A vertical pump with bearing self-lubricating function

A vertical pump, self-lubricating technology, applied in the direction of bearing components, shafts and bearings, non-variable pumps, etc., can solve the problems of restricting the market adaptability of vertical pumps, using a small span of power range, increasing production costs, etc. Achieve the effect of improving lubrication efficiency and application flexibility, improving work flexibility, and high structure compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

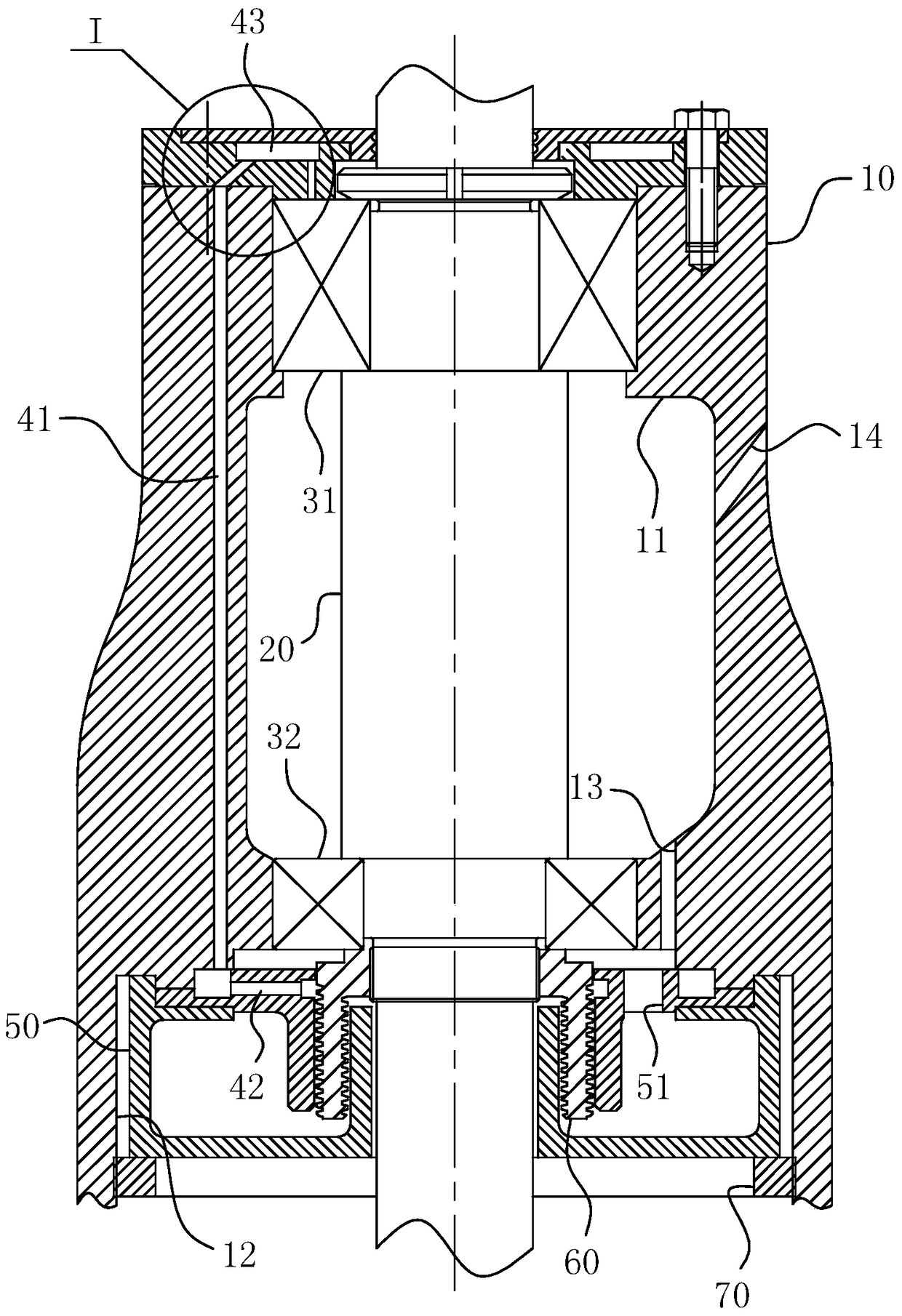

