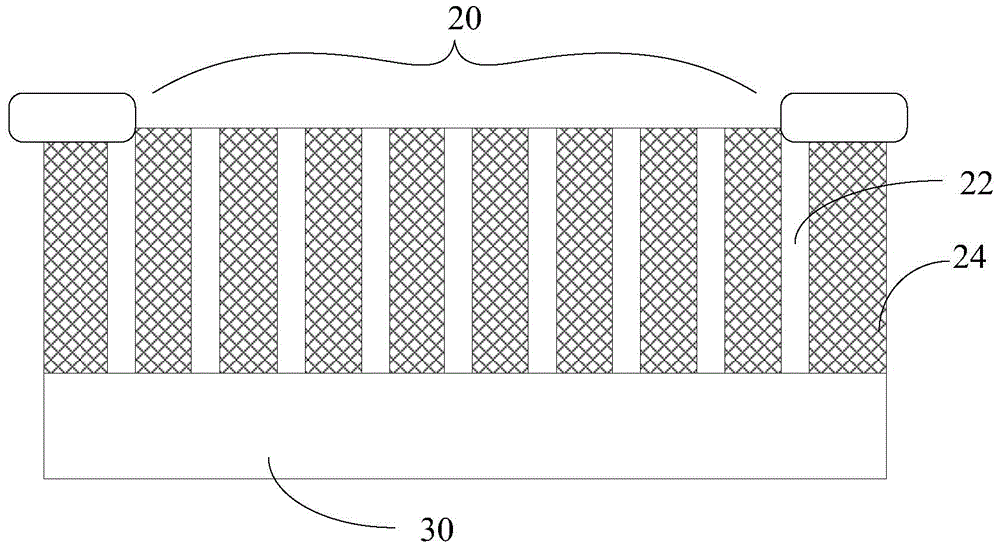

[0023] figure 1 It is a top view of the well resistor structure in an embodiment. Including insulation ( figure 1 not shown) and the active region 10 on the insulating layer. The active region 10 includes a well region 14 and a trench isolation structure 12 extending down to the insulating layer. The trench isolation structure 12 surrounds the well region 14 laterally and separates the well region 14 vertically. That is to say, the depth of the trench isolation structure 12 must be at least the same as that of the well region 14 , so that the well region 14 cannot extend laterally beyond the trench isolation structure 12 at the position where the trench isolation structure 12 is disposed. The cross section of the well region 14 is elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com