An electrostatic adsorption-based lubricating oil detection device for reducers and its application method

A technology of electrostatic adsorption and detection device, applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc., can solve the problems of reducing maintenance cost, difficult to ensure the lubrication performance of reducer, etc., to increase maintenance cost, easy to use, measurement Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

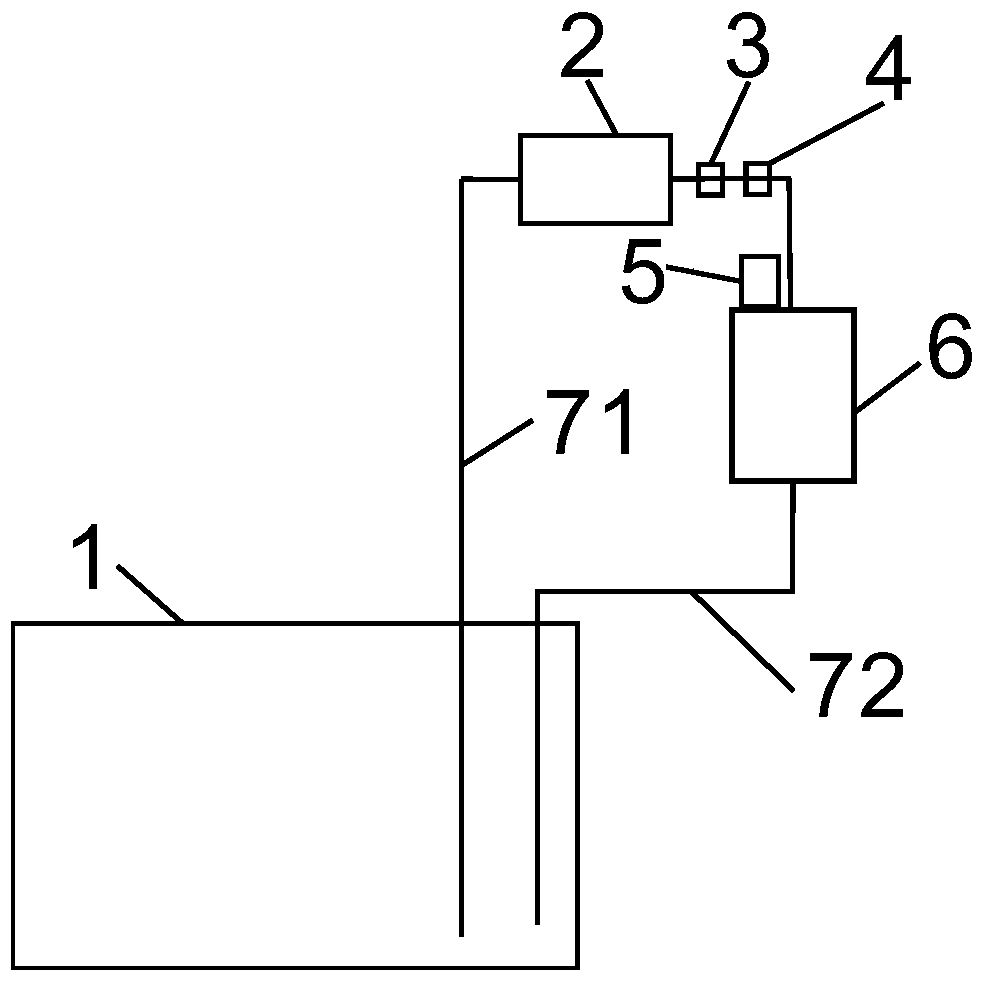

[0036] Such as figure 1 As shown, a decelerator lubricating oil detection device based on electrostatic adsorption includes a first oil pipe 71, one end of the first oil pipe 71 is immersed in lubricating oil, and the other end of the first oil pipe 71 is connected to the inlet of the oil pumping device 2. The liquid port is connected, and the liquid outlet of the oil pumping device 2 is connected with one end of the second oil pipe 72, and the second oil pipe 72 returns to the reducer box again, and the temperature sensor 3 and the conductivity sensor 3 are installed in the second oil pipe 72. The sensor 4, the second oil pipe 72 is also provided with an electrostatic adsorption device 6, the electrostatic adsorption device 6 is arranged on the quality detection device 5, and absorbs and weighs the impurities in the lubricating oil of the reducer through the principle of electrostatic adsorption to obtain a reducer Lubricating oil impurity content.

