A few-mode fiber

A technology of few-mode fiber and fiber, applied in clad fiber, multi-core fiber, micro-structure fiber, etc., can solve the problems of large bending loss, difficult work, G.652 fiber can not meet the requirements, etc., and achieve low bending loss transmission , maintain low-loss transmission, and achieve the effect of single-mode operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

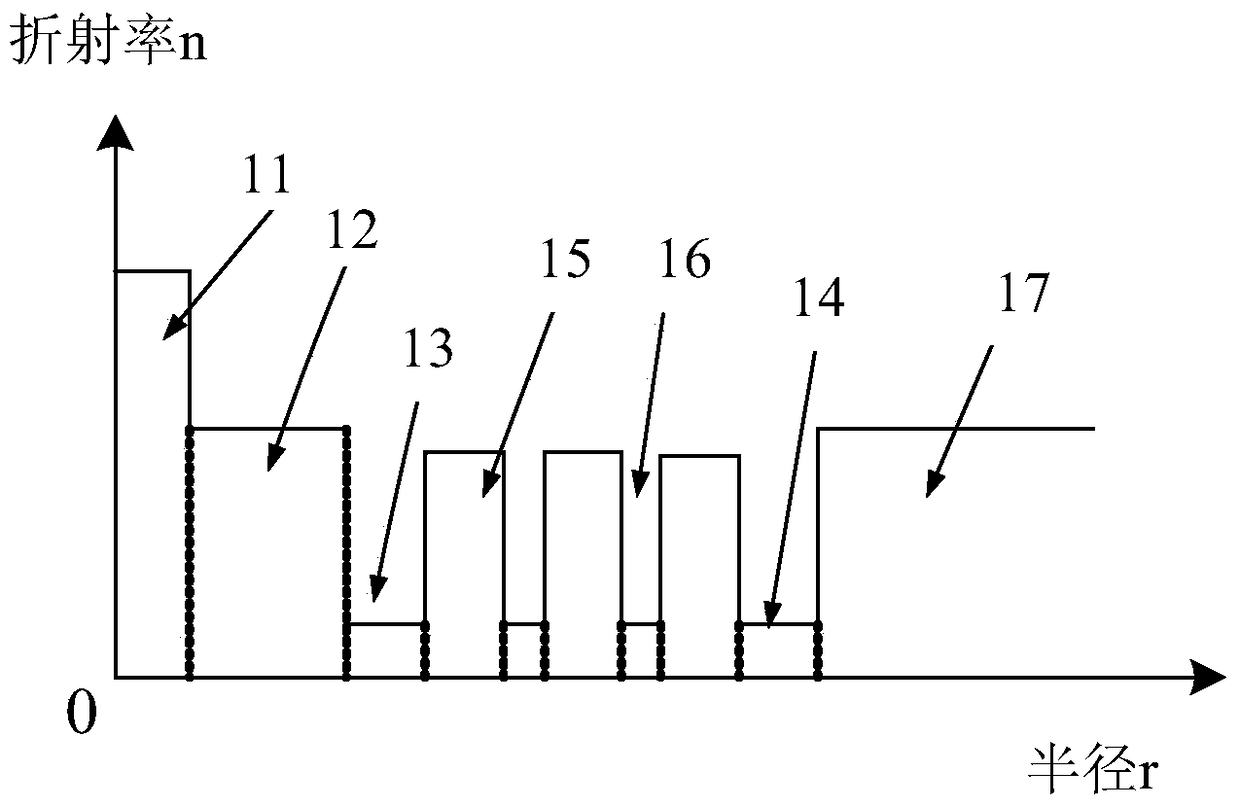

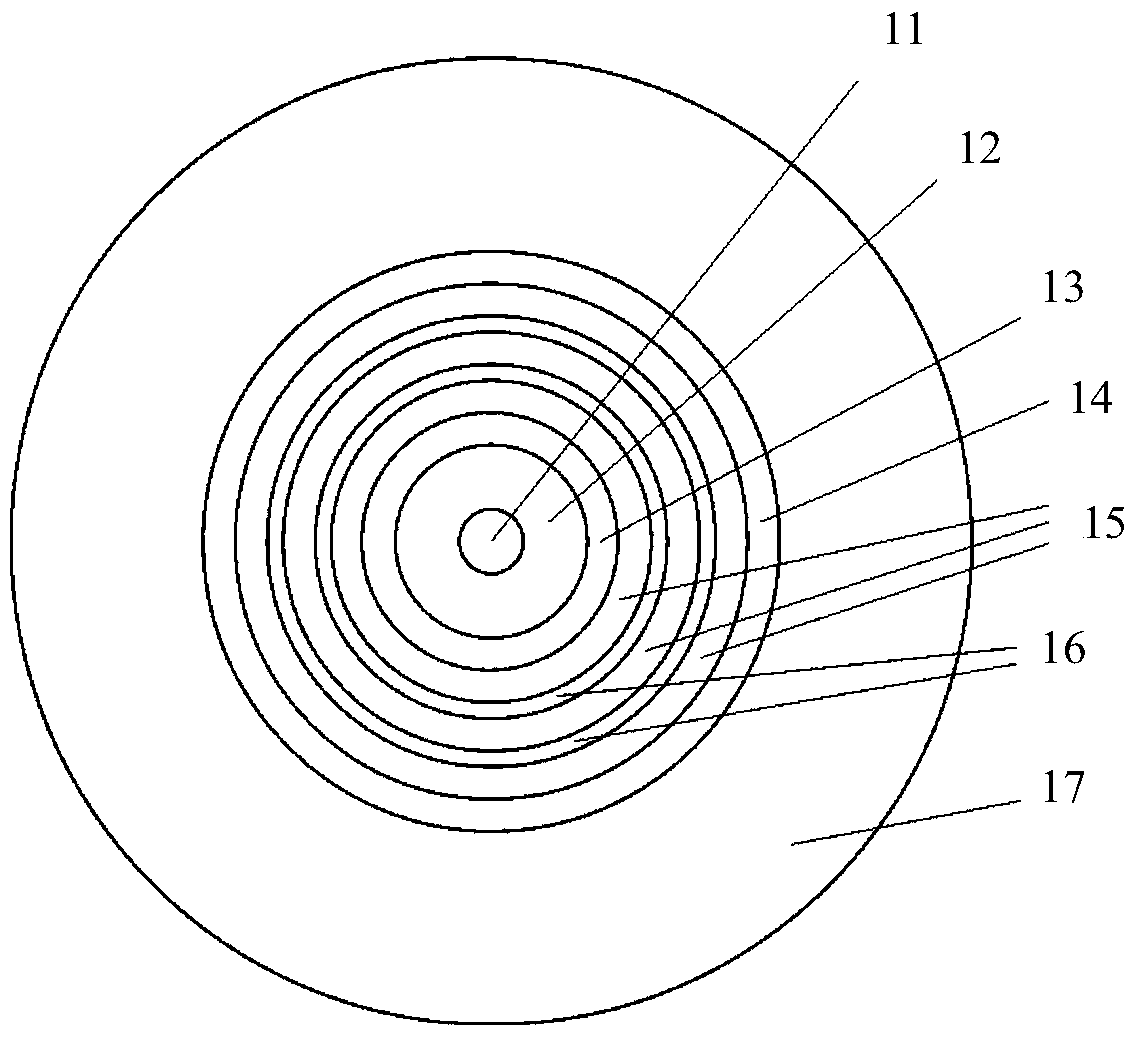

[0052] The radius a of the inner core 11 1 =4.1μm, the radial width a of the outer core 12 2 = 6 μm. The radial width of the adjacent low refractive index layer 13 is 3 μm, the radial width of the adjacent low refractive index layer 14 is 3 μm, the radial width of the high refractive index filter layer 15 is 3 μm, and the radial width of the low refractive index filter layer 16 is 2 μm. The high-refractive index filter layer 15 and the low-refractive index filter layer 16 are three layers and two layers respectively, and the optical fiber structure is shown in FIG. 2 . Inner core 11, outer core 12, core-adjacent low-refractive index layer 13, adjacent-wrap low-refractive-index layer 14, high-refractive-index filter mode layer 15, low-refraction-index filter mode layer 16 and outer cladding layer 17. 1 ,n 2 ,n 3 ,n 4 ,n 5 ,n 6 ,n 7 Satisfied between: n 1 -n 2 =0.005, n 2 -n 3 =0.004, n 2 -n 5 =0.002,n 3 =n 4 =n 6 , n 2 =n 7 .

[0053] When the optical wavel...

Embodiment 2

[0055] The radius a of the inner core 11 1 =4μm, the radial width a of the outer core 12 2 = 6 μm. The radial width of the adjacent low refractive index layer 13 is 3 μm, the radial width of the adjacent low refractive index layer 14 is 3 μm, the radial width of the high refractive index filter layer 15 is 3 μm, and the radial width of the low refractive index filter layer 16 is 2 μm. The high refractive index filter layer 15 and the low refractive index filter layer 16 are two layers and one layer respectively. Inner core 11, outer core 12, core-adjacent low-refractive index layer 13, adjacent-wrap low-refractive-index layer 14, high-refractive-index filter mode layer 15, low-refraction-index filter mode layer 16 and outer cladding layer 17. 1 ,n 2 ,n 3 ,n 4 ,n 5 ,n 6 ,n 7 Satisfied between: n 1 -n 2 =0.005, n 2 -n 3 =0.007, n 2 -n 5 =-0.001, n 3 =n 4 =n 6 , n 2 =n 7 .

[0056] When the optical wavelength is 1550nm, when the bending radius of the optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com