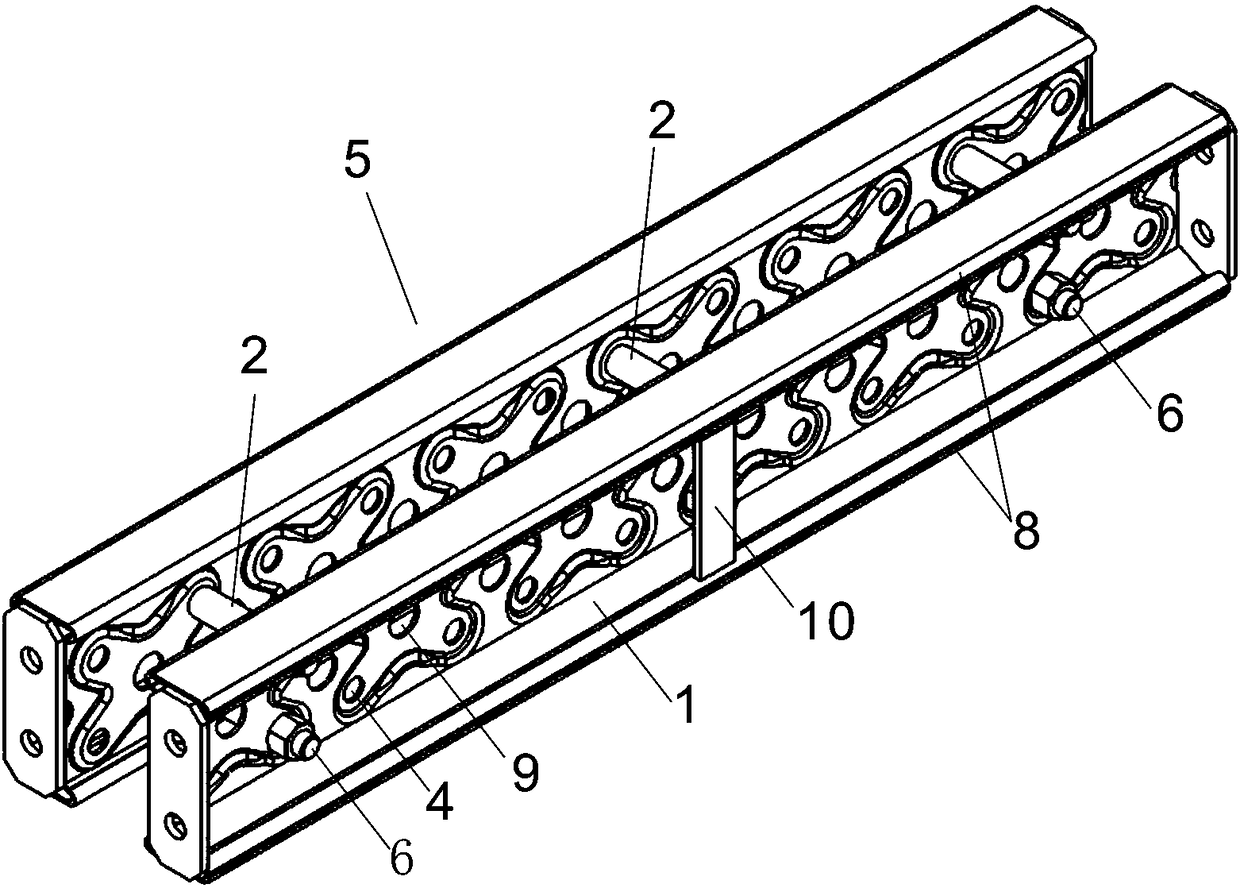

A steel-wood composite I-beam

A technology of steel-wood combination and I-beam, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problems of reducing the production efficiency of wooden beams and Economic effect, low reuse rate, high production cost and other problems, to achieve the effect of high construction efficiency, reliable quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

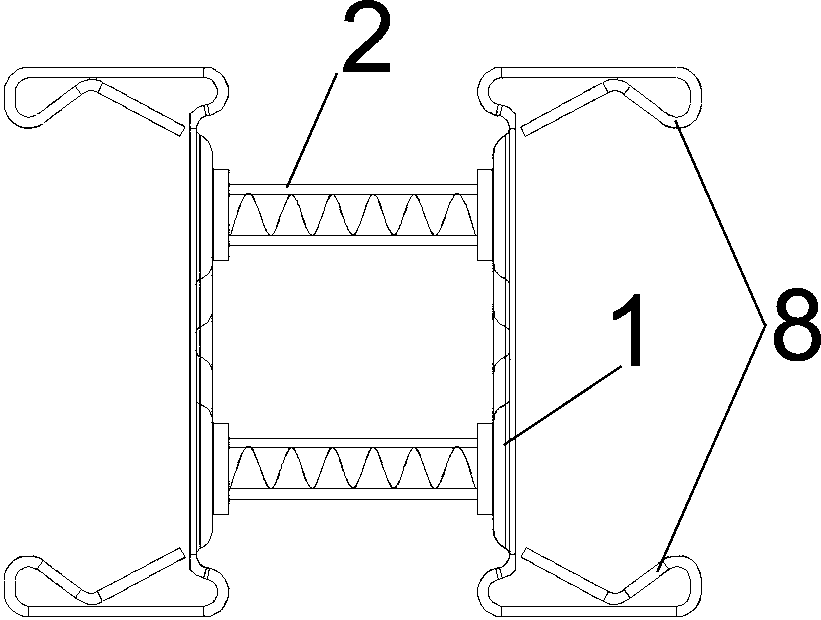

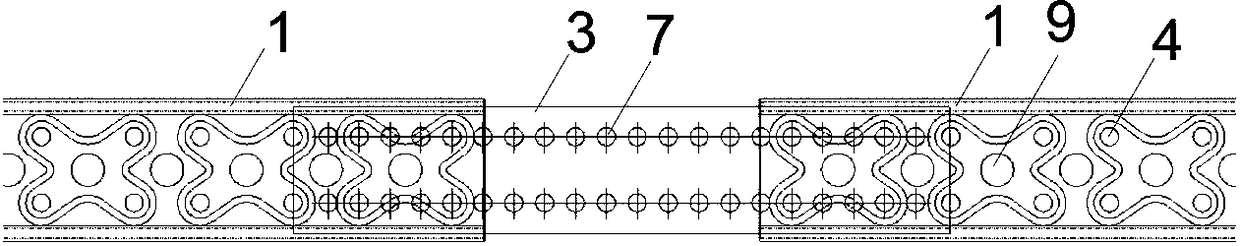

[0016] Embodiment: The material of the double C-shaped steel 1 of the present invention is Q345, which is a thin-walled hemming structure. The surface is galvanized and anti-corrosion treated. Weld the wooden square connecting plates 4 horizontally with a certain distance between them, embed the long wooden square 2 on the upper part of the double C-shaped steel, and fix the wooden square 2 on the wooden square connecting plate 4 with screws 6; under the wooden square 2 Use rivets 7 to vertically fix the reinforcing plate 5 on the double C-shaped steel 1 to improve the overall stability of the I-beam; the end fixing part 3 is a forged component, which is installed and fixed on the two ends of the double C-shaped steel 1 to strengthen the beam. overall stability of the body. Waist-shaped holes 11 are arranged in parallel at a certain distance on the opposite sides of the double C-shaped steel web, and a T-shaped notch is formed at the bottom of the lower flange of the double C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com