Travelling crane positioning control system and control method

A positioning control and controller technology, applied in two-dimensional position/channel control, control drive, electric vehicles, etc., can solve the problem of high labor cost, achieve the effects of reduced labor cost, high stability, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

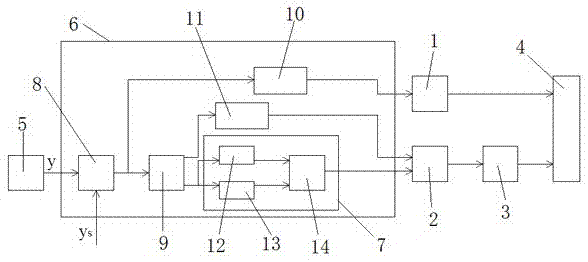

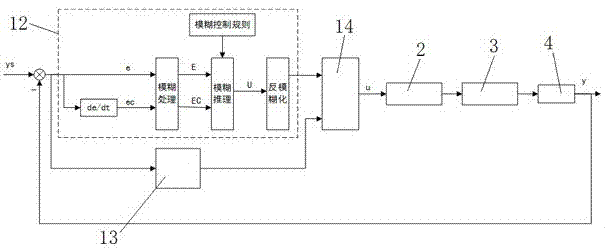

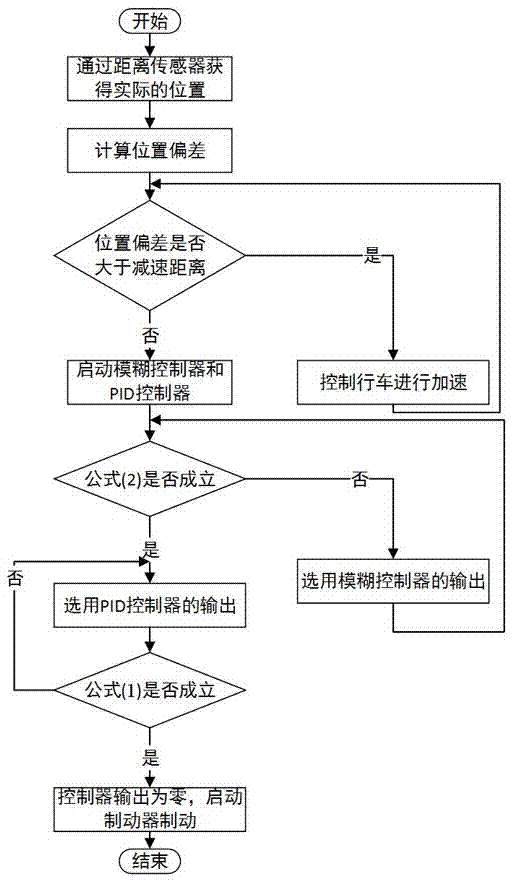

[0031] Such as Figures 1 to 2As shown, an embodiment of the control system of the present invention includes a brake 1, a traveling frequency converter 2 and a traveling motor 3, the output ends of the brake 1 and the traveling motor 3 are connected to the driving 4, and the output terminals of the traveling frequency converter 2 Linked to the input end of the travel motor 3, also includes

[0032] The distance positioning sensor 5 is used to measure the actual distance y traveled by the vehicle 4;

[0033] Driving controller 6, described driving controller 6 comprises seeking difference module 8, first selection unit 9, acceleration controller 11, deceleration controller 7, braking controller 10, the output terminal of distance positioning sensor 5 and seeking module 8 is connected to the input end, the output end of the difference module 8 is connected to the input end of the brake controller 10 and the first selection unit 9 respectively, the output end of the brake contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com