[0037]One end of the fir...

Embodiment 2

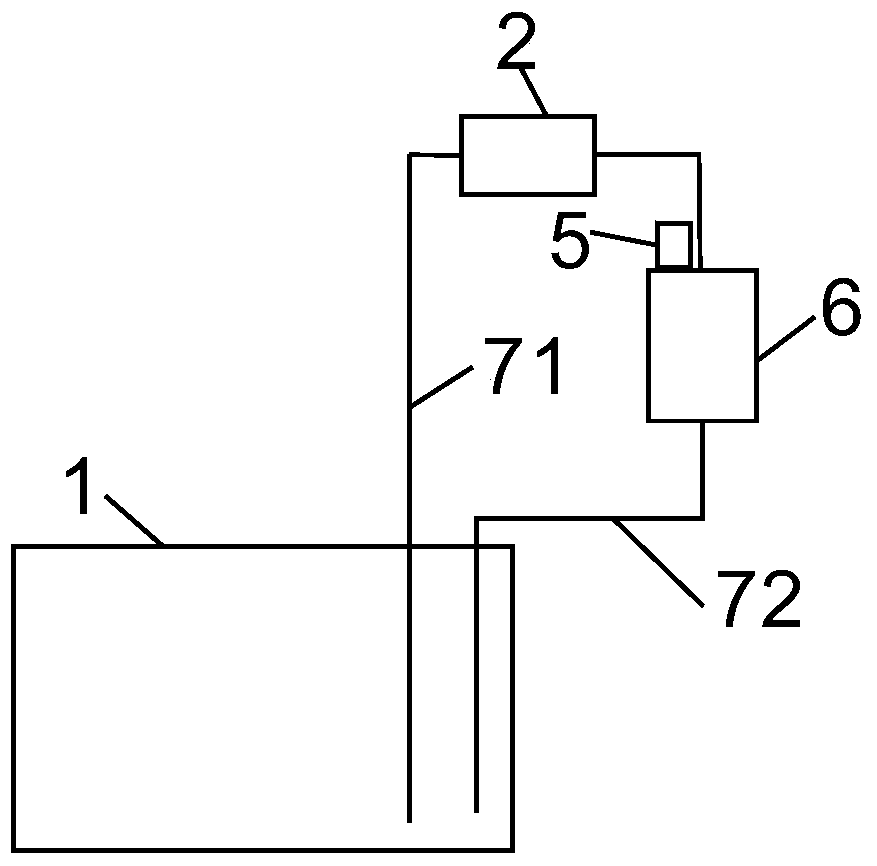

[0050] like figure 2 As shown, a decelerator lubricating oil detection device based on electrostatic adsorption includes a first oil pipe 71, one end of the first oil pipe 71 is immersed in lubricating oil, and the other end of the first oil pipe 71 is connected to the inlet of the oil pumping device 2. The liquid port is connected, and the liquid outlet of the oil pumping device 2 is connected to one end of the second oil pipe 72, and the second oil pipe 72 is also provided with an electrostatic adsorption device 6, which is arranged on the quality detection device 5, The impurities in the lubricating oil of the reducer are adsorbed and weighed by the principle of electrostatic adsorption to obtain the impurity content of the lubricating oil of the reducer.

[0051] In this scheme, one end of the first oil pipe 71 is immersed in lubricating oil, the other end of the first oil pipe 71 is connected with the liquid inlet of the oil pumping device 2, and the liquid outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com