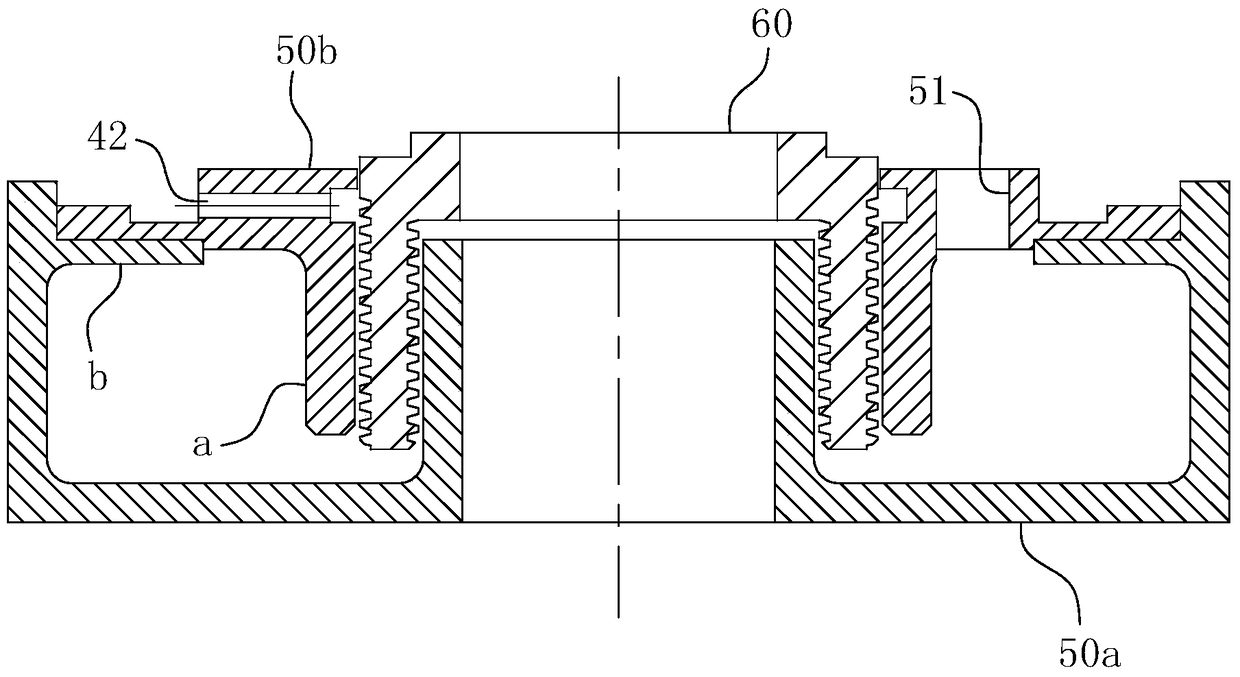

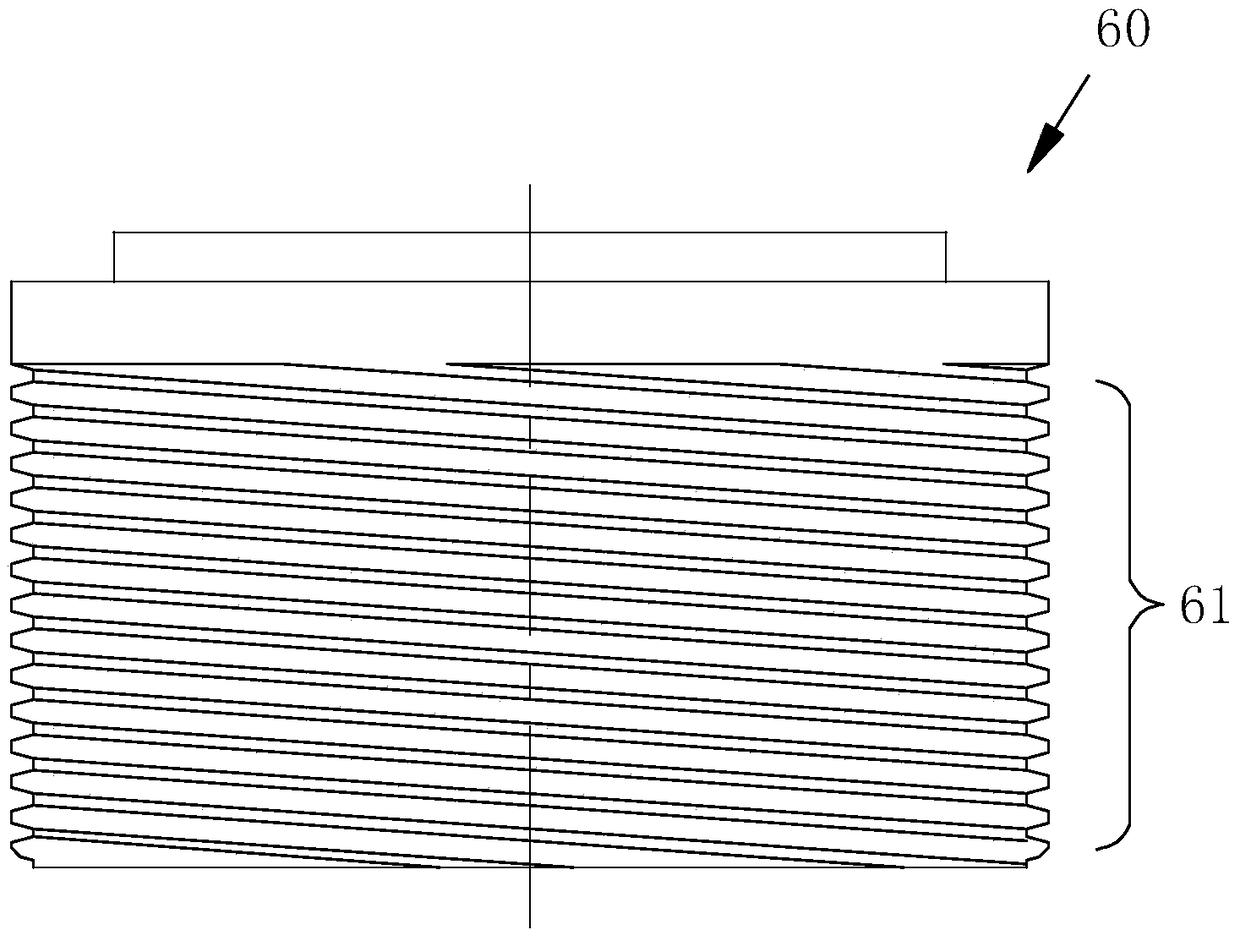

[0033] For ease of understanding, combined here Figure 1-4 One of the specific implementation structure and work flow of the present invention is described as follows:

[0034] Concrete working structure of the present invention, as figure 1 and image 3 As shown, it is mainly assembled from the following components: a pump casing 10 constituting the main base, the pump casing 10 has a vertical pump chamber 11, and an oil injection hole 14 is opened on the side wall of the pump chamber 11. The pump shaft 20 is arranged in the pump cavity 11 , and the pump shaft 20 is supported by the upper bearing 31 and the lower bearing 32 to be fixed in the pump cavity 11 . The upper bearing 31 is fixed by the conventional spigot of the pump chamber 11 and the upper gland structure. The outer ring of the lower bearing 32 is fixed on the wall of the corresponding hole of the pump chamber 11, and the upper end of the lower bearing 32 realizes the joint fit to limit its overall upward move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com