Semi-automatic height-adjusting support and adjusting method thereof

A semi-automatic, height-adjusting technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of low work efficiency, limited operation space, inconvenient operation, etc., and achieve the effect of high labor efficiency and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

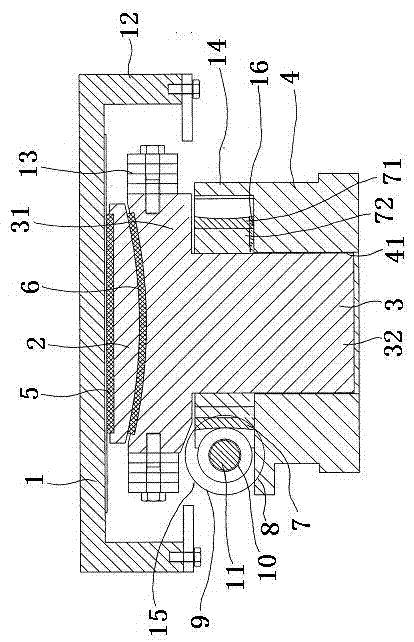

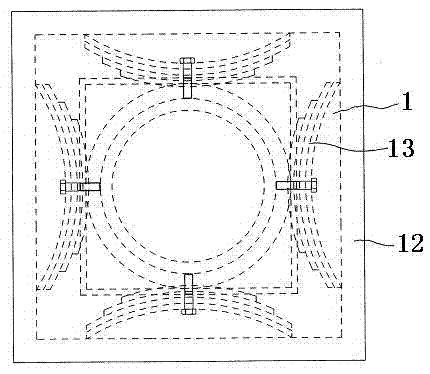

[0023] The structure and operating principle of the semi-automatic height-adjusting support of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] like figure 1 , 2 As shown, the semi-automatic height-adjusting support of the present invention includes an upper seat plate 1, a ball core 2, a middle seat plate 3 and a lower seat plate 4 at the upper end, and a plane slide plate 5 is arranged between the ball core 2 and the upper seat plate 1. A spherical slide 6 is arranged between the seat plate 3 and the ball core 2. The middle seat plate 3 includes a top plate 31 at the upper end and a column 32 at the lower end. There is a column hole 41 in the center of the lower seat plate 4, and the column 32 is inserted into the column hole 41. A turbine 7 and a worm 8 matched with the turbine 7 are arranged on the outside of the column 32 above the column hole 41. The turbine 7 is screwed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com